Method for preparing polymer by atom transfer radical polymerization catalyzed by cyclic iron salts at room temperature

A technology of polymer and polymer solution, applied in chemical recovery and other directions, can solve the problems of unusable, high temperature, and inability to recover pure catalyst, and achieve the effect of low metal residue, good catalytic efficiency and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

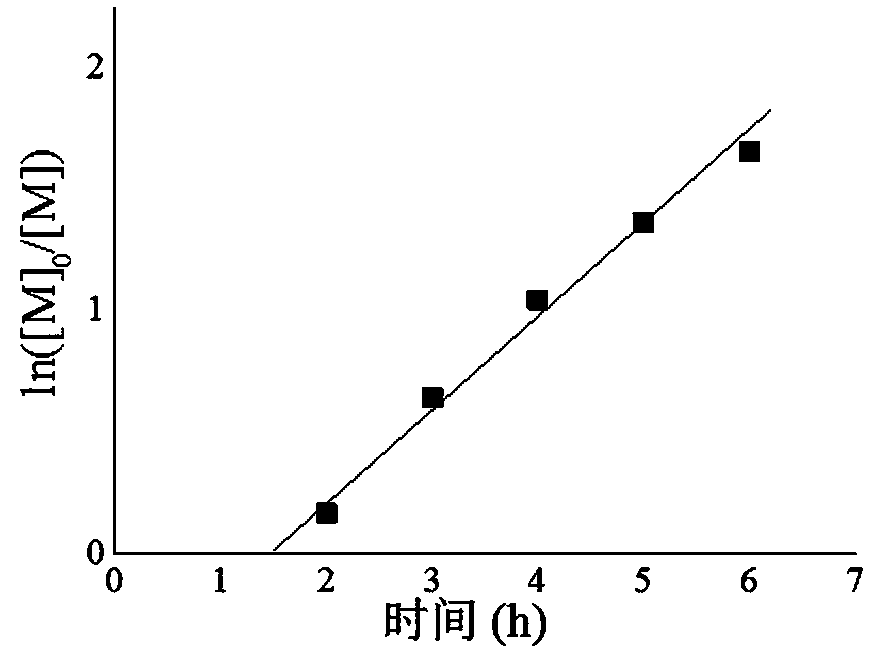

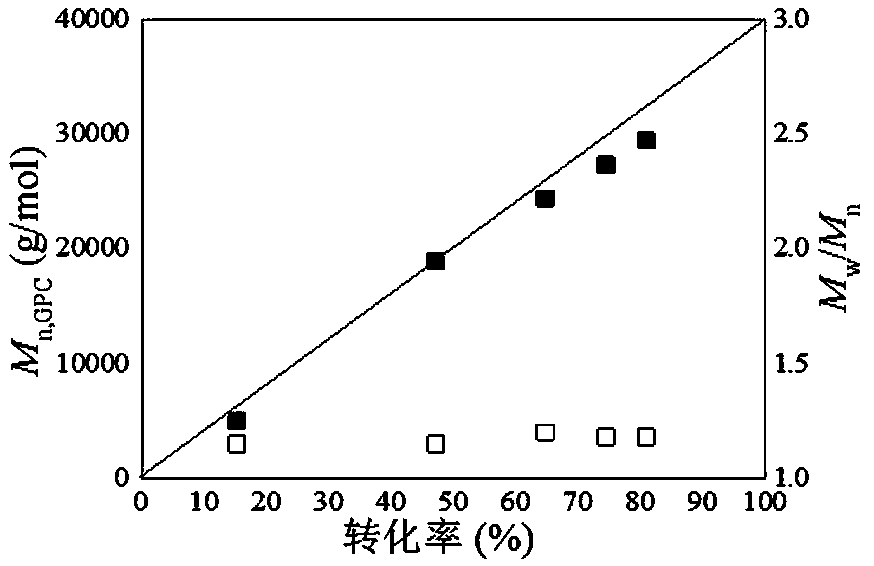

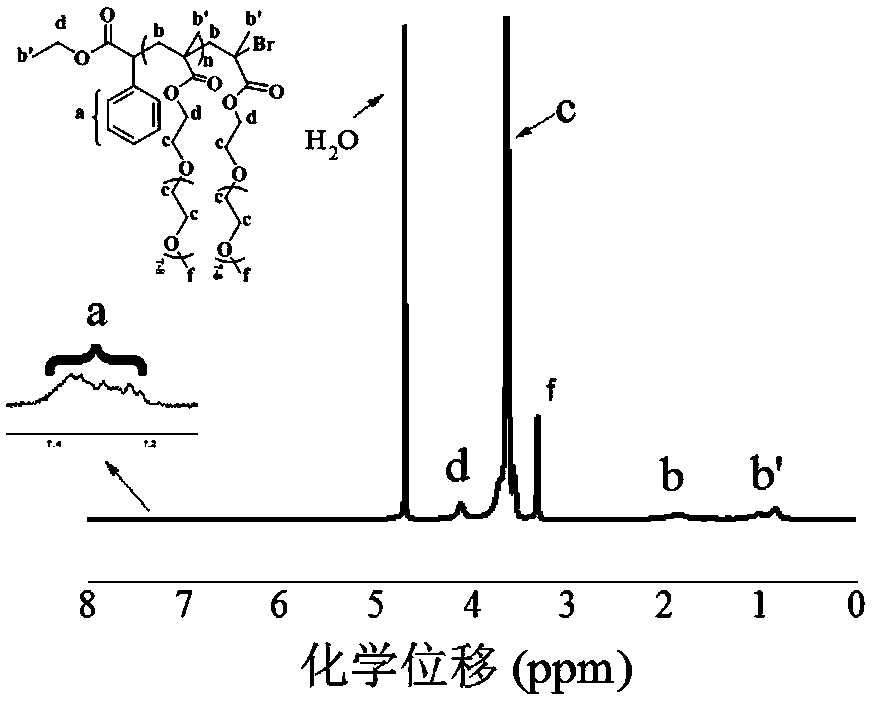

[0038] Embodiment 1: Catalyst recovery method in the atom transfer radical polymerization catalyzed by iron salt at room temperature

[0039] Water-soluble monomer mPEGMA 500 (1.0 mL, 2.1 mmol), initiator EBPA (4.6 μL, 2.6×10 -2 mmol), catalyst iron tetraphenylporphyrin Fe(III)-TPP (7.5 mg, 1.1×10 -2 mmol), ligand n-butylammonium bromide TBA-Br (20.5 mg, 6.3×10 -2 mmol), UV photoinitiator TPO were added to 5 mL ampoule, then p-xylene (1.0 mL) and absolute ethanol (1.0 mL) were added to it, the tube was melted and sealed, and the temperature of the ampoule was transferred to room temperature The polymerization was carried out under the condition of magnetic stirring under the ultraviolet lamp. Break the tube after the scheduled polymerization time (4 h), and add pure water (1.0 mL) to induce the separation of the catalyst-dissolved p-xylene phase and the polymer-dissolved ethanol phase, and remove the upper p-xylene layer For recycling, the remaining ethanol layer is dia...

Embodiment 2

[0054] Embodiment 2: the recycling experiment of catalyst

