Starch modified total biology-based PBAT biodegradable plastic and preparation method thereof

A biodegradable plastic and starch modification technology, applied in the field of bioplastics, can solve the problems of consumption of petroleum resources, excessive carbon dioxide, etc., and achieve the effect of solving white pollution, reducing consumption, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 starch-modified PBAT biodegradable plastics

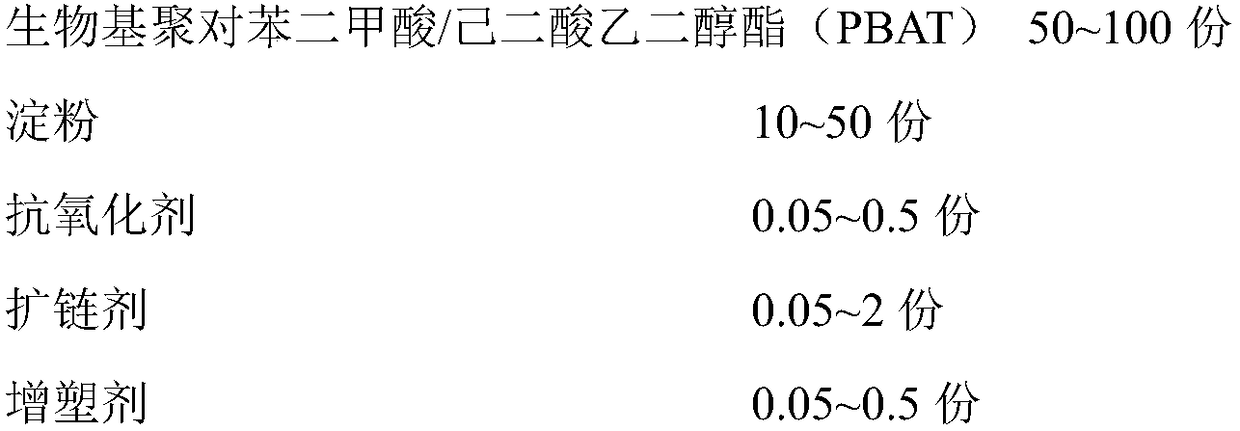

[0034] (1) The ratio (mass ratio) of raw materials is as follows:

[0035]

[0036] (2) According to the proportioning of above-mentioned raw materials, adopt the following steps to prepare:

[0037] (1) according to the method shown in authorized patent CN104031246A embodiment 4 synthetic all bio-based PBAT biodegradable resin;

[0038] (2) Dry a certain amount of bio-based PBAT and cornstarch at 25 degrees, 0-5000Pa for 2.0h;

[0039] (3) Add dried bio-based PBAT, starch, bisphenol A, dibutyl hydroxytoluene, triethyl citrate, epoxidized soybean oil, and zinc stearate into the high mixer and mix for 15 minutes;

[0040] (4) extruding and granulating the obtained mixed material through a twin-screw extruder to obtain starch-bio-based PBAT composite plastic particles;

[0041] (5) The composite plastic can be made into various fully bio-based biodegradable plastic film materials through f...

Embodiment 2

[0042] Embodiment 2 Preparation of starch-modified bio-based PBAT biodegradable plastics

