Nanometer composite fiber membrane and preparation method thereof

A technology of nanocomposite fibers and nanofiber membranes, applied in fiber types, fiber treatment, chemical instruments and methods, etc., can solve problems such as shedding and MOF particle loss, and achieve high production efficiency, improved adhesion, and no environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

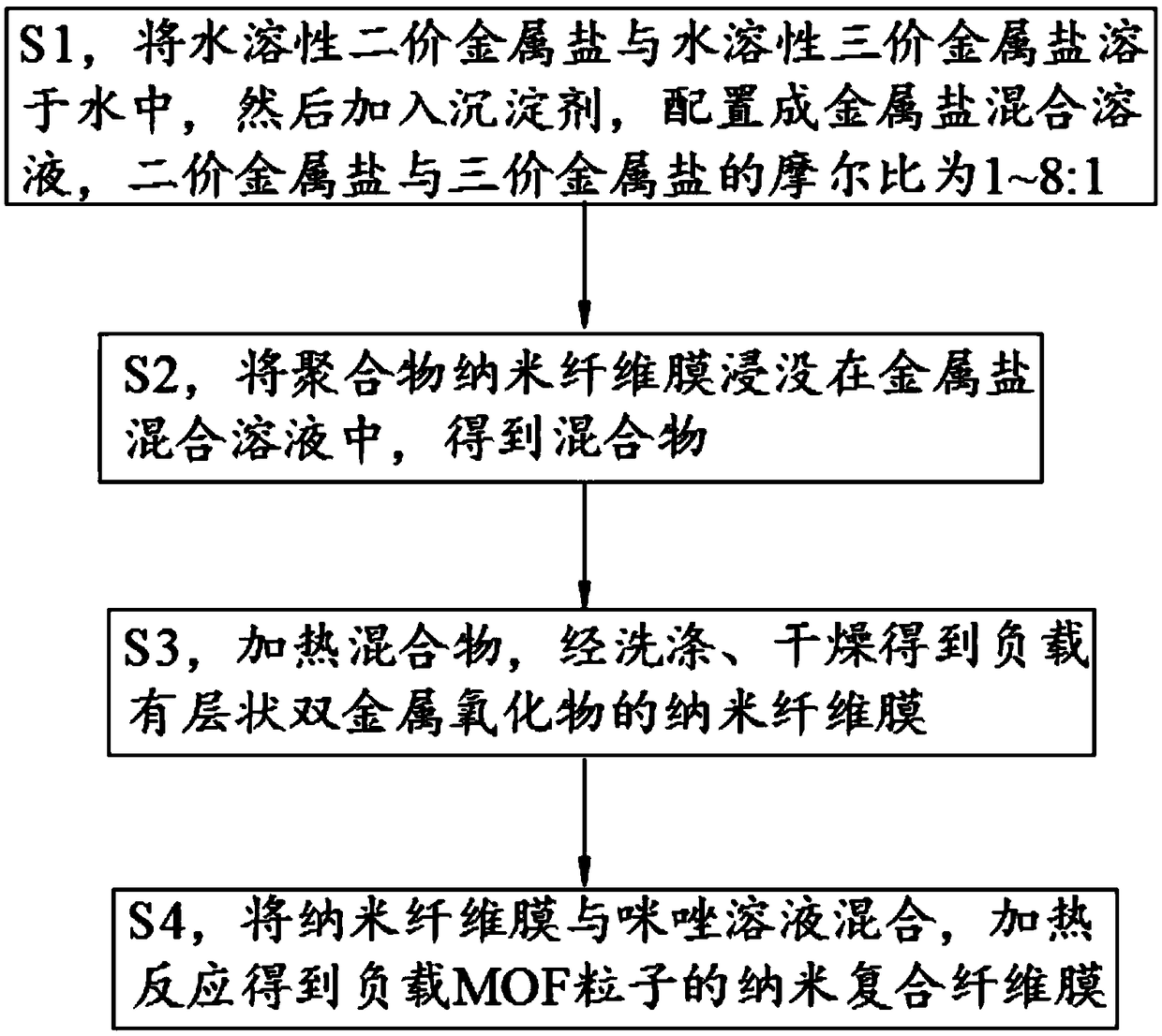

[0019] A method for preparing a nanocomposite fiber membrane provided by an embodiment of the present invention comprises the following steps:

[0020] S1, dissolving the water-soluble divalent metal salt and the water-soluble trivalent metal salt in water, and then adding a precipitant to configure a metal salt mixed solution, wherein the molar ratio of the divalent metal salt to the trivalent metal salt 1~8:1;

[0021] S2, immersing the polymer nanofiber membrane in the metal salt mixed solution to obtain a mixture;

[0022] S3, heating the mixture, washing and drying to obtain a nanofibrous membrane loaded with layered double metal oxide;

[0023] S4, mixing the nanofiber membrane with the imidazole solution, heating and reacting to obtain a nanocomposite fiber membrane loaded with MOF particles.

[0024] In step S1, preferably, the molar ratio of the divalent metal salt to the trivalent metal salt is 2-4:1, more preferably, the molar ratio of the divalent metal salt to t...

Embodiment 1

[0040] A nanocomposite fiber membrane provided in this embodiment is prepared according to the following steps:

[0041] a. Add 2.91g (0.01mol) cobalt nitrate hexahydrate, 1.87g (0.005mol) aluminum nitrate nonahydrate, 2g urea and 150mL deionized water to the PTFE lining of the hydrothermal reactor; stir and dissolve to obtain metal Salt mixed solution;

[0042] b. Weigh 2g polyacrylonitrile nanofiber membrane, and soak it in the metal salt mixed aqueous solution in a for 0.5h;

[0043] c. Lock the hydrothermal reactor and place it at 120°C to react for 12 hours; after the reactor is cooled to room temperature, take out the polyacrylonitrile nanofiber membrane, wash with water and dry to obtain Co 3 Al-LDH loaded nanofibrous membrane;

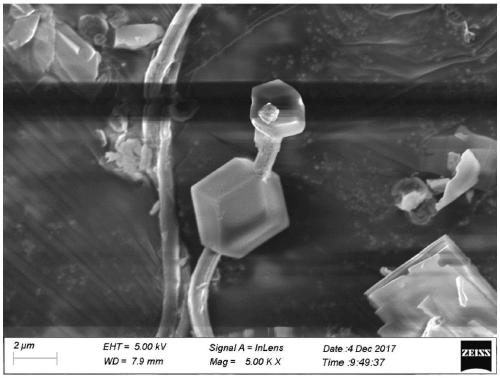

[0044] d. Add 1g of Co to the PTFE lining of the hydrothermal reactor 3 Al-LDH-loaded nanofiber membrane, 0.5g 2-methylimidazole and 50mL methanol; lock the hydrothermal reactor and place it at 100°C for 12h; wait for the reactor to cool dow...

Embodiment 2

[0047] A nanocomposite fiber membrane provided in this embodiment is prepared according to the following steps:.

[0048] a. Add 2.97g (0.01mol) zinc nitrate hexahydrate, 1.87g (0.005mol) aluminum nitrate nonahydrate, 2g urea and 150mL deionized water to the PTFE lining of the hydrothermal reactor; stir and dissolve to obtain metal Salt mixed solution;

[0049] b. Weigh 2g polyimide nanofiber membrane, and soak it in a metal salt mixed aqueous solution for 0.5h;

[0050] c. Lock the hydrothermal reactor and place it in an oven at 110°C to react for 12 hours; after the reactor cools down to room temperature, take out the polyacrylonitrile nanofiber membrane, wash with water and dry to obtain ZnAl-LDH-loaded nanofiber Fiber membrane;

[0051] d: Add 1g ZnAl-LDH loaded nanofiber membrane, 0.5g 2-methylimidazole and 50mL methanol to the PTFE lining of the hydrothermal reactor; lock the hydrothermal reactor and place it at 100°C Reaction in an oven for 12 hours; after the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com