Near-infrared luminescent material and light-emitting device prepared from same

A technology of light-emitting materials and light-emitting devices, applied in the directions of light-emitting materials, semiconductor devices, chemical instruments and methods, etc., can solve the problems of low light-emitting efficiency, poor stability and high preparation cost, and achieve high light-emitting efficiency, low cost and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the luminescent material of the present invention can be prepared by methods known in the art, such as high-temperature solid-phase method, the present invention is preferably an oxide, fluoride, carbonate or chloride of R element, Q element Oxides, fluorides, carbonates or chlorides of Cr, oxides, fluorides or carbonates of Cr, oxides, fluorides or carbonates of Yb, and the raw materials are accurately weighed according to a certain stoichiometric ratio , at a temperature of 1400-1500° C., calcined in an atmosphere of air, nitrogen and / or hydrogen for 2-20 hours to obtain a calcined product, and the calcined product is post-treated to obtain the desired phosphor. Among them, post-processing includes crushing, washing (water washing or weak acid washing, etc.), classification, etc.

[0054] The manufactured device includes a phosphor and an excitation light source, and the phosphor includes the above-mentioned near-infrared luminescent material...

Embodiment 1

[0057] The near-infrared luminescent material described in this embodiment contains an inorganic compound whose composition formula is Y 2.92 Ga 4.4 o 11.25 :Cr 0.10 ,Yb 0.08 .

[0058] The near-infrared luminescent material described in this embodiment is represented by Y 2 o 3 , Ga 2 o 3 、Cr 2 o 3 , Yb 2 o 3 As raw material, according to its composition is Y 2.92 Ga 4.4 o 11.25 :Cr 0.10 ,Yb 0.08 The stoichiometric ratio of the raw materials is accurately weighed, roasted at 1400° C. in air for 5 hours to obtain a roasted product, and the roasted product is crushed, washed with water, and dried to obtain the required luminescent material.

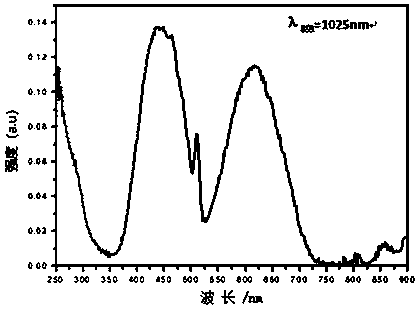

[0059] The excitation spectrum of the obtained luminescent material was measured as figure 1 , whose monitoring wavelength is 1025nm. From figure 1 It can be seen that the luminescent material prepared in this example can be effectively excited in the range of 250-300nm, 400-500nm, and 550-700nm. Light has strong broadb...

Embodiment 2

[0066] The near-infrared luminescent material described in this embodiment, the compound composition formula it comprises is Y 3.38 Ga 4.9 o 12.66 :Cr 0.10 ,Yb 0.06 .

[0067] According to chemical formula Y 3.38 Ga 4.9 o 12.66 :Cr 0.10 ,Yb 0.06 stoichiometric ratio, accurately weigh Y 2 o 3 , Ga 2 o 3 、Cr 2 o 3 and Yb 2 o 3 Mix to obtain a mixture; after the mixture is ground and mixed, it is calcined at 1500°C for 5 hours, and the roasted product is obtained after cooling down; the obtained roasted product is subjected to post-processing such as crushing, grinding, grading, and sieving to obtain a near-infrared Phosphor samples.

