Dimerization surfactant wormlike micelle and preparation method thereof

A technology of worm-like micelles and surfactants, which is applied in the field of dimeric surfactant worm-like micelles and its preparation, which can solve the problems of complex molecular structure, difficult to obtain raw materials, and long synthetic routes, and achieve high biodegradability , excellent viscoelastic performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Preparation of dimeric surfactant worm-like micelles

[0045] Mix 11.8g, 0.2mol (ethanol solution) of trimethylamine and 18.6g, 0.1mol of 1,2-dibromoethane at a ratio of 2:1, and a substitution reaction occurs at 25°C for 3.5 hours to generate N1, N1, N1, N2, N2, N2-hexamethylethane-1,2-diammonium, then sodium oleate 0.1824g, 0.0006mol and the synthesized N1, N1, N1, N2, N2, N2-hexamethylethane Alkane-1,2-diammonium 0.0912g, 0.0003mol mixed according to the ratio of 2:1, then add 1.73g of ultrapure water, through electrostatic attraction at 25°C, to construct sodium oleate and N1, N1, N1, N2, N2 , N2-hexamethylethane-1,2-diammonium type dimeric surfactant worm-like micelles.

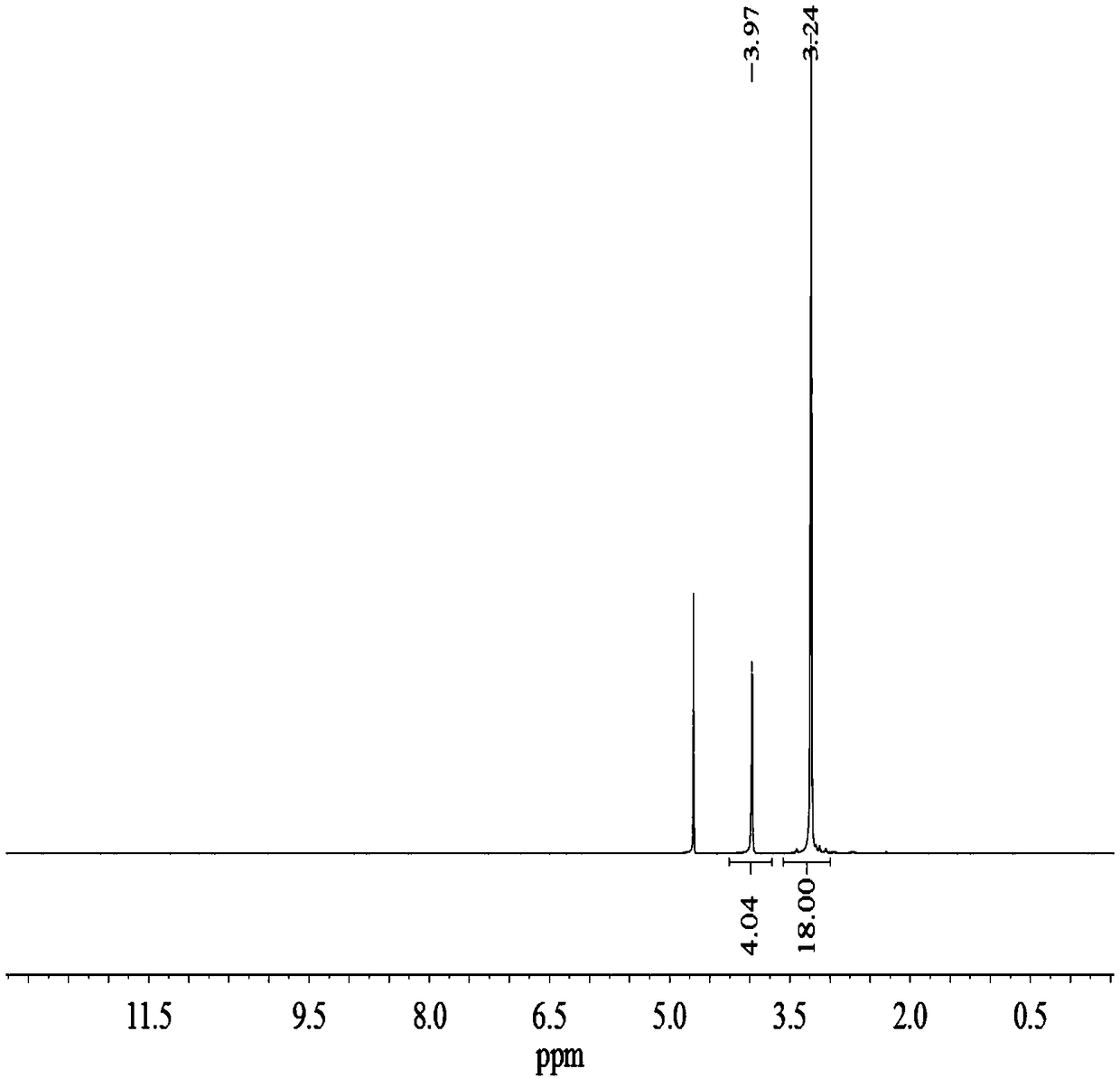

[0046] The synthesized N1, N1, N1, N2, N2, N2-hexamethylethane-1,2-diammonium obtained nuclear magnetic resonance 1HNMR spectrum, such as figure 1 .

[0047] according tofigure 1 NMR spectrum analysis, the final product N1, N1, N1, N2, N2, N2-hexamethylethane-1,2-diammonium was disso...

Embodiment 2

[0049] Embodiment 2: the impact of sodium oleate / dimer quaternary ammonium salt concentration on the zero-shear viscosity of surfactant of the present invention

[0050] Prepare 6 groups of samples with concentrations of 2ml in each group. The ratios of sodium oleate concentration to dimer salt concentration in the sample are 300mmol: 150mmol, 250mmol: 125mmol, 200mmol: 100mmol, 150mmol: 75mmol, 100mmol: 50mmol, 50mmol: 25mmol.

