Selective hydrogenation catalyst for unsaturated ketone and preparation method and application thereof

A hydrogenation catalyst and selective technology, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of poor catalytic stability of hydrogenation catalysts, and achieve excellent catalytic performance and stability , high catalytic activity and strong sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh 1g of carboxymethyl chitin and disperse in 50ml of water, add 1g of F127 and stir well. Then add 1g of cerium nitrate hexahydrate and 1ml of nitric acid, mix well, and stir until dry at 80°C; then, transfer to a 30ml crucible, and perform calcination in a nitrogen furnace. The specific calcination process is: heat up to 1000°C at 5°C / min , calcined at 1000 ° C for 1 h; then, naturally cooled to room temperature. The calcined mixture is pulverized to obtain a highly dispersed cerium oxide composite nitrogen-doped carbon material. Weigh 1 g of the above material, add it to 60 mL of deionized water, slowly add 1 mL of PdCl with a concentration of 10 mg / mL 2 solution, stirred at 50°C for 12h, dried in an oven at 70°C for 24h, calcined in air at 300°C for 1h, and reduced with hydrogen at 300°C for 1h (hydrogen flow rate 50mL / min, heating rate 5°C / min) to obtain unsaturated ketone Selective hydrogenation catalyst.

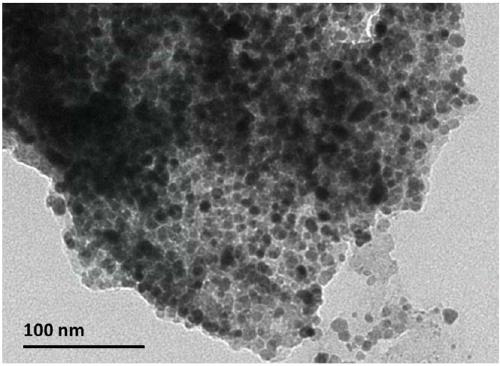

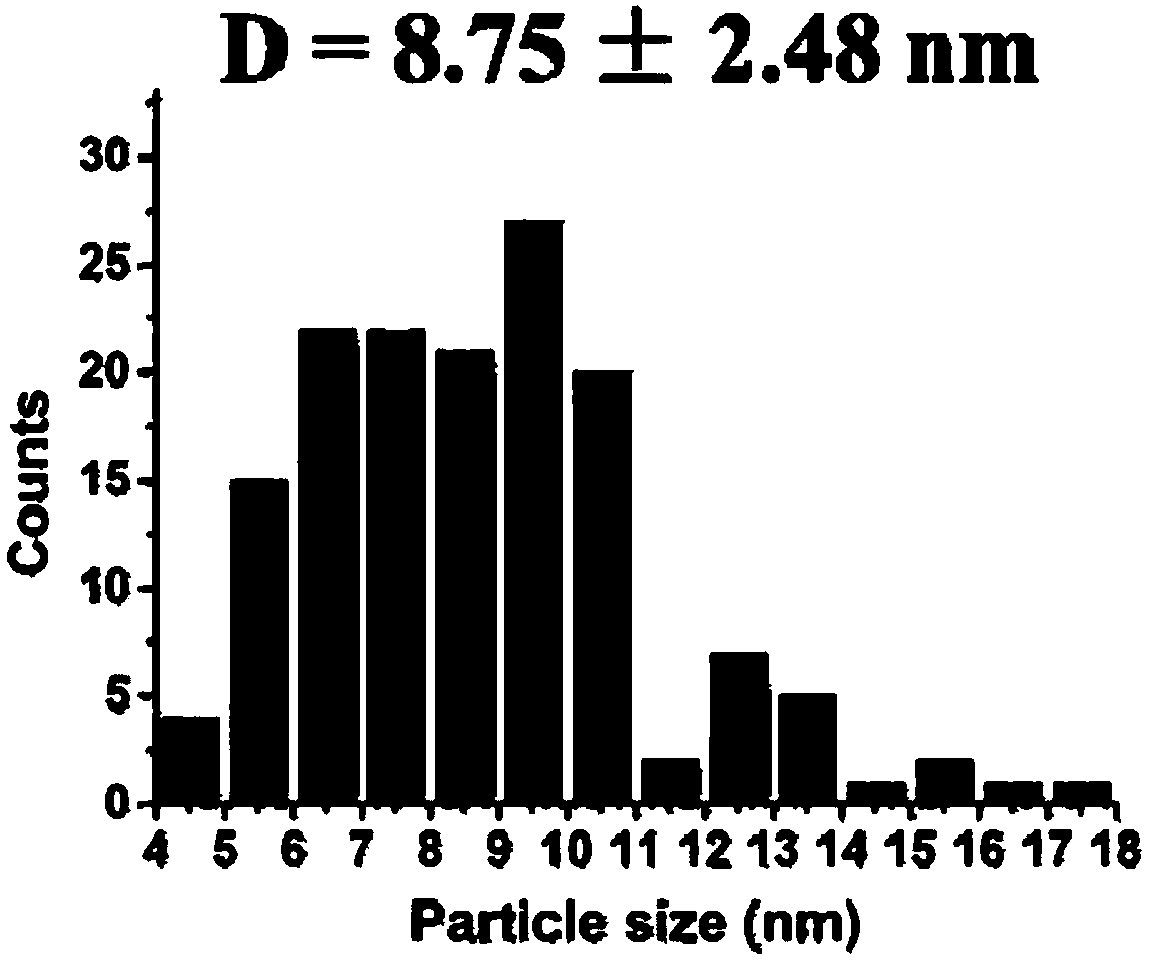

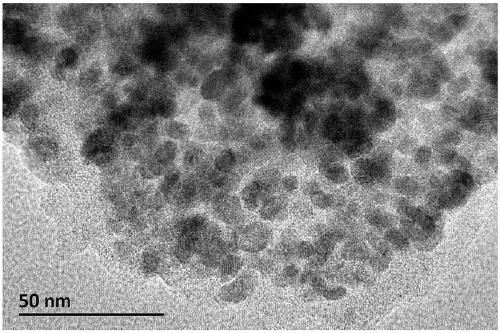

[0046] figure 1 with image 3 The transmission el...

Embodiment 2

