White EVA packaging adhesive film and preparation method thereof

An encapsulation film, white technology, applied in the direction of adhesive, film/sheet adhesive, film/sheet without carrier, etc., can solve the problem of low reflectivity of white EVA film, affecting the appearance of components, restricting power improvement, etc. problems, to optimize the preparation steps and process parameters, improve the power generation efficiency, and improve the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

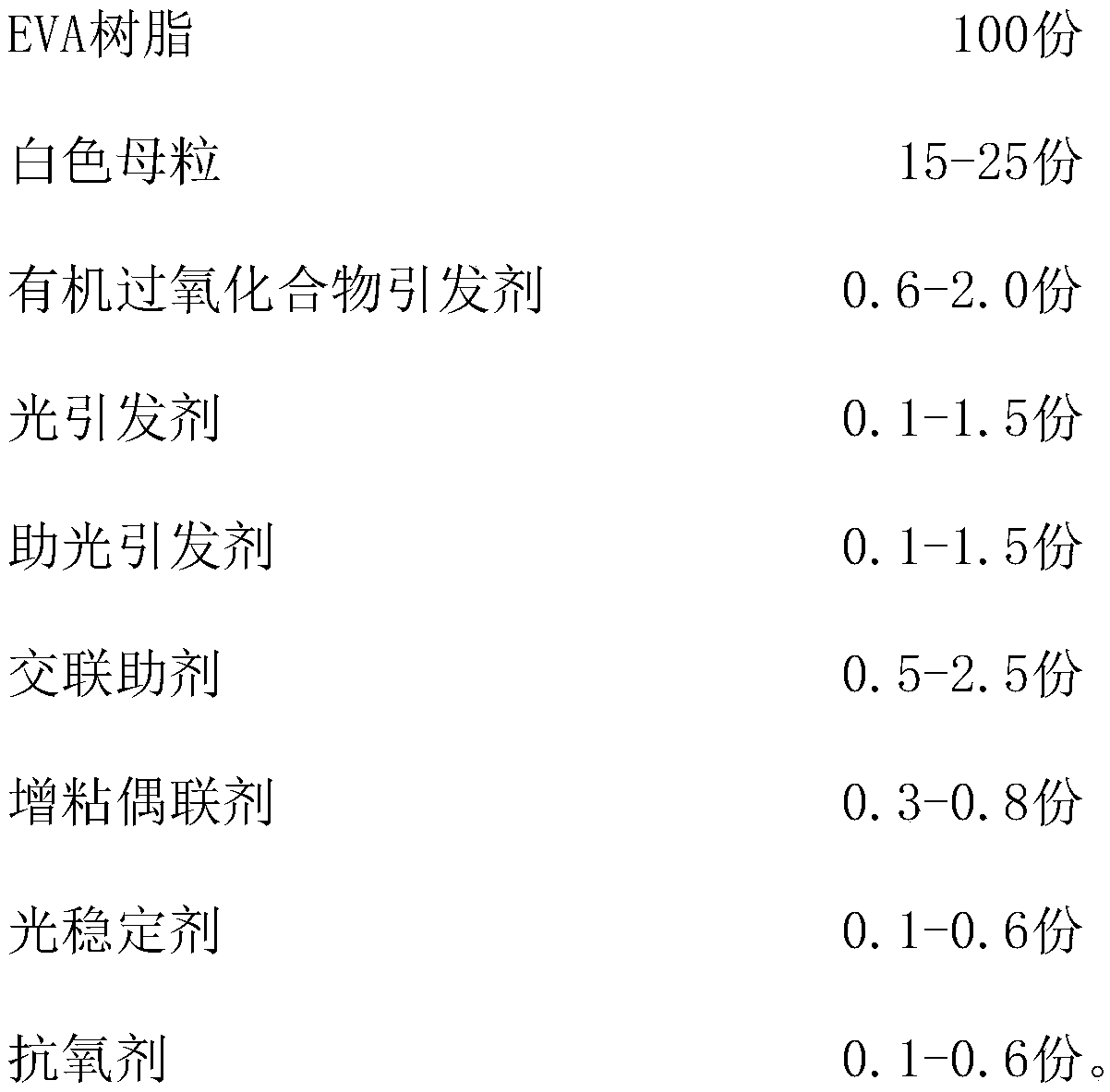

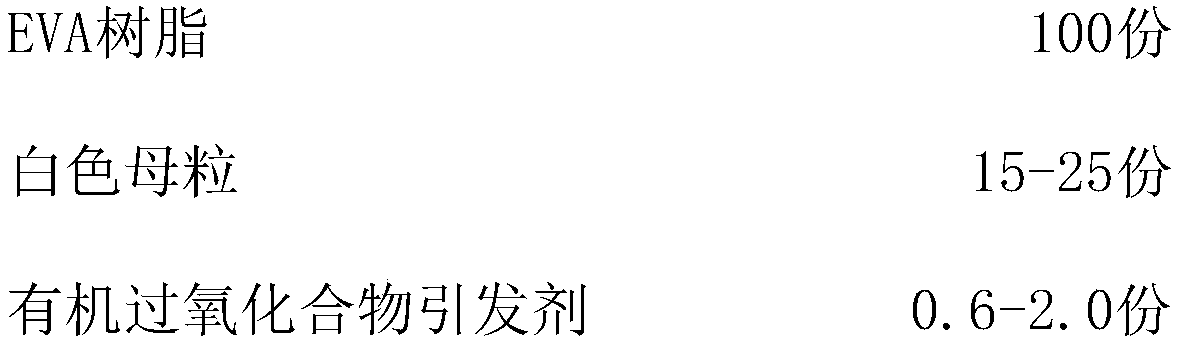

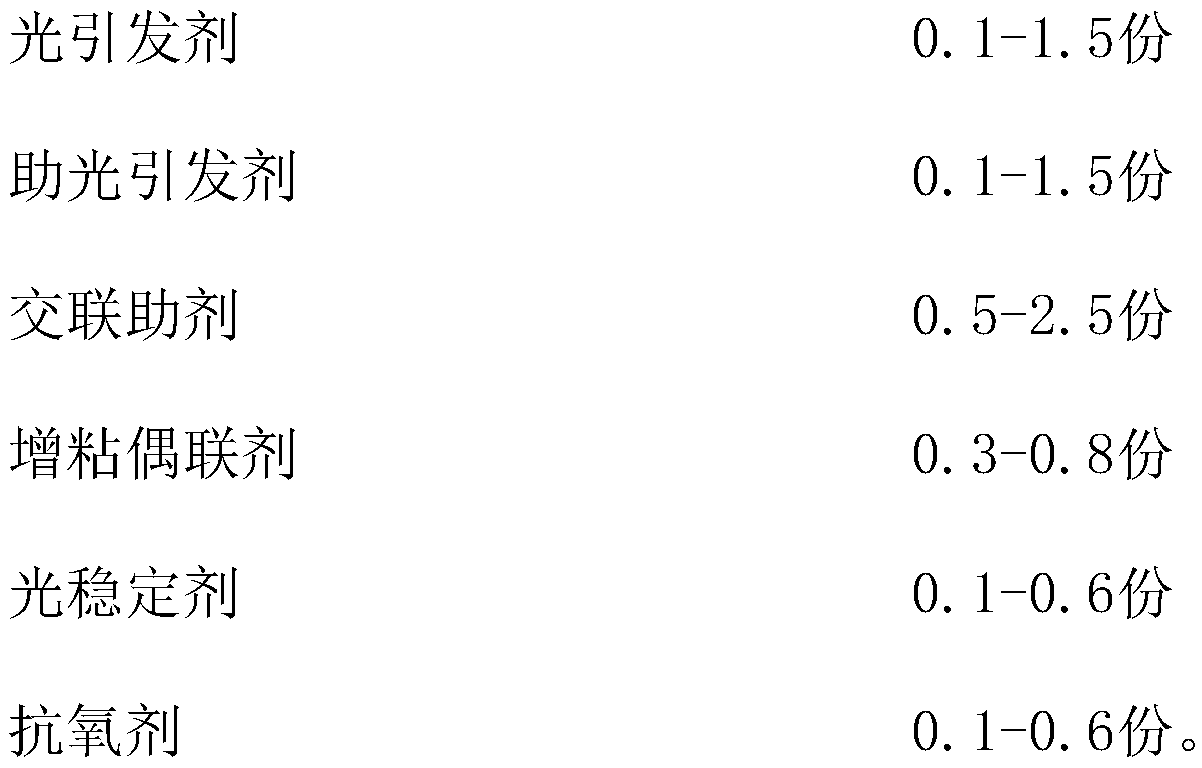

[0041] A preparation method for a white EVA encapsulation film, comprising the following steps:

[0042] Mixing step: Weigh each raw material according to the formula ratio, and mix them evenly through the mixing tank to obtain the mixed material;

[0043] Film forming step: put the mixture into the casting machine, and make a white EVA packaging film through plasticizing extrusion, casting, traction and winding. The thickness of the white EVA packaging film is 0.1mm-1.0mm;

