Weather-resistant polymer modified asphalt cement waterproof paint and preparation method thereof

A technology of modified asphalt and waterproof coatings, applied in the field of coatings, which can solve the problems of low durability and mechanical strength of coatings, inability to use waterproof roofs, short service life, etc., and achieve the effects of improving waterproofness, low price, and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

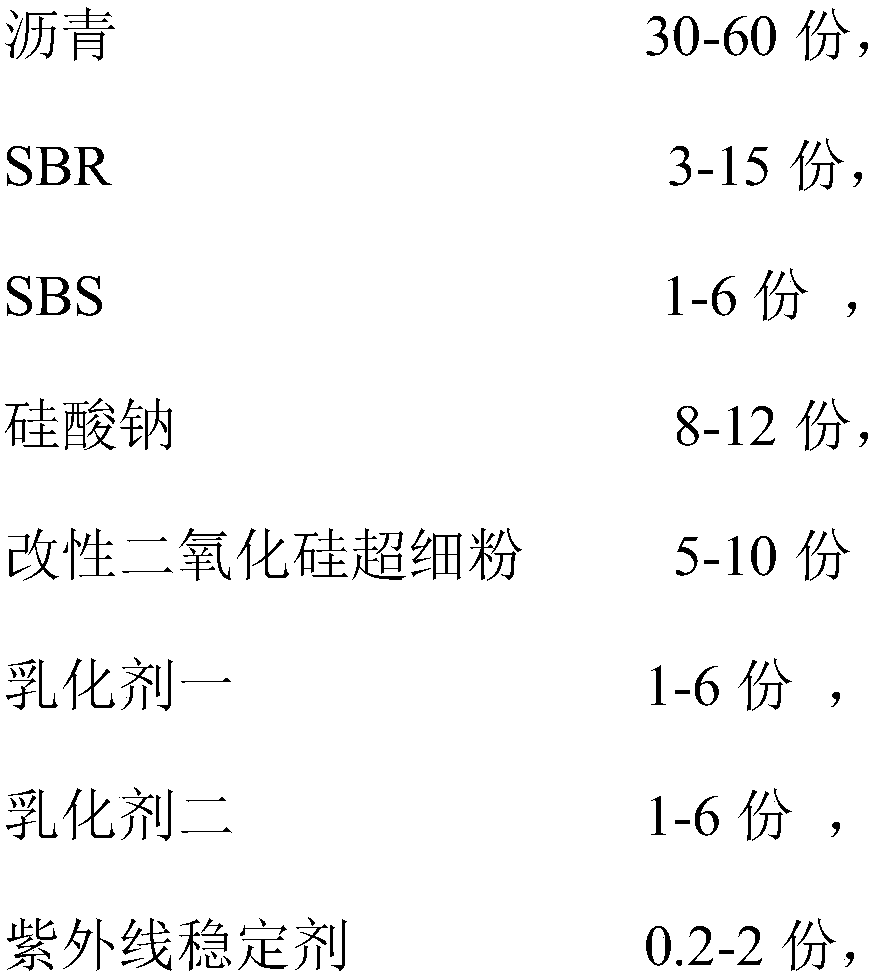

[0039] The weather-resistant polymer modified asphalt cement waterproof coating in this example is composed of A component and B component. When in use, the liquid material and the powder material are mixed according to 1:1, wherein, A component, Component B is made from the raw materials of the following parts by weight respectively,

[0040] A component:

[0041]

[0042]

