Preparation method and application for S2O8<2->/ZrO2-SiO2 solid acid catalyst

A solid acid catalyst and carrier technology, applied in the preparation of organic compounds, physical/chemical process catalysts, carboxylate preparation, etc., can solve the problems of easy-to-corrosion equipment, many side reactions, easy coloring of products, etc., and achieve good selectivity , High catalytic activity, avoiding the effect of high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

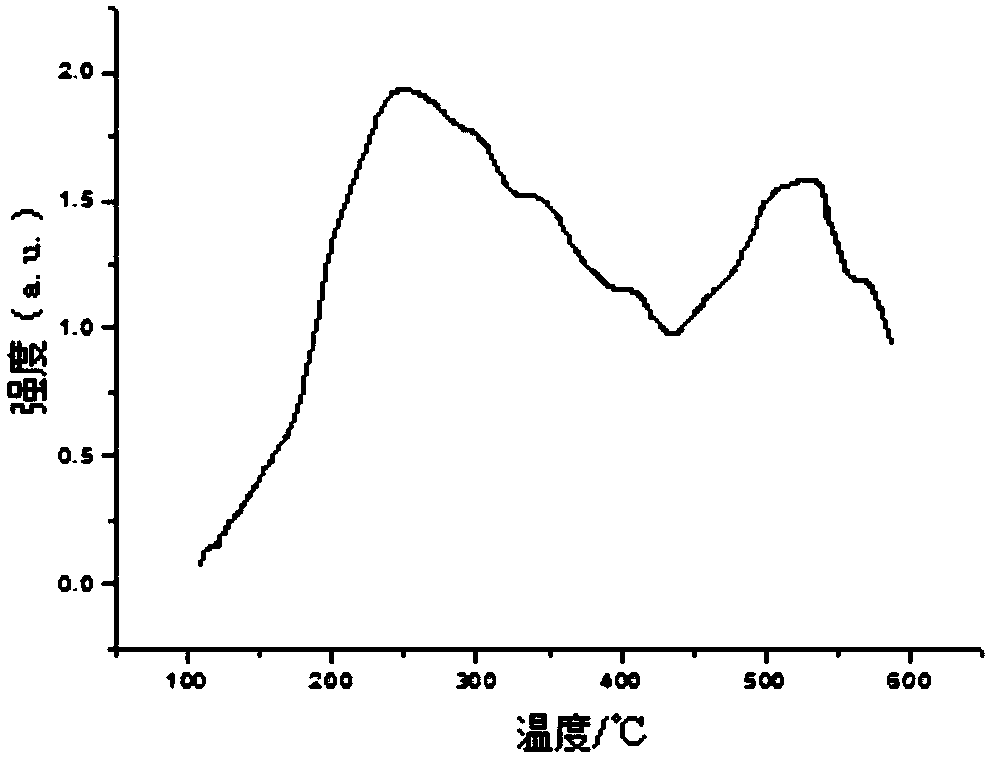

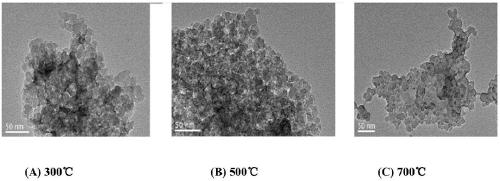

Image

Examples

Embodiment 1

[0021] Dissolve 16.10 g of zirconium oxychloride octahydrate with 72.92 g of deionized water, add it into a three-necked flask equipped with mechanical stirring, stir vigorously and adjust the pH to about 2 with concentrated ammonia water, add 20.03 g of silica sol, and crystallize at 75 ° C Add concentrated ammonia water until complete precipitation, crystallize for 3 hours, filter with suction to obtain a solid precipitate, wash with deionized water 3 times, each time 200mL, dry at 100°C to constant weight, grind, and Calcined in the furnace at 500°C for 5h to obtain ZrO 2 -SiO 2 The carrier was then impregnated with 29.53g of 1.5mol / L ammonium persulfate for 24h, dried and ground, and calcined in a muffle furnace at 500°C for 5h to obtain S 2 o 8 2- / ZrO 2 -SiO 2 A solid acid catalyst, wherein the molar ratio n (Zr:Si) of zirconium to silicon is 1:2.

[0022] This catalyst is used to catalyze the direct esterification reaction that the raw material molar ratio is MAA:...

Embodiment 2

[0024] The basic preparation method is the same as in Example 1, and the difference is that the zirconium oxychloride octahydrate add-on is 14.49g, and the silica sol add-on is 27.04g, wherein said zirconium, silicon molar ratio n (Zr: Si) is 1: 3.

[0025] This catalyst is used to catalyze the direct esterification reaction that the raw material molar ratio is MAA:2EY=1.3:1, and the catalyst consumption is 5% of raw material gross mass, and the water carrying agent consumption is 15% of raw raw material gross mass, and the polymerization inhibitor consumption is 0.5% of the total mass of raw materials, the reaction temperature is 155°C, the reaction time is 8h, the conversion rate of 2EY is 92.68%, and the yield of MED is 91.92%.

Embodiment 3

[0027] The basic preparation method is the same as in Example 1, and the difference is that the zirconium oxychloride octahydrate add-on is 12.88g, and the silica sol add-on is 32.04g, wherein said zirconium, silicon molar ratio n (Zr: Si) is 1: 4.

[0028] This catalyst is used to catalyze the direct esterification reaction that the raw material molar ratio is MAA:2EY=1.3:1, and the catalyst consumption is 5% of raw material gross mass, and the water carrying agent consumption is 15% of raw raw material gross mass, and the polymerization inhibitor consumption is 0.5% of the total mass of raw materials, the reaction temperature is 155°C, the reaction time is 8h, the conversion rate of 2EY is 99.58%, and the yield of MED is 93.81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com