[0048] Weigh 1g of carboxymethyl chitosan and disperse it in 50ml of water, add 1g of F127 and stir evenly. Then add 1g of cerium nitrate hexahydrate and 1ml of nitric acid, mix well, and stir until dry at 80°C; then, transfer to a 30ml crucible, and perform calcination in a nitrogen furnace. The specific calcination process is: heat up to 1000°C at 5°C / min , calcined at 1000 ° C for 1 h; then, naturally cooled to room temperature. The calcined mixture is pulverized to obtain a highly dispersed cerium oxide composite nitrogen-doped carbon material. Weigh 1 g of the above material, add it to 60 mL of deionized water, slowly add 1 mL of 10 mg / mL PdCl 2 solution, stirred at 50°C for 12h, dried in an oven at 70°C for 24h, calcined in air at 300°C for 1h, and reduced with hydrogen at 300°C for 1h (hydrogen flow rate: 50mL / min, heating rate: 5°C / min) to obtain unsaturated ketone Selective hydrogenation catalyst. The dispersion of Pd measured by CO titration is 81%, and the specif...

Embodiment 3

[0050] Weigh 1g of carboxymethyl chitin and dissolve in 50ml of water, add 1g of F127 and stir well. Then add 1g of zirconium nitrate pentahydrate and 1ml of nitric acid and mix evenly, stir until dry at 80°C; then, transfer to a 30ml crucible and calcinate in a nitrogen furnace. The specific calcining process is: heat up to 1000 ℃, calcined at 1000℃ for 1h; then, cool down to room temperature naturally. The calcined mixture is pulverized to obtain a highly dispersed zirconia composite nitrogen-doped carbon material. Weigh 1 g of the above material, add it to 60 mL of deionized water, slowly add 1 mL of 10 mg / mL PdCl 2 solution, stirred at 50°C for 12h, dried in an oven at 70°C for 24h, calcined in air at 300°C for 1h, and reduced with hydrogen at 300°C for 1h (hydrogen flow rate: 50mL / min, heating rate: 5°C / min) to obtain unsaturated ketone Selective hydrogenation catalyst. The dispersion of Pd measured by CO titration is 79%, and the specific surface area of the catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com