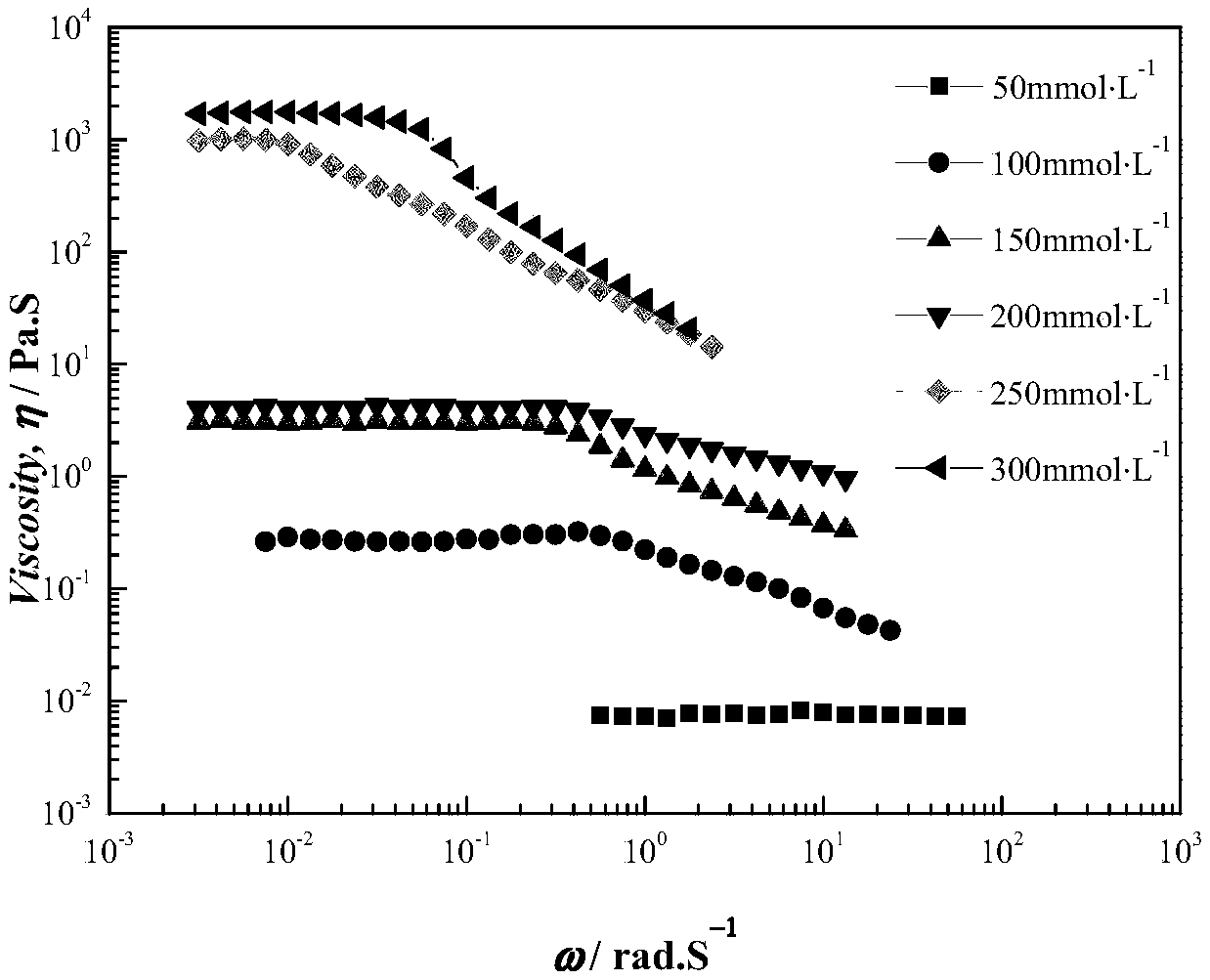

[0051] The obtained worm-like micelles were subjected to viscoelasticity measurements, and the results were as follows figure 2 .

[0052] It can be seen from the results that when the concentration of sodium oleate / C2 dimer quaternary ammonium salt type gemini surfactant is 100mM: 50mM, as the shear rate increases, the solution appears shear thinning phenomenon, which is the formation of worm-like micelles. A feature of the system; when the concentration of sodium oleate / C2 dimer salt increases to 300mM: 150mM, the viscosity of the system can rise ...

