Environment-friendly waterborne coating and preparation method thereof

A water-based coating, environmental protection technology, applied in the direction of coating, etc., can solve the problems of low hardness, wear resistance and other physical indicators, low equipment dependence, general performance, etc., to achieve low production cost and low equipment dependence , excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

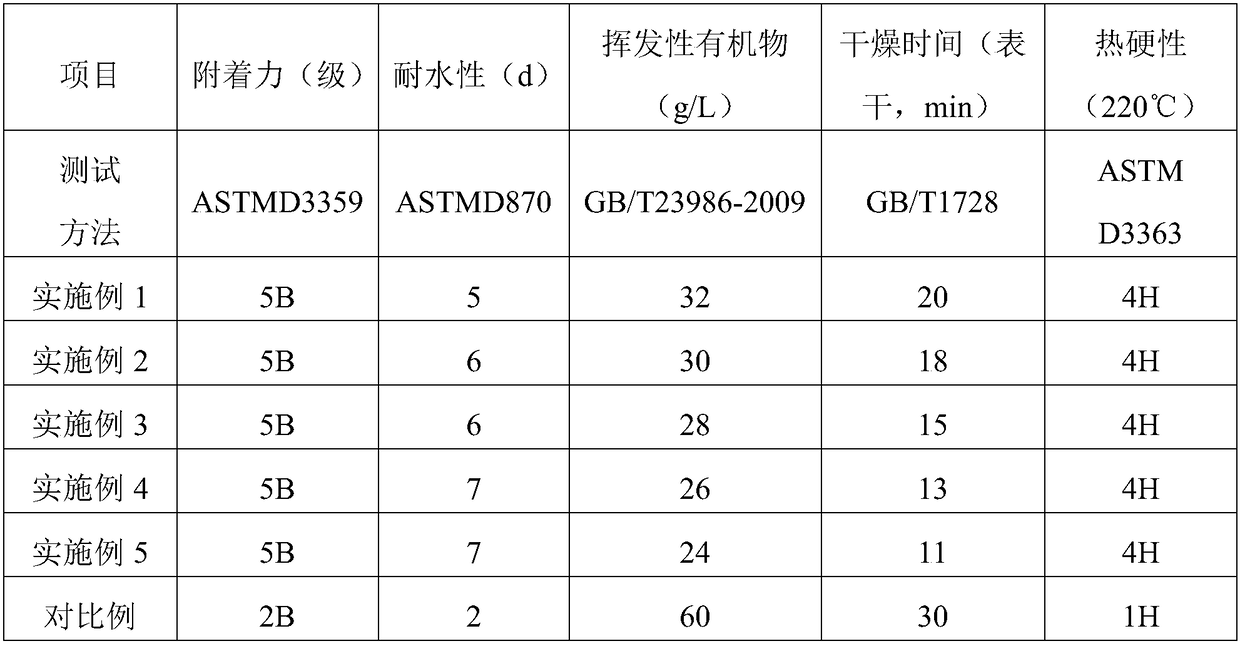

Examples

Embodiment 1

[0030] An environmentally friendly water-based paint, which is made of the following components in parts by weight: 45 parts of modified polyethylene glycol methacrylate film-forming polymers, 20 parts of pyrrolidone-based ionic copolymers, and 1 part of polyacrylate leveling agent parts, 10 parts of nano-titanium dioxide, 2 parts of tributyl phosphate, and 20 parts of water.

[0031] The preparation method of described modified polyethylene glycol methacrylate film-forming polymer comprises the steps:

[0032] 1) Under a nitrogen atmosphere, dissolve 28.5 g of polyethylene glycol methacrylate and 10 g of hexacyano-1,3-butadiene in 100 g of N,N-dimethylformamide to form a solution, and then dissolve the solution Add it into a three-neck flask equipped with a reflux condenser and an electric stirrer, reflux and stir at 110°C for 4 hours, and then precipitate it in n-hexane, filter it, and bake it in a vacuum oven at 70°C for 18 hours to obtain Modified polyethylene glycol meth...

Embodiment 2

[0038] An environmentally friendly water-based paint, made of the following components in parts by weight: 48 parts of modified polyethylene glycol methacrylate film-forming polymers, 23 parts of pyrrolidone ionic copolymers, cellulose acetate leveling agent 2 parts, 12 parts of nano titanium dioxide, 31003 parts of defoamer Deqian, 23 parts of water.

[0039] The preparation method of described modified polyethylene glycol methacrylate film-forming polymer comprises the steps:

[0040] 1) Under a helium atmosphere, dissolve 28.5g of polyethylene glycol methacrylate and 10g of hexacyano-1,3-butadiene in 110g of N-methylpyrrolidone to form a solution, and then add the solution to the container In a three-neck flask with a reflux condenser and an electric stirrer, reflux and stir at 113°C for 4.5 hours, then precipitate in n-hexane, filter and then bake in a vacuum oven at 73°C for 20 hours to obtain the modified polymer Ethylene glycol methacrylate.

[0041] 2) Mix 14.7 g of ...

Embodiment 3

[0046] An environmentally friendly water-based paint, made of the following components in parts by weight: 50 parts of modified polyethylene glycol methacrylate film-forming polymers, 25 parts of pyrrolidone-based ionic copolymers, polyvinyl butyral fluid 3 parts of leveling agent, 13 parts of nano-titanium dioxide, 3 parts of defoamer BYK0888, 25 parts of water.

[0047] The preparation method of described modified polyethylene glycol methacrylate film-forming polymer comprises the steps:

[0048] 1) Under a neon gas atmosphere, dissolve 28.5g of polyethylene glycol methacrylate and 10g of hexacyano-1,3-butadiene in 125g of dimethyl sulfoxide to form a solution, and then add the solution to the In a three-neck flask with a reflux condenser and an electric stirrer, reflux and stir at 116°C for 5 hours, then precipitate in n-hexane, filter and then bake in a vacuum oven at 76°C for 22 hours to obtain modified polyethylene Diol methacrylate;

[0049] 2) Mix 14.7 g of modified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com