[0055] The present invention is characterized in that it can keep the metal residues in the polymer extremely low after polymerization, and can recycle the catalyst. After the polymerization, the upper p-xylene phase (dissolved with the catalyst) is taken out and placed in another equal-volume In a clean ampoule, just add a predetermined amount of monomer, initiator, ligand, UV photoinitiator and predetermined volume of ethanol (the amount of the remaining components added in this recovery experiment is equal to that before recovery), and then the next round of aggregation. The single-point experiments under different recovery times are shown in Table 2.

[0056] Table 2 Comparison of single-point polymerization experiments under different recycling times

[0057] usage count

Conversion rates(%)

Theoretical molecular weight (g / mol)

GPC molecular weight (g / mol)

PDI

Metal residue in polyme...

Embodiment 3

[0060] Embodiment 3: Catalyst recovery method in the atom transfer radical polymerization catalyzed by iron salt at room temperature

[0061] According to the ratio of Example two, the water-soluble monomer N,N-dimethylaminoethyl methacrylate, initiator EBPA, catalyst tetraphenylporphyrin iron Fe(III)-TPP, ligand n-butyl bromide Ammonium chloride TBA-Br and UV photoinitiator TPO were added to the 5mL ampoule, then p-xylene (1.0 mL) and absolute ethanol (1.0 mL) were added to it, the tube was melted and sealed, and the ampoule was transferred to temperature Polymerization was carried out under a UV lamp (50 W) at room temperature with magnetic stirring. Break the tube after the scheduled polymerization time (4 h), and add pure water (1.0 mL) to induce the separation of the catalyst-dissolved p-xylene phase and the polymer-dissolved ethanol phase, and pipette the upper p-xylene layer For recycling, the remaining ethanol layer is dialyzed to obtain the desired polymer, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com