Preparation method of rodlike porous graphite-phase carbon nitride photocatalytic material

A technology based on carbon nitride light and porous graphite, which is applied in the field of photocatalysis, can solve problems such as the need to improve absorption in the visible light region, shorten the migration distance of electrons and holes, and reduce the lifetime of carriers, so as to achieve good application prospects and improve photocatalysis. Catalytic performance, effect of reducing recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

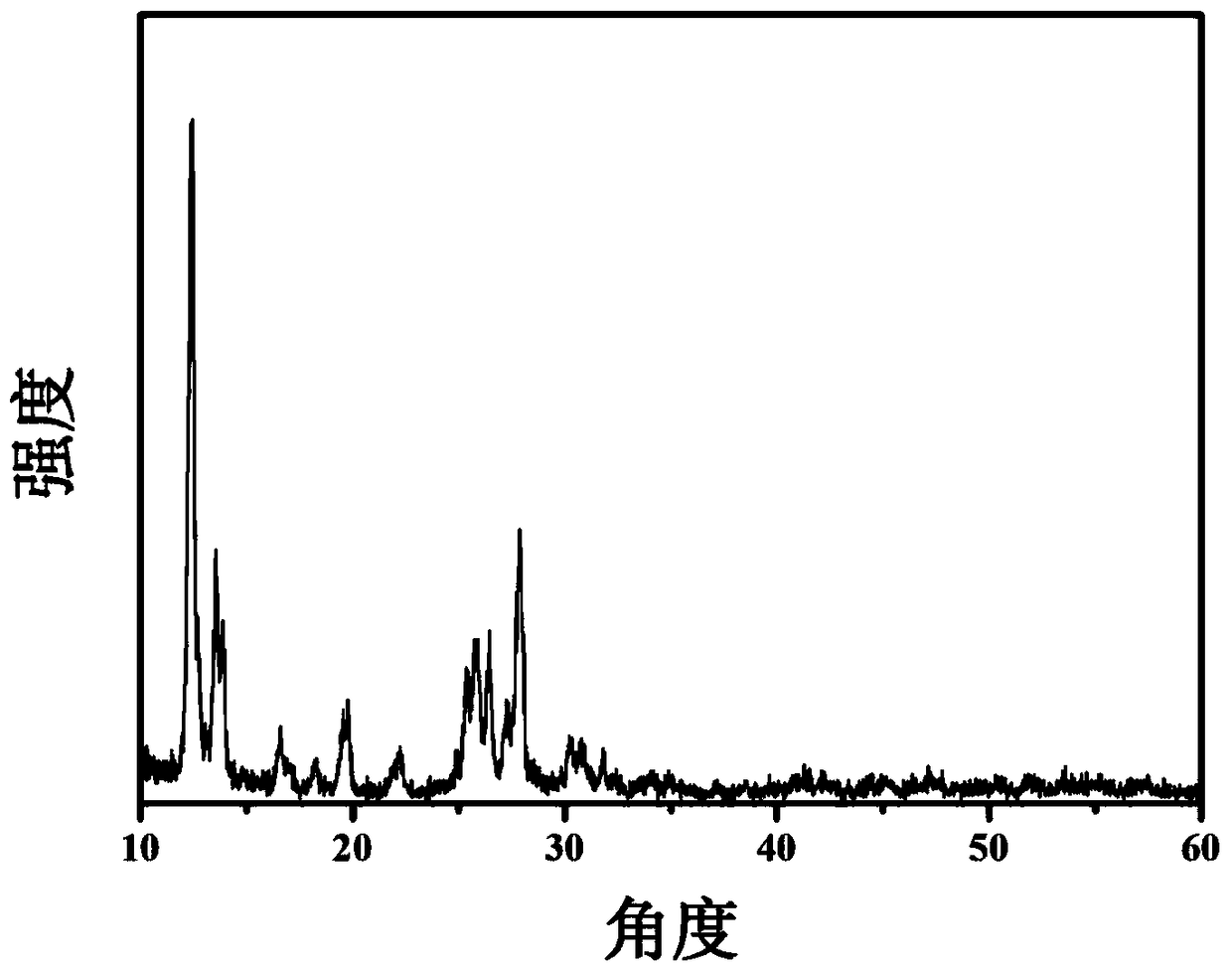

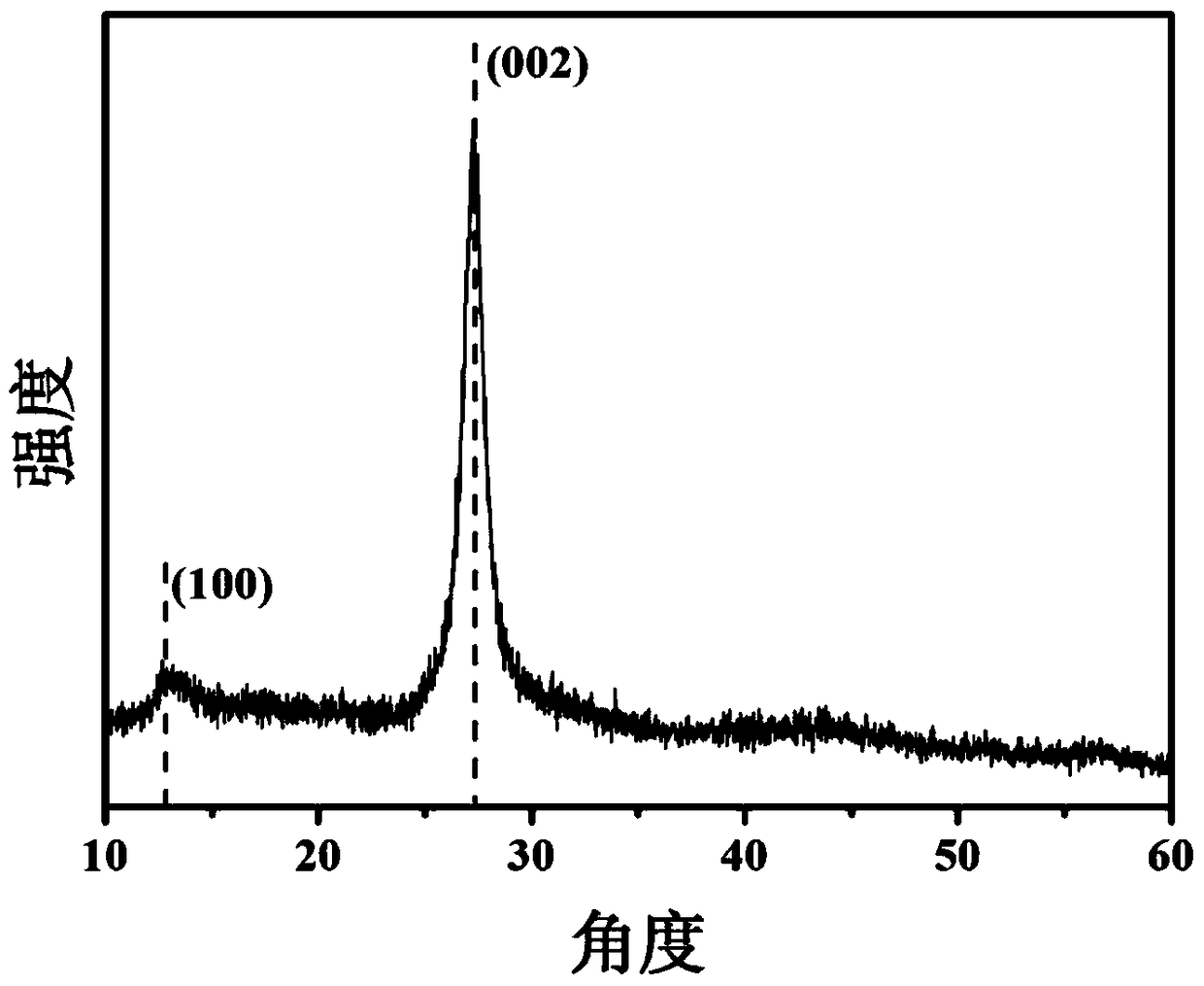

Embodiment 1

[0022] Put 30 grams of melamine into a 50ml crucible with a lid and transfer it to a box furnace, heat it to 430°C at a rate of 5°C / min in a static air atmosphere, keep it warm for 4h, and put the powder cooled with the furnace For further grinding, put 1 g of the ground powder into a beaker and add 30 ml of deionized water. After ultrasonication for 15 minutes, the sample was washed with deionized water several times, and finally washed with ethanol, centrifuged at 4000 rpm for 15 minutes, and the obtained sample was dried overnight and dried. Grind to obtain the intermediate rod-shaped melem, then put 1g of the intermediate into a crucible with a lid and transfer it to a box furnace, heat it to 550°C at a heating rate of 5°C / min in an air atmosphere, and keep it warm 4h, and cooled with the furnace, the resulting product was collected.

Embodiment 2

