Method for extracting xylose and lignin from wheat straw through vapor explosion and making wood pulp

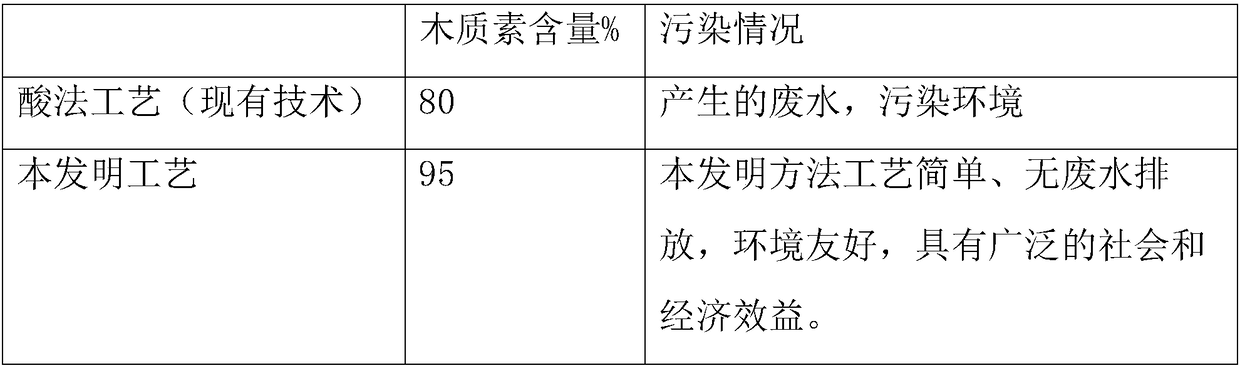

A technology of lignin and xylose, which is applied in the field of comprehensive utilization of wheat straw by steam explosion, can solve the problems of high cost, low content of xylitol, and shortage of corn cob raw materials, so as to increase economic and social benefits, protect the environment, and improve utilization value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

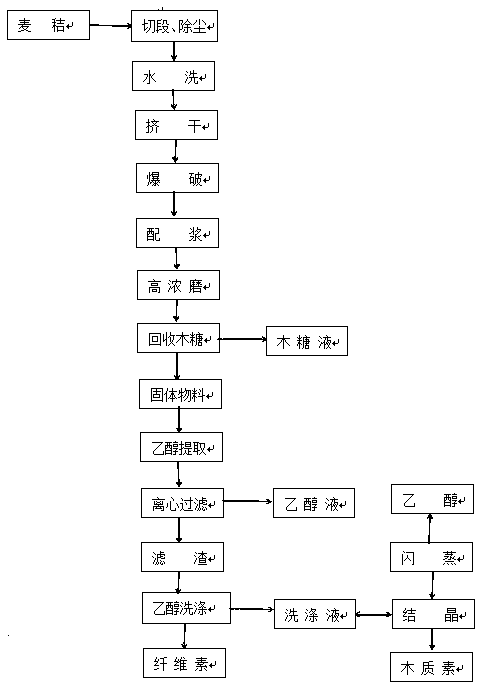

Method used

Image

Examples

Embodiment 1

[0034]Cut the raw wheat straw to a size of 3-5cm with a fully automatic grass cutter, and then use the rotary hammer of the grass cutter itself to cut the wheat straw into sections and fracturing without additional fracturing equipment, and then go through eight-roller dust removal to remove impurities and dust; the cut and dedusted wheat straw still contains some soil and other impurities. In order to remove these impurities and water-soluble pigments and soften the wheat straw to facilitate blasting, use 85°C hot water in a hot water scrubber Backwashing was performed once. The wheat straw washed with hot water is squeezed dry with a single-screw squeezer to make the moisture content of the material 50%; then the squeezed material is sent into the instant blaster, and the temperature is controlled by saturated steam at 180°C and pressure 1.8MPa , the residence time is 120s; to achieve instant blasting, and to obtain blasting materials rich in xylose; the blasting materials c...

Embodiment 2

[0036] Cut the raw wheat straw to a size of 3-5cm with a fully automatic grass cutter, and then use the rotary hammer of the grass cutter itself to cut the wheat straw into sections and fracturing without additional fracturing equipment, and then go through eight-roller dust removal to remove impurities and dust; the cut and dedusted wheat straw still contains some soil and other impurities. In order to remove these impurities and water-soluble pigments and soften the wheat straw to facilitate blasting, use 85°C hot water in a spiral grass washer. Perform backwashing. The wheat straw washed with hot water is squeezed dry with a single-screw squeezer to make the moisture content of the material 50%; then the squeezed material is sent into the instant blaster, and the temperature is controlled by saturated steam at 180°C and pressure 1.8MPa , the residence time is 120s; to achieve instant blasting, and to obtain blasting materials rich in xylose; the blasting materials containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com