A bendable PVC low-foam board and a preparing method thereof

A low-foaming and bending technology, which is used in flexible PVC low-foaming panels, mainly used in wall decoration or space partitions, and in the processing of architectural decorative panels. problems, to achieve the effect of enhancing toughness and impact resistance, improving structural strength, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

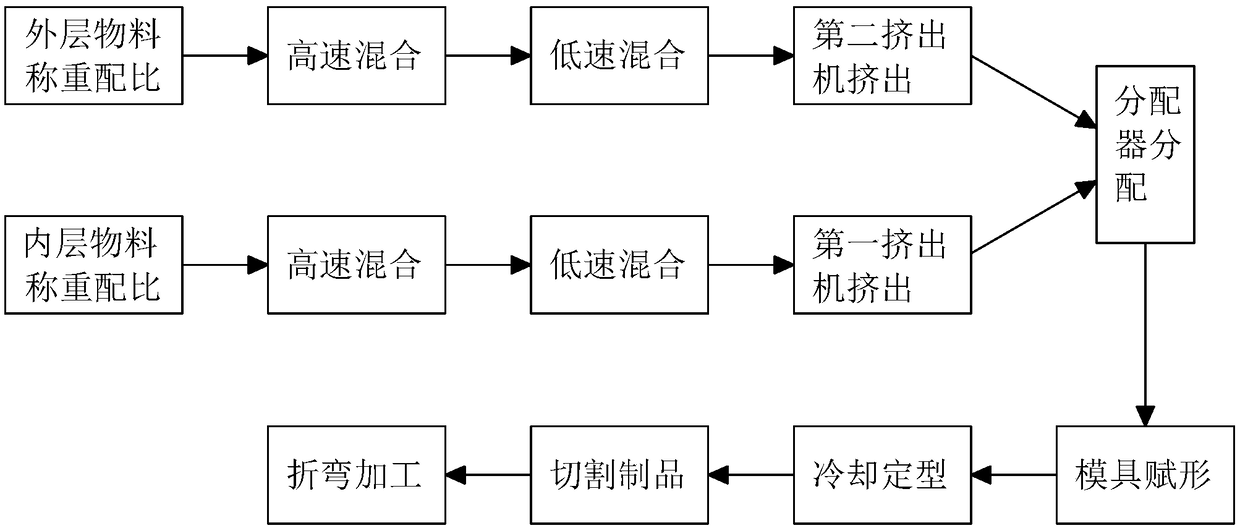

Method used

Image

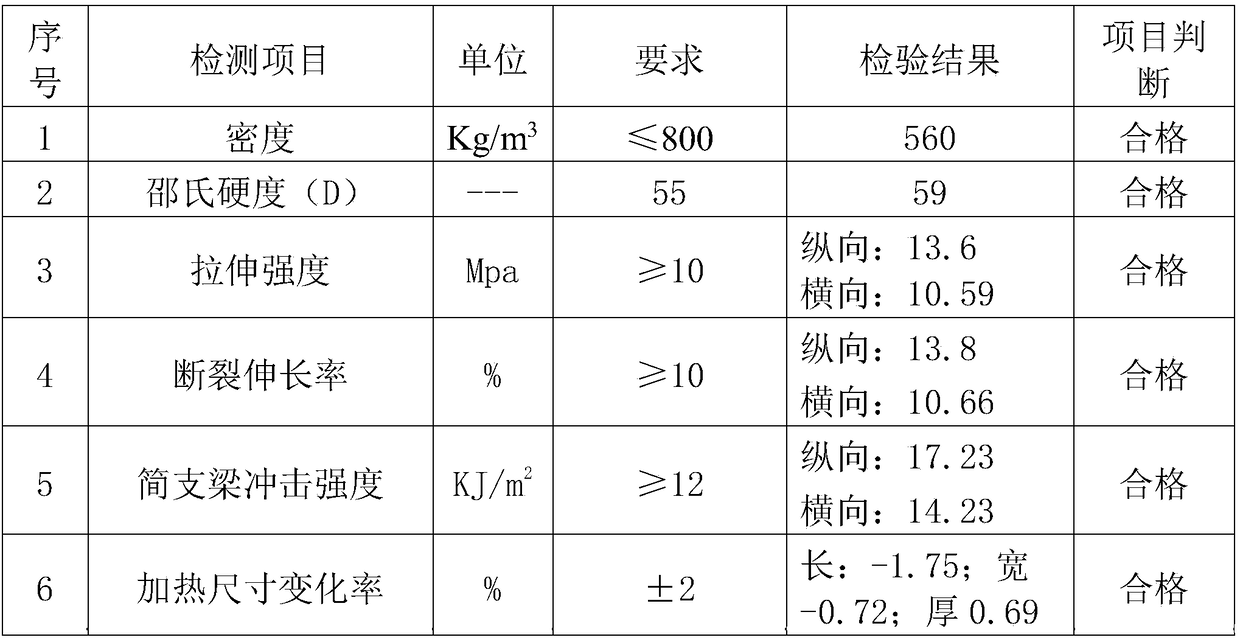

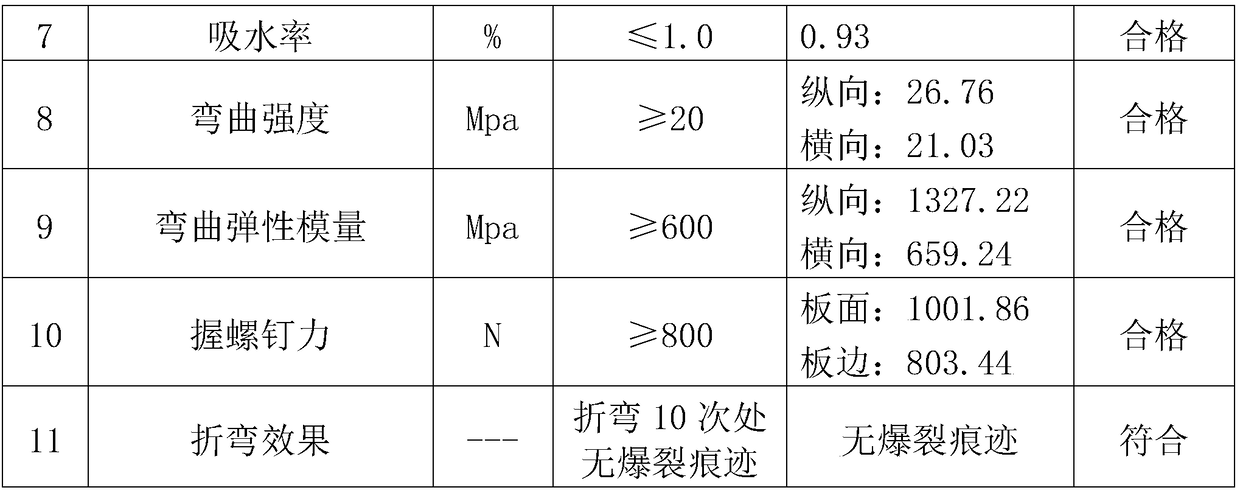

Examples

Embodiment 1

[0027] A bendable PVC low-foaming board provided by the present invention includes an intermediate layer, an outer layer is attached to the upper and lower surfaces of the intermediate layer, the two outer layers are respectively a PVC material layer, and the middle layer The first layer is a PVC low-foaming layer, and the PVC material layer and the low-foaming layer are integrally formed by co-extrusion, so that the low-foaming layer and the PVC material layer are closely combined.

[0028] The PVC material layer includes material components in the following weight ratio: 100 parts of PVC resin; 5.6 parts of calcium zinc stabilizer as heat stabilizer; 1 part and 1 part of lubricant as G60, stearic acid and polyethylene wax respectively and 1.2 parts to form 3.2 parts; the plasticizer can adopt oxidized polyethylene wax, epoxy soybean oil or its combination, and the present embodiment adopts 2.6 parts of epoxy soybean oil; the processing aid adopts ACR impact modifier and poly ...

Embodiment 2

[0042] Different from Example 1 in that:

[0043] The PVC material layer includes material components in the following weight ratio: 100 parts of PVC resin; 4 parts of calcium zinc stabilizer as heat stabilizer; 0.8 parts of G60, 0.8 parts of stearic acid and polyethylene wax as lubricant and 1 part are mixed to form 2.6 parts; the plasticizer can adopt oxidized polyethylene wax, epoxy soybean oil or its combination, and the present embodiment adopts 3 parts of epoxy soybean oil; the processing aid adopts ACR impact modifier and chlorine A total of 10 parts of polyethylene.

[0044] The low-foaming layer includes material components in the following weight ratio: 100 parts of PVC resin; 4 parts of calcium zinc stabilizer as heat stabilizer; 0.8 parts of G60, stearic acid and polyethylene wax as lubricant, 0.8 parts 1 part and 1 part are mixed to form 2.6 parts; the plasticizer can adopt oxidized polyethylene wax, epoxidized soybean oil or its combination, and the present embo...

Embodiment 3

[0047] Different from Example 1 in that:

[0048] The PVC material layer includes material components in the following weight ratio: 100 parts of PVC resin; 3 parts of calcium zinc stabilizer as heat stabilizer; 0.2 part and 0.2 part of lubricant as G60, stearic acid and polyethylene wax respectively and 0.2 parts are mixed to form 0.6 parts; the plasticizer can adopt oxidized polyethylene wax, epoxy soybean oil or its combination, and the present embodiment adopts 2 parts of epoxy soybean oil; the processing aid adopts ACR impact modifier and poly A total of 6 parts of vinyl chloride.

[0049] The low-foaming layer includes material components in the following weight ratio: 100 parts of PVC resin; 4 parts of calcium zinc stabilizer as heat stabilizer; 0.8 parts of G60, stearic acid and polyethylene wax as lubricant, 0.8 parts 1 part and 1 part are mixed to form 2.6 parts; the plasticizer can adopt oxidized polyethylene wax, epoxy soybean oil or its combination, and the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com