[0024] Put 30 grams of melamine into a 50ml crucible with a lid and then transfer it to a box furnace, heat it to 430°C at a rate of 5°C / min in an Ar gas atmosphere, keep it warm for 4h, and further cool the powder with the furnace Grinding, put 1g of ground powder into a beaker and add 30ml of deionized water, after ultrasonication for 15min, wash the sample with deionized water several times, finally wash with ethanol, centrifuge at 4000rpm for 15min, dry the obtained sample overnight, that is The intermediate rod-shaped melem was obtained, and then 1 g of the intermediate was put into a crucible with a lid and then transferred to a box furnace, heated to 550 °C at a heating rate of 5 °C / min in an Ar gas atmosphere, and kept for 4 hours. And with furnace cooling, the resulting product was collected.

Embodiment 3

[0026] Put 30 grams of melamine into a 50ml crucible with a lid and transfer it to a box furnace, heat it to 430°C at a rate of 5°C / min in a static air atmosphere, keep it warm for 4h, and put the powder cooled with the furnace For further grinding, put 1g of the ground powder into a beaker and add 30ml of deionized water. After ultrasonication for 30min, the sample was washed with deionized water several times, and finally washed with ethanol, centrifuged at 4000rpm for 15min, and the obtained sample was dried overnight. That is, the intermediate rod-shaped melem was obtained, and then 1 g of the intermediate was put into a crucible with a lid and then transferred to a box furnace, heated to 550°C at a heating rate of 5°C / min in an air atmosphere, and kept for 4 hours. And with furnace cooling, the resulting product was collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com