Ultra-fine soil concrete and preparation method thereof

A technology for concrete and concrete regeneration, applied in the field of civil engineering materials, can solve the problems of high cost of raw materials, health conditions, large demand for materials, etc., and achieve the effects of saving manpower and material resources, widening sources, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

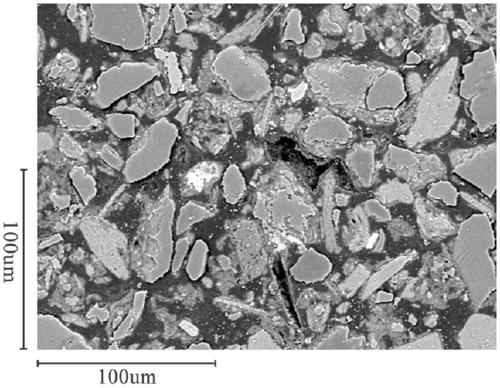

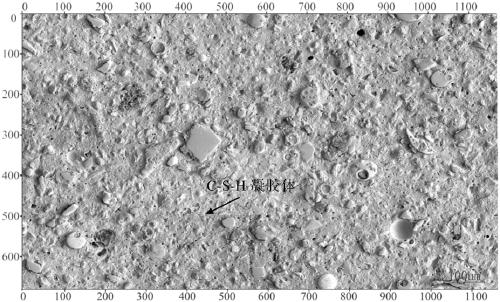

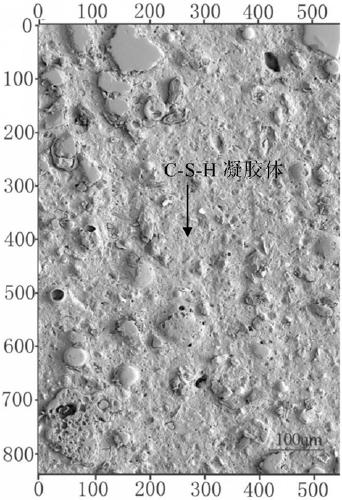

[0040] The ultra-fine soil concrete of this embodiment is made of the following components by mass: 1500 parts of loess, 400 parts of 42.5 ordinary Portland cement, 310 parts of grade I fly ash, 195 parts of silica fume, and 66 parts of concrete regeneration agent , 100 parts of iron-containing polypropylene fiber, 463 parts of water; the loess is ground to more than 90% of the ultrafine soil with a particle size of less than 1mm, and the silica fume is amorphous spherical particles, and SiO in silica fume 2 The mass content of not less than 83%, SiO 2 The specific surface area is not less than 15m 2 / g; The main components of the concrete regeneration agent are isoprenyl polyoxyethylene ether, hydrogen peroxide, vinyltriethoxysilane, sodium hydroxide, ferrous sulfate, acrylic acid, methallyl polyoxyethylene Ethylene glycol macromonomer, acrylic acid, ammonium persulfate, mercaptoacetic acid, branched active macromonomer and sodium bisulfite; the iron-containing polypropylene...

Embodiment 2

[0046] The ultra-fine soil concrete of this embodiment is made of the following components by mass: 1300 parts of loess, 243 parts of 42.5 ordinary Portland cement, 200 parts of Class I fly ash, 147 parts of silica fume, and 80 parts of concrete regeneration agent , 80 parts of iron-containing polypropylene fiber, 318 parts of water; the loess is ground to more than 90% of the ultrafine soil with a particle size of less than 1mm; the silica fume is amorphous spherical particles, and SiO in silica fume 2 The mass content of not less than 83%, SiO 2 The specific surface area is not less than 15m 2 / g; The main components of the concrete regeneration agent are isoprenyl polyoxyethylene ether, hydrogen peroxide, vinyltriethoxysilane, sodium hydroxide, ferrous sulfate, acrylic acid, methallyl polyoxyethylene Ethylene glycol macromonomer, acrylic acid, ammonium persulfate, mercaptoacetic acid, branched active macromonomer and sodium bisulfite; the iron-containing polypropylene fiber...

Embodiment 3

[0052] The ultra-fine soil concrete of this embodiment is made of the following components by mass: 1500 parts of loess, 380 parts of 42.5 ordinary Portland cement, 230 parts of grade I fly ash, 180 parts of silica fume, and 62 parts of concrete regeneration agent , 100 parts of iron-containing polypropylene fiber, 498 parts of water; the loess is ground to more than 90% of the ultrafine soil with a particle size of less than 1mm; the silica fume is amorphous spherical particles, and SiO in silica fume 2 The mass content of not less than 83%, SiO 2 The specific surface area is not less than 15m 2 / g; The main components of the concrete regeneration agent are isoprenyl polyoxyethylene ether, hydrogen peroxide, vinyltriethoxysilane, sodium hydroxide, ferrous sulfate, acrylic acid, methallyl polyoxyethylene Ethylene glycol macromonomer, acrylic acid, ammonium persulfate, mercaptoacetic acid, branched active macromonomer and sodium bisulfite; the iron-containing polypropylene fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com