Preparation method of perovskite quantum dot array

A perovskite and quantum dot technology, applied in radiation control devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem that perovskite quantum dot materials cannot meet the practical application requirements of optoelectronic devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0099] Embodiments of the present invention provide a method for preparing a perovskite quantum dot pattern, comprising:

[0100] Prepare templates required for patterning perovskite quantum dots;

[0101] transferring the perovskite quantum dot precursor solution onto the template;

[0102] Place the template attached with the perovskite quantum dot precursor solution in a dry box to complete the in-situ generation and patterning process of perovskite quantum dots;

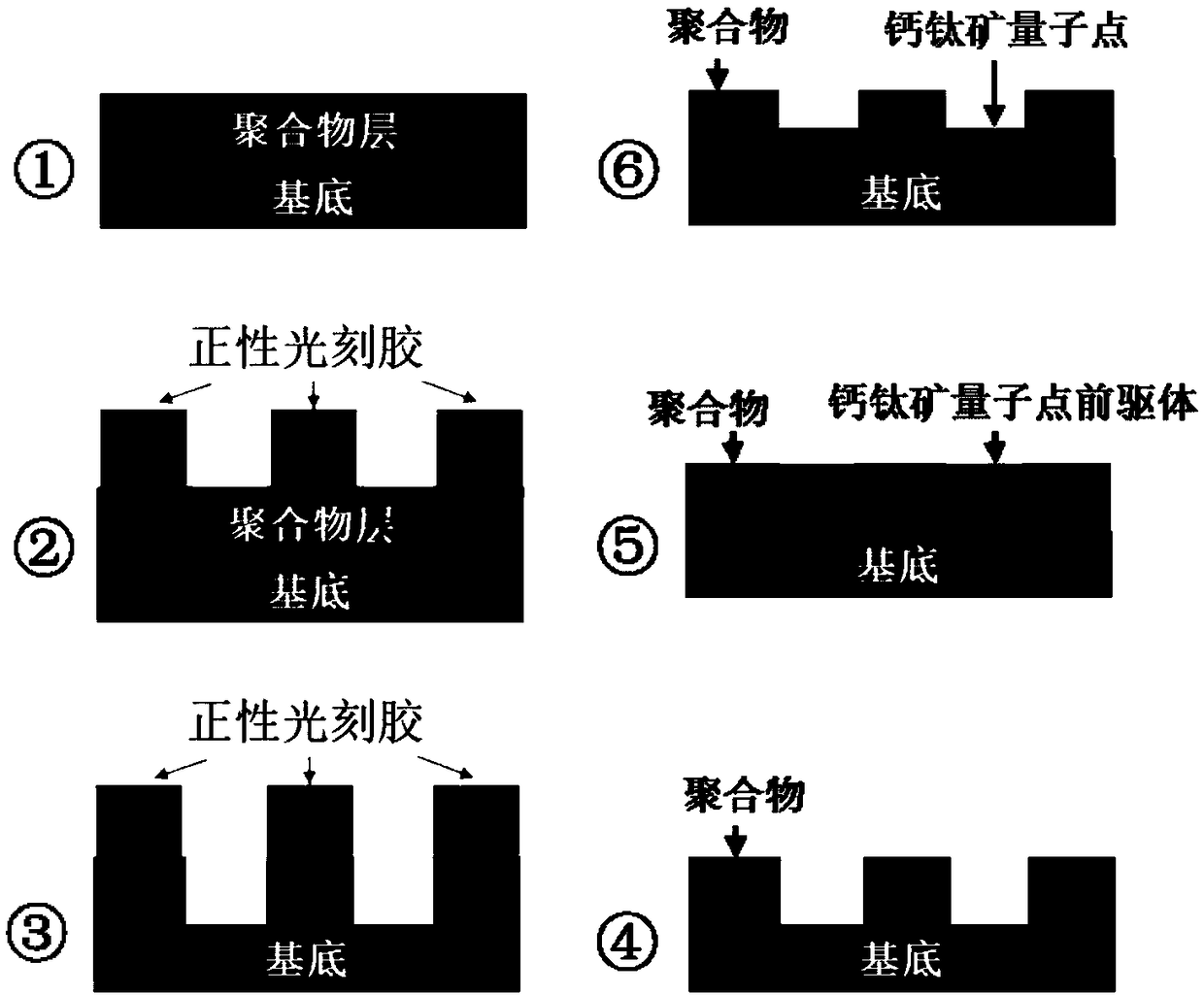

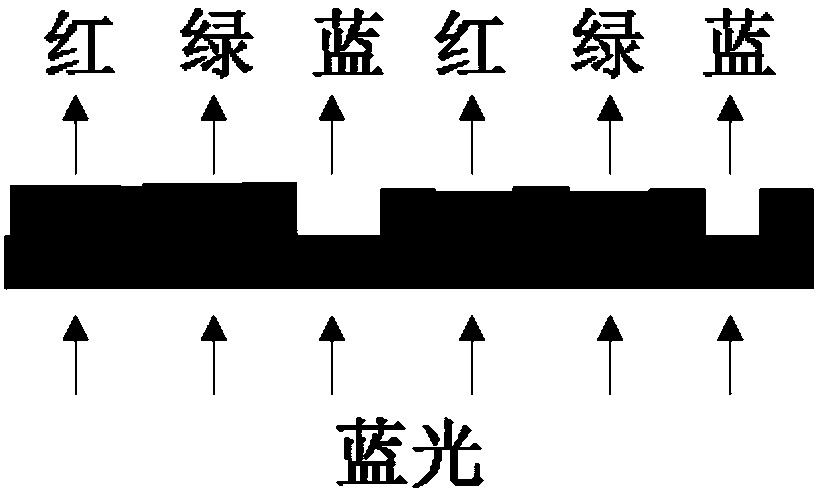

[0103] The preparation of templates required for patterning perovskite quantum dots involves three stages: as figure 1 As shown in (1-3), the first stage is to prepare a polymer film layer on the substrate, the second stage is to use photoresist to prepare the required pattern on the polymer film layer, and the third stage is to use RIE etching After the part of the polymer layer not protected by the photoresist is removed by etching, the remaining photoresist is cleaned to obtain a polymer template with groov...

Embodiment 1

[0120] Embodiment 1 perovskite quantum dot array (pattern)

[0121] Select a 10cm*10cm Corning 0.7t glass substrate as the substrate, and drop 10wt% poly-TPD / chlorobenzene solution on the substrate. A poly-TPD layer with a wet film thickness of 3um was obtained by three-stage spin coating (200rmp 1min; 500rpm 1min; 800rpm 2min). After drying in a vacuum oven at 60°C for 30 minutes, a 1um poly-TPD polymer layer was obtained.

