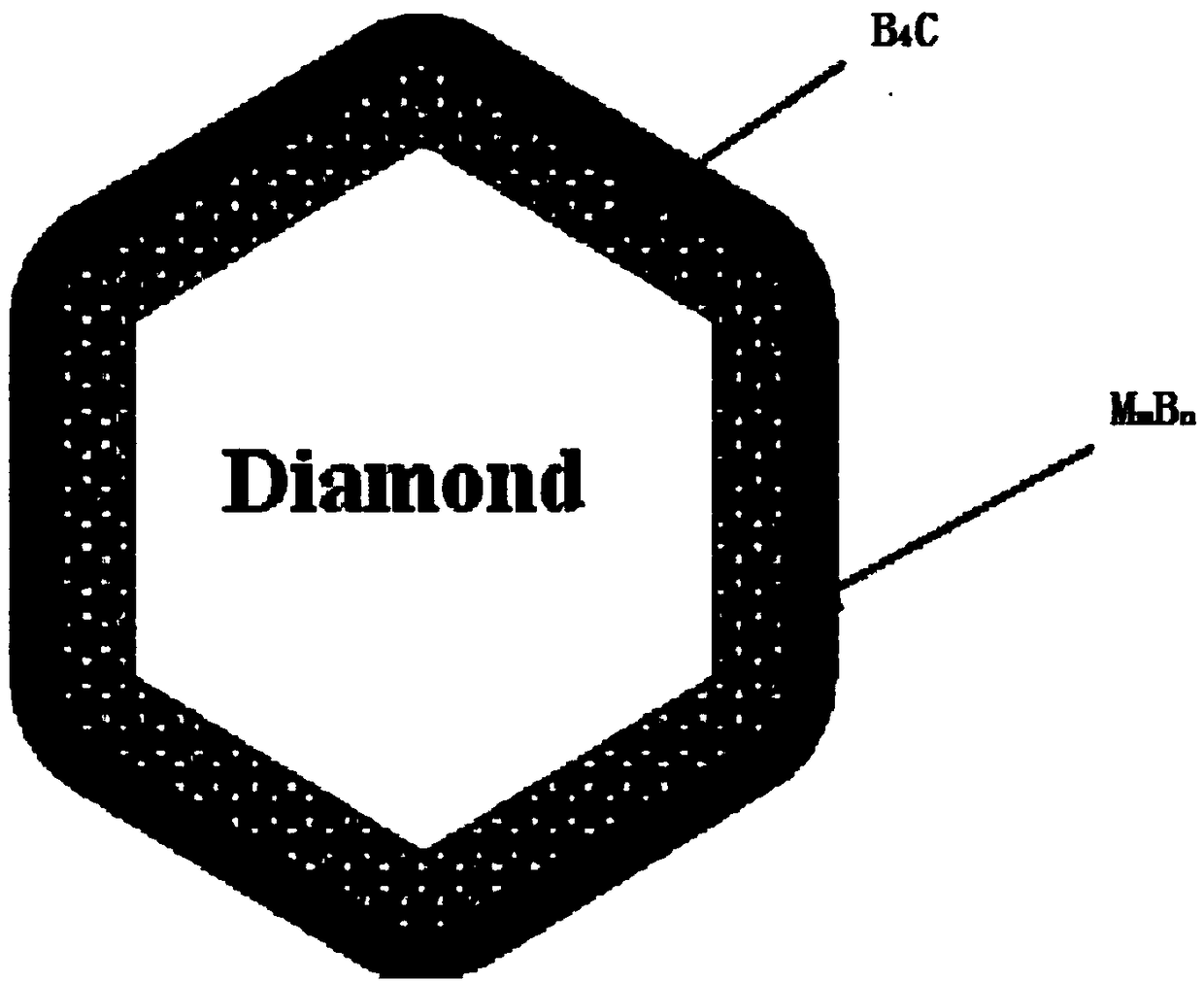

Preparation method for coating surface of diamond with boron-alloy plating layer

A surface coating, boron alloy technology, used in metal processing equipment, coating, transportation and packaging, etc., can solve the problems of high equipment cost, low bonding strength, difficult to control the uniformity of the coating surface, etc. Wetness, the effect of improving interfacial bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