[0044] UV lamp irradiation steps: After the white EVA packaging film is irradiated by a 300-400nm ultraviolet lamp, a UV pretreated white EVA packaging film with a certain degree of latent crosslinking is obtained; among them, the cumulative irradiation energy is 6000mj / cm-12000mj / cm, the latent cross-linking degree is between 10-60%.

Embodiment 1

[0047] The present embodiment provides a kind of preparation method of white EVA encapsulating adhesive film, comprising:

[0048] Mixing step: Weigh 100 parts by weight of EVA resin with a melt index of 3g / 10min, a VA content of 20, and a melting point of 115°C, 15 parts of white masterbatch, and 2.0 parts of carbaperoxyacid-O,O-(1 , 1-dimethylethyl)-O-(2-ethylhexyl) ester (organic peroxide initiator), 1.5 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone (light initiator), 1.5 parts of 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholinyl)-1-propanone (co-photoinitiator), 0.6 parts of triene Propyl isocyanurate (crosslinking aid), 0.8 parts of vinyltriethoxysilane (adhesive coupling agent), 0.6 parts of [2-hydroxy-4-(octyloxy)phenyl]phenyl Ketone (light stabilizer), 0.6 parts of 2,6-bis(1,1-dimethylethyl)-4-methylphenol (antioxidant); mix the above components uniformly through a mixing tank to obtain a mixed material;

[0049] Film forming step: put the mixture into the casti...

Embodiment 2

[0053] The present embodiment provides a kind of preparation method of white EVA encapsulating adhesive film, comprising:

[0054] Mixing steps: Weigh 100 parts by weight of EVA resin with a melt index of 10g / 10min, a VA content of 24, and a melting point of 100°C, 18 parts of white masterbatch, and 1.5 parts of tert-butyl peroxycarbonate-2-ethyl Hexyl ester (organic peroxide initiator), 1.2 parts of 2-hydroxyl-2-methylphenyl propane-1-ketone (photoinitiator), 1.2 parts of 1-hydroxycyclohexyl phenyl ketone (co-photoinitiator ), 0.8 parts of triallyl isocyanurate (cross-linking aid), 0.7 parts of ethylene triethoxysilane (adhesive coupling agent), 0.5 parts of 2-hydroxy-4-n-octyloxydi Benzophenone (light stabilizer), 0.5 part tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (antioxidant); the above components are passed through the mixing tank Mix evenly to obtain a mixture;

[0055] Film forming step: Put the mixture into the casting machine, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com