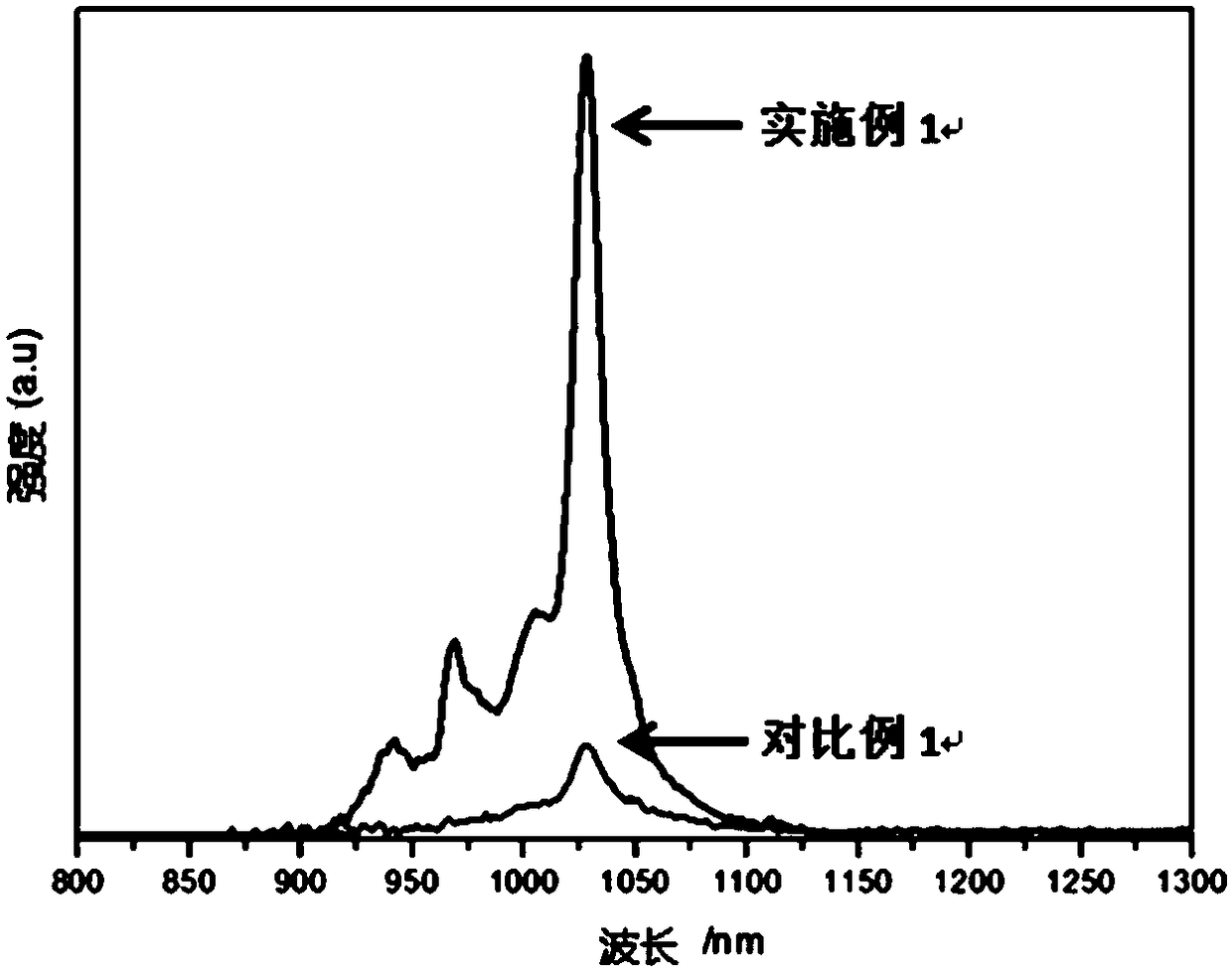

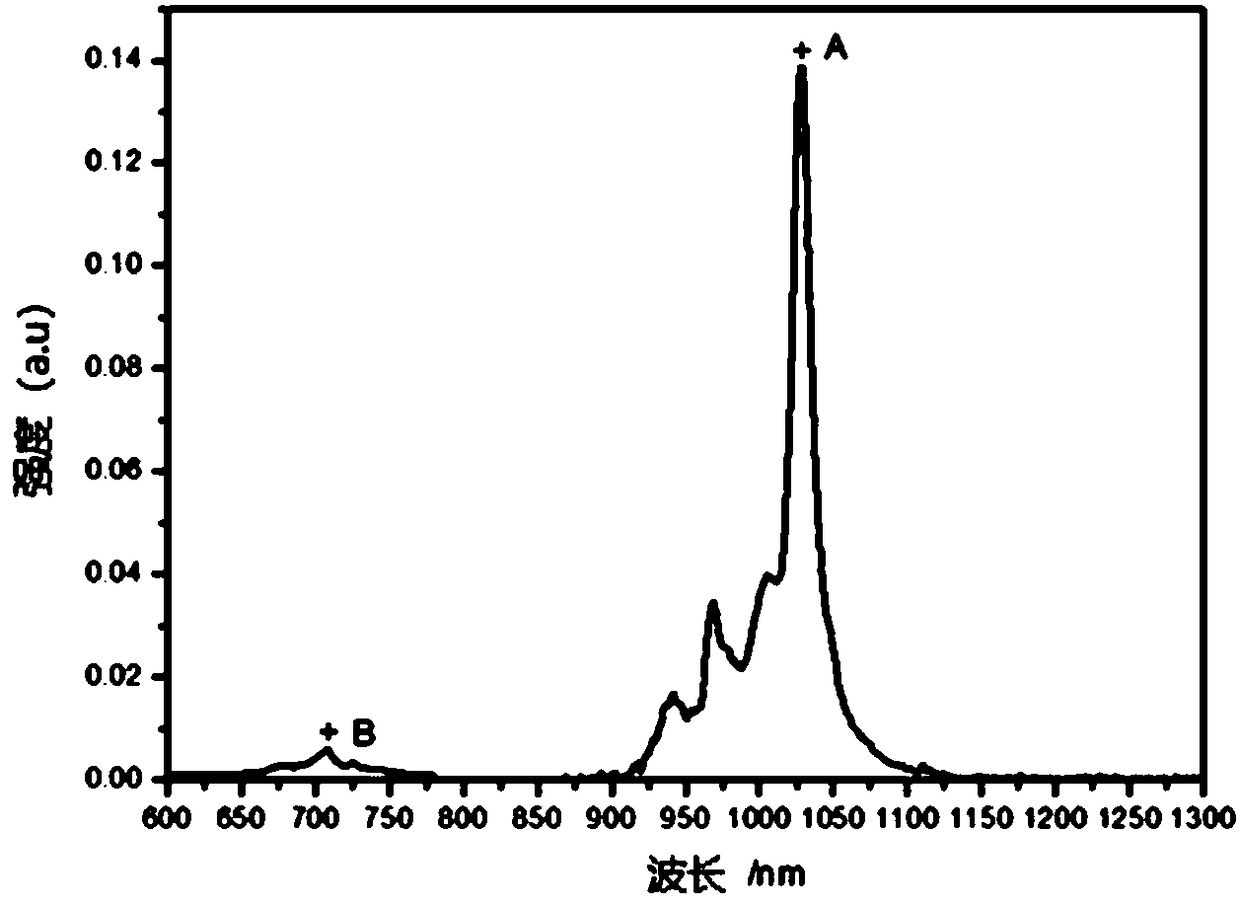

[0068] The obtained near-infrared phosphor sample is subjected to an excitation test, the excitation wavelength is 460nm, and its infrared emission spectrum is as follows: image 3 shown. The results show that the near-infrared phosphor sample can emit short-wave near-infrared light of 900-1100nm under the excitation of 460nm. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com