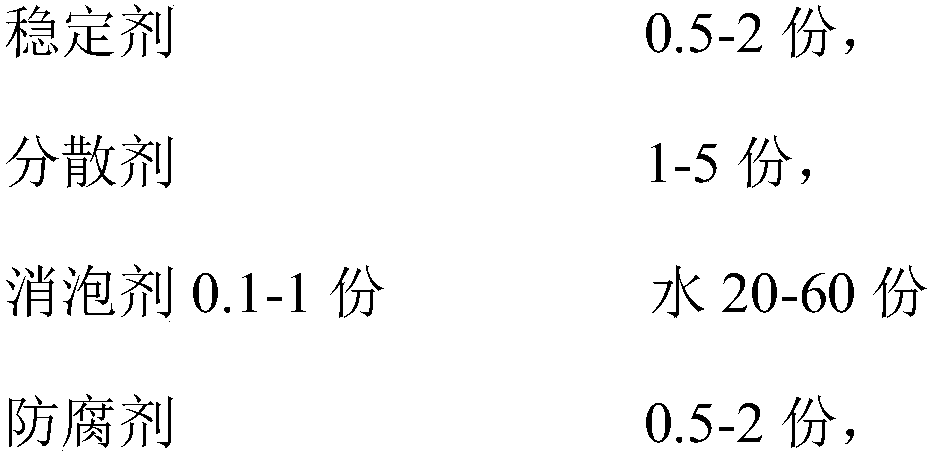

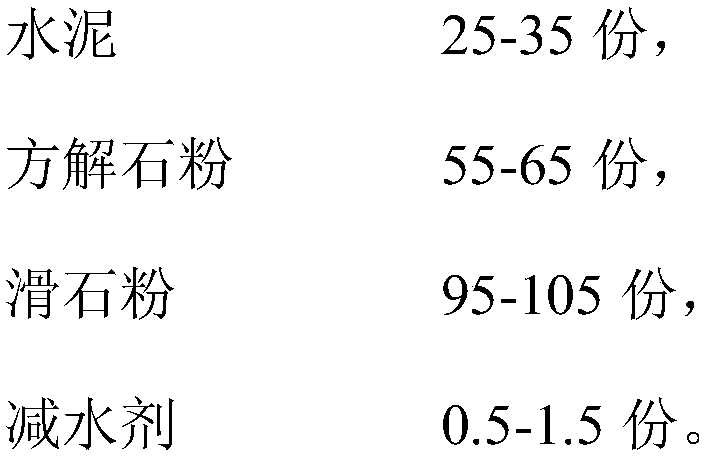

[0043] B component:

[0044]

[0045] In this implementation, as a preferred embodiment: the asphalt is selected from 200# asphalt, and the modified silica ultrafine powder is silane coupling KH-550 modified silica ultrafine powder, and its particle size It is nano-scale; the first emulsifier is hexadecylamine, and the second emulsifier is coconut acid diethanolamide. The ultraviolet stabilizer is a hindered amine stabilizer. The stabilizer is tartaric acid, the dispersant is polyacrylate, the defoamer is emulsified silicone oil, the preservative is isothiazolinone derivatives, and the water r...

Embodiment 2

[0055] The weather-resistant polymer modified asphalt cement waterproof coating described in this example is composed of component A and component B. When in use, the liquid material and the powder material are mixed according to 1:1.2, wherein, component A, Component B is made from the raw materials of the following parts by weight respectively,

[0056] A component:

[0057]

[0058]

[0059] B component:

[0060]

[0061] In this implementation, the so-called preferred implementation mode: the asphalt is 200# asphalt; the modified silica ultrafine powder is silane coupling KH-550 modified silica ultrafine powder, and its particle size is nanometer. The first emulsifier is coconut oil amine; the second emulsifier is coconut acid diethanolamide; 5'-methylphenyl)-5-chlorobenzotriazole; The stabilizer is acetic acid; The dispersant is polyethylene glycol ester and sodium lauryl sulfate; The defoamer is high Carbon alcohol fatty acid ester complex; the preservative i...

Embodiment 3

[0070] The weather-resistant polymer modified asphalt cement waterproof coating in this example is composed of A component and B component. When in use, the liquid material and the powder material are mixed according to 1:0.8, wherein, A component, Component B is made from the raw materials of the following parts by weight respectively,

[0071] A component:

[0072]

[0073]

[0074] B component:

[0075]

[0076] In this implementation, as a preferred embodiment: the asphalt is selected from 200# asphalt, and the modified silica ultrafine powder is silane coupling KH-550 modified silica ultrafine powder, and its particle size to the nanoscale. Described emulsifier one 1-aminoethyl-2-heptadecyl imidazoline-2 hydrochloride, described emulsifier two is polyoxyethylene sorbitan monooleate; Described ultraviolet stabilizer is 2-( 2'-hydroxyl-5'-methylphenyl) benzotriazole; The stabilizer is a nitrate; The dispersant is a fatty acid; The defoamer is a higher alcohol fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com