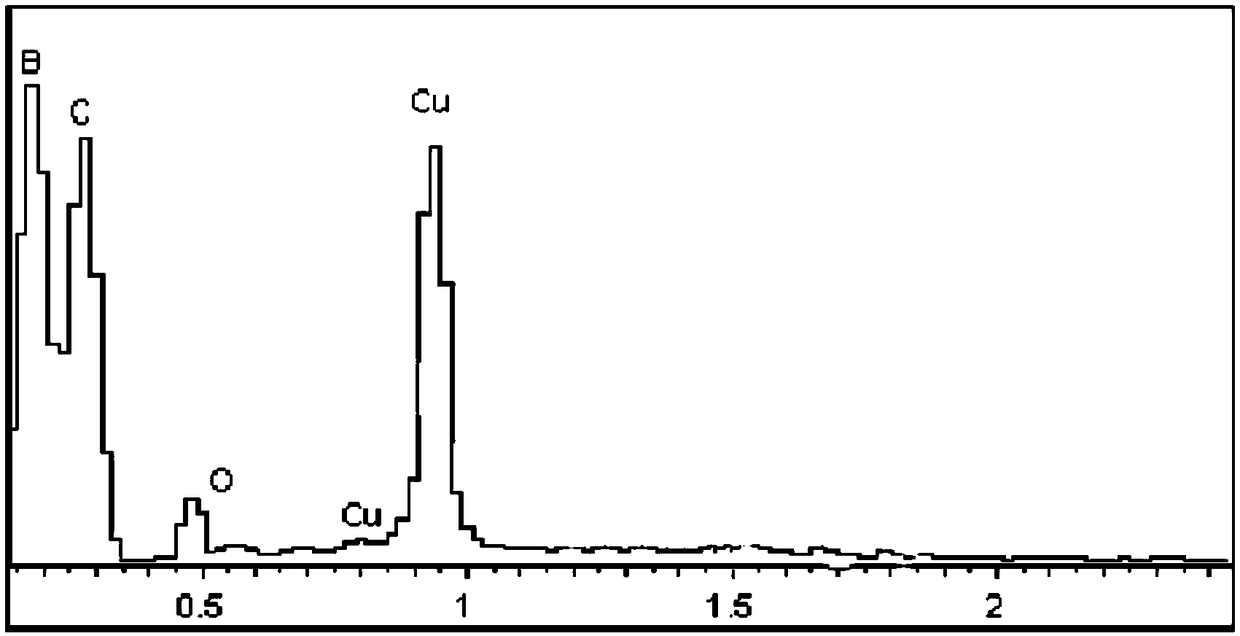

[0025] A method for preparing a diamond surface-coated boron alloy coating, comprising the steps of:

[0026] S1. Soak diamond micropowder with a particle size of 200 μm in dilute sulfuric acid solution, heat and stir at 70°C for 80 minutes, filter and rinse repeatedly with distilled water until the pH of the washing solution is 7, then use acetone to ultrasonically clean for 30 minutes, and then use distilled water to ultrasonically clean After filtering for 20 minutes, rinse with absolute ethanol for 3 times, and then vacuum dry to obtain the cleaned diamond powder; add the cleaned diamond powder and amorphous boron powder with a particle size of 1 μm into the high-speed mixer at a mass ratio of 10:0.5 Mix evenly, install the evenly mixed powder in a graphite crucible, put it into a vacuum carbon tube furnace, and evacuate until the vacuum degree reaches 10 -3 After the temperature is below Pa, raise the temperature to 1150°C and keep it warm for 40 minutes to react. After c...

Embodiment 2

[0030] A method for preparing a diamond surface-coated boron alloy coating, comprising the steps of:

[0031] S1. Soak diamond micropowder with a particle size of 50 μm in dilute sulfuric acid solution, heat and stir at 80°C for 60 minutes, filter and rinse repeatedly with distilled water until the pH of the washing solution is 7, then use acetone to ultrasonically clean for 30 minutes, and then use distilled water to ultrasonically clean After filtering for 30 minutes, rinse with absolute ethanol twice, and then vacuum dry to obtain the cleaned diamond powder; add the cleaned diamond powder and amorphous boron powder with a particle size of 1 μm into the high-speed mixer at a mass ratio of 10:1 Mix evenly, install the evenly mixed powder blend in a graphite crucible, put it in a vacuum carbon tube furnace, and vacuum until the vacuum degree reaches 10 -3 After the temperature is below Pa, raise the temperature to 1050°C and keep it warm for 60 minutes. After cooling to room t...

Embodiment 3

[0034] A method for preparing a diamond surface-coated boron alloy coating, comprising the steps of:

[0035] S1. Soak diamond micropowder with a particle size of 500 μm in dilute sulfuric acid solution, heat and stir at 60°C for 90 minutes, filter and rinse repeatedly with distilled water until the pH of the washing solution is 6, then use acetone to ultrasonically clean for 60 minutes, and then use distilled water to ultrasonically clean After filtering for 10 minutes, rinse with absolute ethanol for 4 times, and then vacuum-dry to obtain the cleaned diamond powder; add the cleaned diamond powder and amorphous boron powder with a particle size of 10 μm into the high-speed mixer at a mass ratio of 10:0.5 After mixing evenly, install the uniformly mixed powder blend in a graphite crucible, put it into a vacuum carbon tube furnace, and vacuum until the vacuum degree reaches 10 -3 After the temperature is below Pa, raise the temperature to 1250°C and keep it warm for 30 minutes....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com