Nanometer polyurethane flame-retardant waterproof coating and a preparing method thereof

A waterproof coating and polyurethane technology, applied in polyurea/polyurethane coatings, fireproof coatings, coatings, etc., can solve the problems of chalking, slow drying speed, poor weather resistance, etc., and achieve the effect of improving aging resistance and speeding up drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of modified magnesium aluminum hydrotalcite includes the following steps:

[0024] Add magnesium-aluminum hydrotalcite and monohydroxy polydimethylsiloxane to glycerin, and perform ultrasonic dispersion to obtain a dispersion. The dispersion is heated to 90°C, and then the silane coupling agent KH550 and water are added sequentially, and the mixture is stirred and reacted evenly. 8h, cool down to 60℃ and add polypropylene imine to react for 3h.

[0025] The mass ratio of monohydroxy polydimethylsiloxane to magnesium aluminum hydrotalcite is 1:12, the mass ratio of silane coupling agent KH550 and magnesium aluminum hydrotalcite is 1:26, polypropylene imine and magnesium aluminum water The mass ratio of talc is 3:100.

Embodiment 2

[0027] The preparation method of modified magnesium aluminum hydrotalcite includes the following steps:

[0028] Add magnesium-aluminum hydrotalcite and monohydroxy polydimethylsiloxane to glycerin and perform ultrasonic dispersion to obtain a dispersion. The dispersion is heated to 80°C, and then the silane coupling agent KH560 and water are added in sequence, and the mixture is stirred and reacted evenly. 4h, cool down to 50℃ and add polypropylene imine to react for 6h.

[0029] The mass ratio of monohydroxy polydimethylsiloxane and magnesium aluminum hydrotalcite is 1:9, the mass ratio of silane coupling agent KH560 and magnesium aluminum hydrotalcite is 1:20, polypropylene imine and magnesium aluminum hydrotalcite The mass ratio of talc is 6:100.

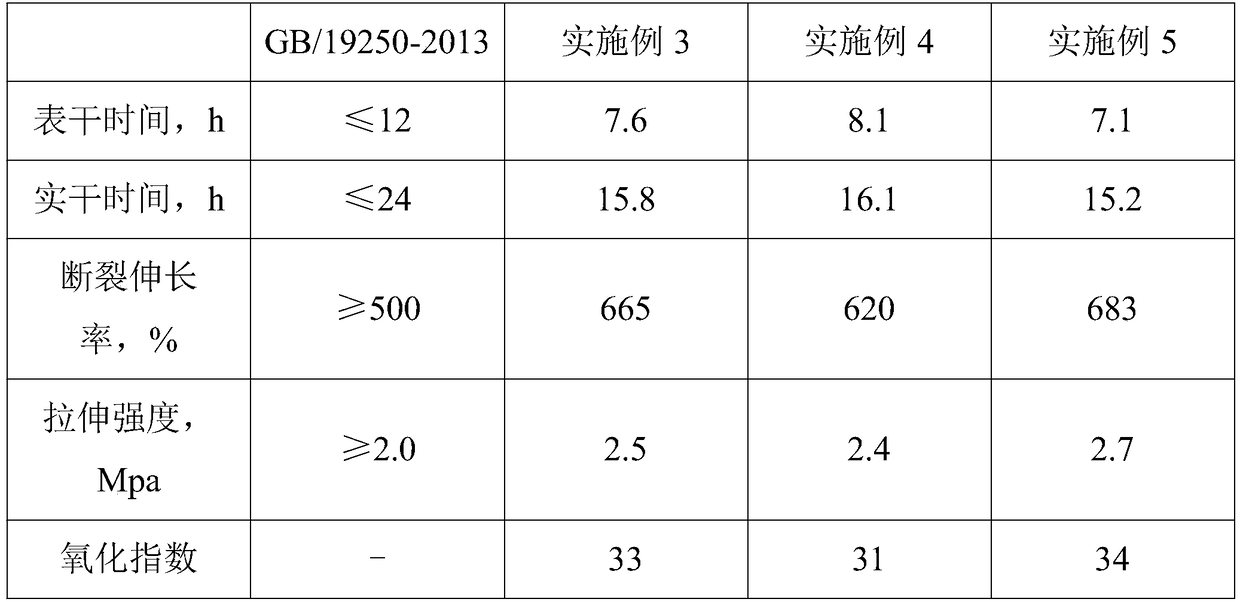

Embodiment 3

[0031] A nano-polyurethane flame-retardant waterproof coating, calculated in parts by weight, including the following components:

[0032] 46 parts of polyether diol, 25 parts of diphenylmethylene diisocyanate, 1 part of trimethylolpropane, 15 parts of hydroxymethyl acrylate, 36 parts of didecyl phthalate, modification of Example 1 34 parts of magnesium aluminum hydrotalcite, 15 parts of nano calcium carbonate, 15 parts of nano magnesium hydroxide, 1 part of dibutyl tin dilaurate, 1 part of defoamer and 35 parts of solvent.

[0033] Preparation:

[0034] 1) Add polyether polyol, hydroxymethyl acrylate, didecyl phthalate, nano-calcium carbonate, nano-magnesium hydroxide and the modified magnesium aluminum hydrotalcite of Example 1 into the reaction kettle, stir and mix, and heat up To 100°C, then vacuum drying and dehydration;

[0035] 2) After reducing the temperature of the reactor to 80°C, add diphenylmethylene diisocyanate and react for 2 hours while stirring;

[0036] 3) Cool down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com