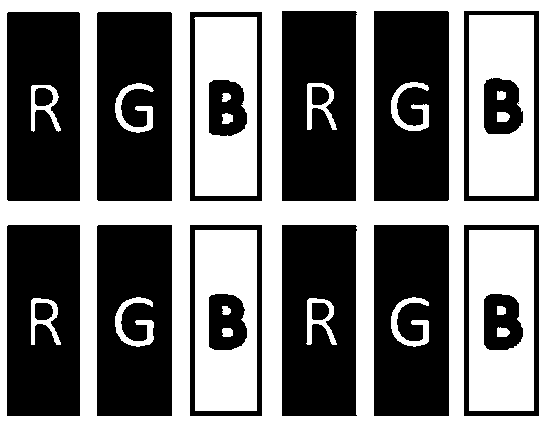

[0122] The positive photoresist is spin-coated on the surface of the polymer layer at 200rpm for 1min and 500rpm for 3min to obtain a photoresist layer with a thickness of 2.5um. Pass through the BG-401A exposure machine of Zhongdian 45 Institute to let the light pass through the mask The upper hollow part (30*100 micron pixel array) is irradiated to the corresponding area of the photoresist, and is dissolved by tetramethylammonium hydroxide (TMAH) developer in the subsequent development process to form the required pattern. Use RIE-8101 reactive ion ...

Embodiment 2

[0124] Embodiment 2 perovskite quantum dot array (pattern)

[0125] A 10cm*10cm Corning 0.7t glass substrate was selected as the substrate, and the PI coating solution of DuPont RC5044 was coated on the substrate by three-stage spin coating (200rmp 1min; 500rpm 1min; 800rpm 2min) to obtain a PI layer with a wet film thickness of 2um. After drying in a vacuum oven at 120 degrees Celsius for 60 minutes, a 1.5um PI polymer layer was obtained.

[0126] The positive photoresist is spin-coated on the surface of the polymer layer at 200rpm for 1min and 500rpm for 3min to obtain a photoresist layer with a thickness of 2.5um. Pass through the BG-401A exposure machine of Zhongdian 45 Institute to let the light pass through the mask The upper hollow part (30*100 micron pixel array) is irradiated to the corresponding area of the photoresist, and is dissolved by tetramethylammonium hydroxide (TMAH) developer in the subsequent development process to form the required pattern. Use RIE-810...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com