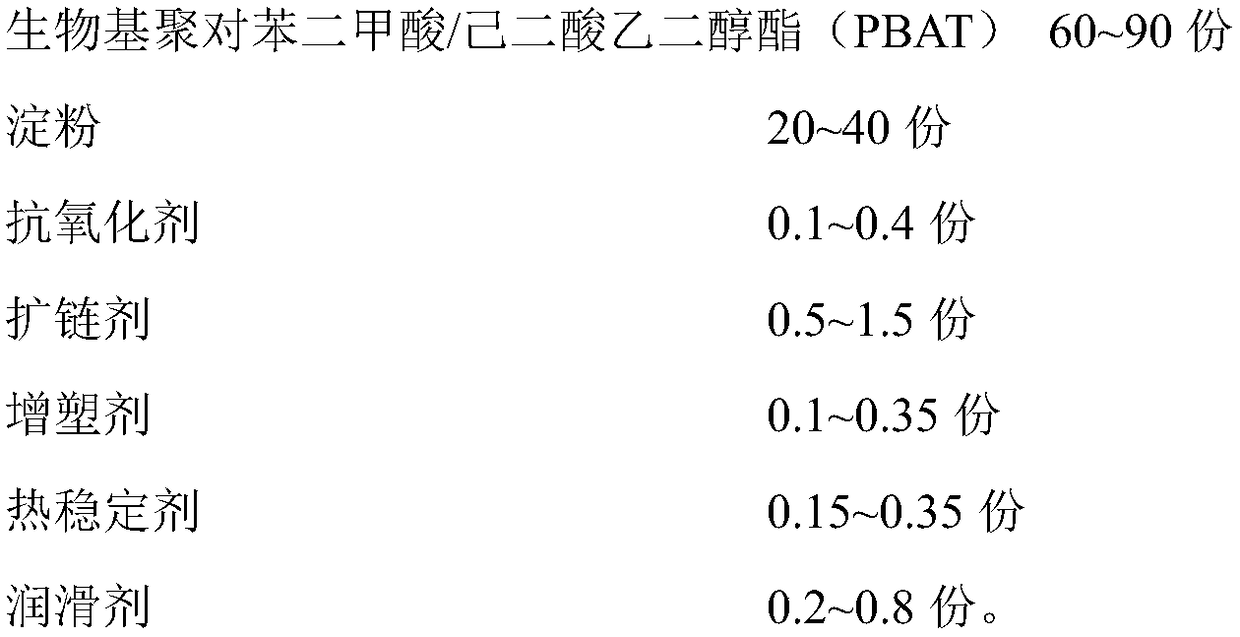

[0043] (1) The ratio (mass ratio) of raw materials is as follows:

[0044]

[0045] (2) According to the proportioning of above-mentioned raw materials, adopt the following steps to prepare:

[0046] (1) according to the method shown in authorized patent CN104031246A embodiment 4 synthetic all bio-based PBAT biodegradable resin;

[0047] (2) Dry a certain amount of bio-based PBAT and tapioca starch at 25 degrees, 0-5000Pa for 3 hours;

[0048] (3) Add dry bio-based PBAT, starch, acetyl tri-n-butyl citrate, resorcinol dihydroxyethyl ether, butyl hydroquinone, epoxidized soybean oil, stearic acid into the high mixer Calcium mix for 20 minutes;

[0049] (4) extruding and granulating the obtained mixed material through a twin-screw extruder to obtain starch-PBAT composite plastic particles;

[0050] (5) The composite plastic can be made into various fully bio-based biodegradable plast...

Embodiment 3

[0051] Embodiment 3 Preparation of starch-modified bio-based PBAT biodegradable plastics

[0052] (1) The ratio (mass ratio) of raw materials is as follows:

[0053]

[0054] (2) According to the proportioning of above-mentioned raw materials, adopt the following steps to prepare:

[0055] (1) according to the method shown in authorized patent CN104031246A embodiment 4 synthetic all bio-based PBAT biodegradable resin;

[0056] (2) Dry a certain amount of bio-based PBAT and cornstarch at 25 degrees and 0-5000 Pa for 3 hours;

[0057] (3) Add dried bio-based PBAT, starch, maleic anhydride, glycerol triacetate, butyl hydrodiphenol, 1,4-butanediol, and zinc stearate into the high mixer and mix for 25 minutes ;

[0058] (4) extruding and granulating the obtained mixed material through a twin-screw extruder to obtain starch-PBAT composite plastic pellets;

[0059] (5) The composite plastic can be made into various fully bio-based biodegradable plastic film materials through fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com