Embodiment 3

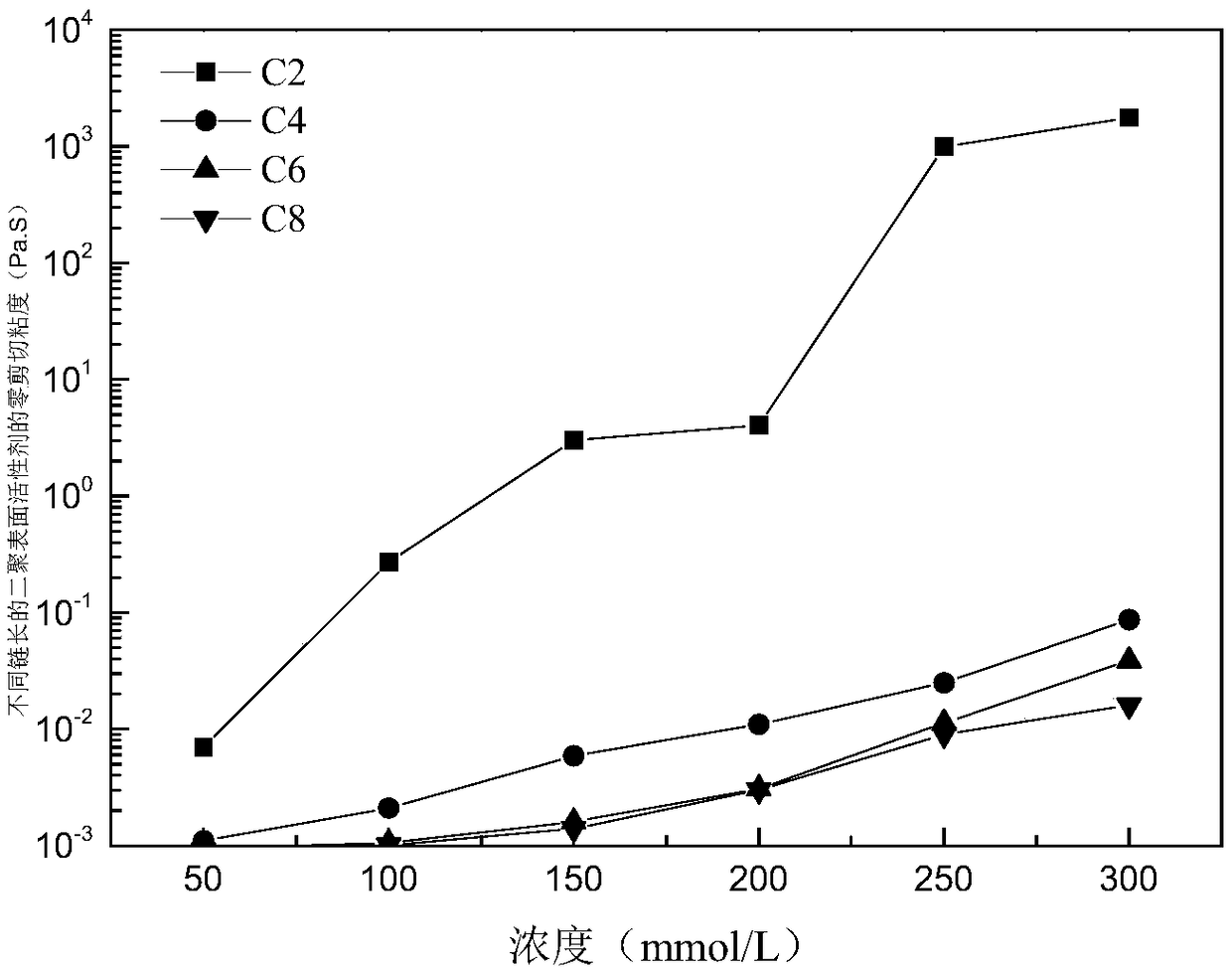

[0055] Embodiment 3: The effect of dimer salt connection length on the aggregation ability / viscoelastic properties / zero shear viscosity of the surfactant of the present invention

[0056] Trimethylamine 11.8g, 0.2mol (ethanol solution) was mixed with 1,4-dibromobutane 18.7g, 0.1mol, 1,6-dibromohexane 18.8g, 0.1mol, 1,8-dibromooctane 18.9g, 0.1mol were mixed according to the ratio of 2:1, substitution reaction occurred at 25°C, reacted for 3.5h, and N1, N1, N1, N2, N2, N2-hexamethylethane-1,2-diammonium, N1, N1, N1, N4, N4, N4-hexamethylbutane-1,4-diamine, N1, N1, N1, N6, N6, N6-hexamethylhexane-1,6-diamine, N1, N1, N1, N8, N8, N8-hexamethyloctane-1,8-diammonium;

[0057] Then 0.1824g, 0.0006mol of sodium oleate and the synthesized N1, N1, N1, N2, N2, N2-hexamethylethane-1,2-diammonium 0.0912g, 0.0003mol, N1, N1, N1, N4 , N4, N4-hexamethylbutane-1,4-diamine 0.0922g, 0.0003mol, N1, N1, N1, N6, N6, N6-hexamethylhexane-1,6-diamine 0.0942g, 0.0003mol, N1, N1, N1, N8, N8, N8-hexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com