Solid waste pyrolyzing system coupling with direct combustion of high-temperature pyrolysis gas

A solid waste, high-temperature pyrolysis technology, applied in educts, biofuels, indirect heating and dry distillation, etc., can solve the problems of secondary pollution of equipment pyrolysis tar, low energy recovery rate of solid waste, and clogging of pyrolysis tar. , to achieve significant energy-saving benefits, reduced volume, and reduced investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

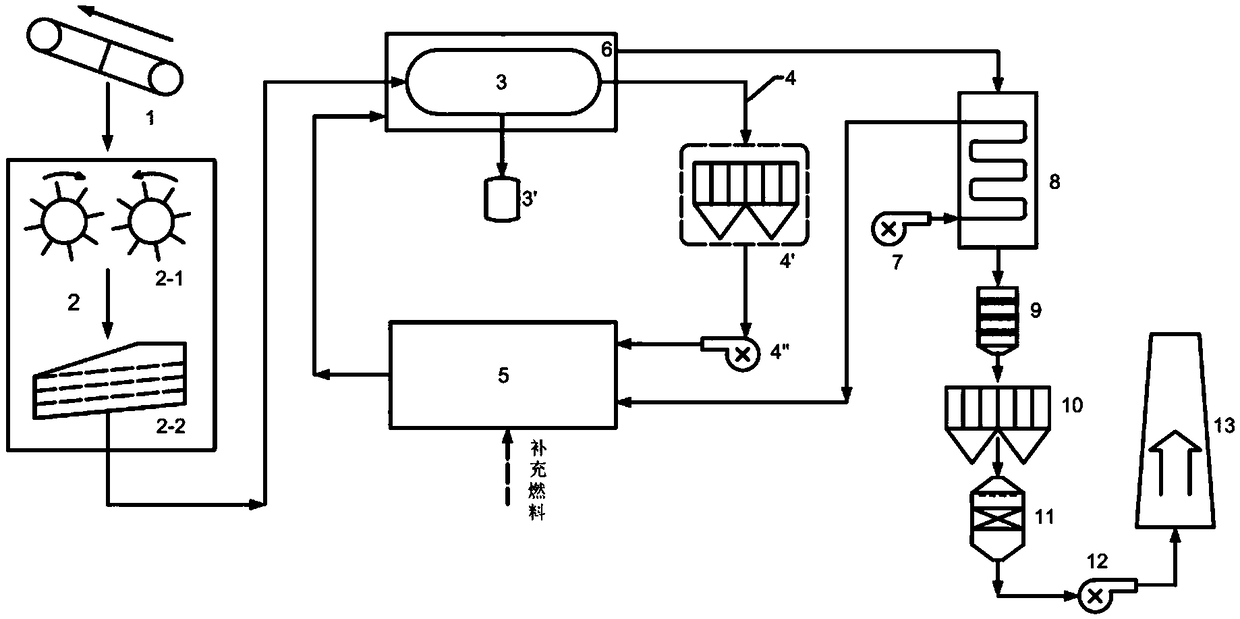

[0014] refer to figure 1 , a solid waste pyrolysis system coupled with direct combustion of high-temperature pyrolysis gas, including a solid waste conveying system 1, a pretreatment system 2 (including a crushing system 2-1, a sorting system 2-2), and a pyrolysis furnace 3 , high-temperature pipeline 4, high-temperature dust collector 4', synthesis gas compressor 4", combustion system 5, heating furnace 6, blower 7, air preheater 8, flue gas purification treatment system (including off-stock tower 9, dust collector 10, Desulfurization tower 11, induced draft fan 12, chimney 13).

[0015] In the system, the transportation system 1 continuously sends the solid waste to the pretreatment system 2;

[0016] The pretreatment system 2 performs pretreatment such as crushing and sorting on solid waste. The role of crushing system 2-1 is to reduce the size of plastic, rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com