Method for oligomerization of ethylene to alpha-olefins and pretreatment method of catalyst and solvent thereof

A catalyst and pretreatment technology, applied in the direction of carbon compound catalysts, catalysts, chemical instruments and methods, etc., can solve problems affecting catalyst activity, reduce ethylene partial pressure, etc., achieve reduced material loss, reduced ethylene unit consumption, and stable reaction activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

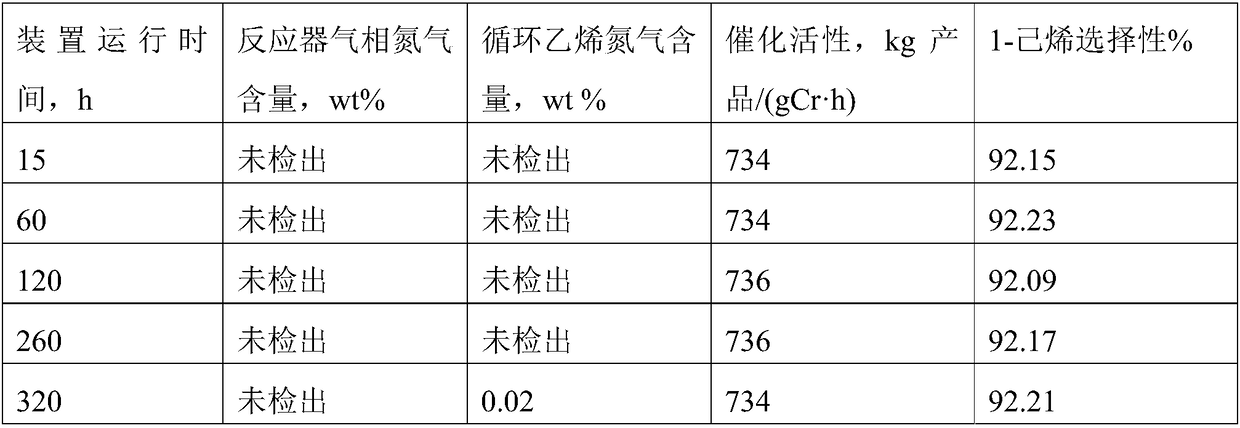

Embodiment 1

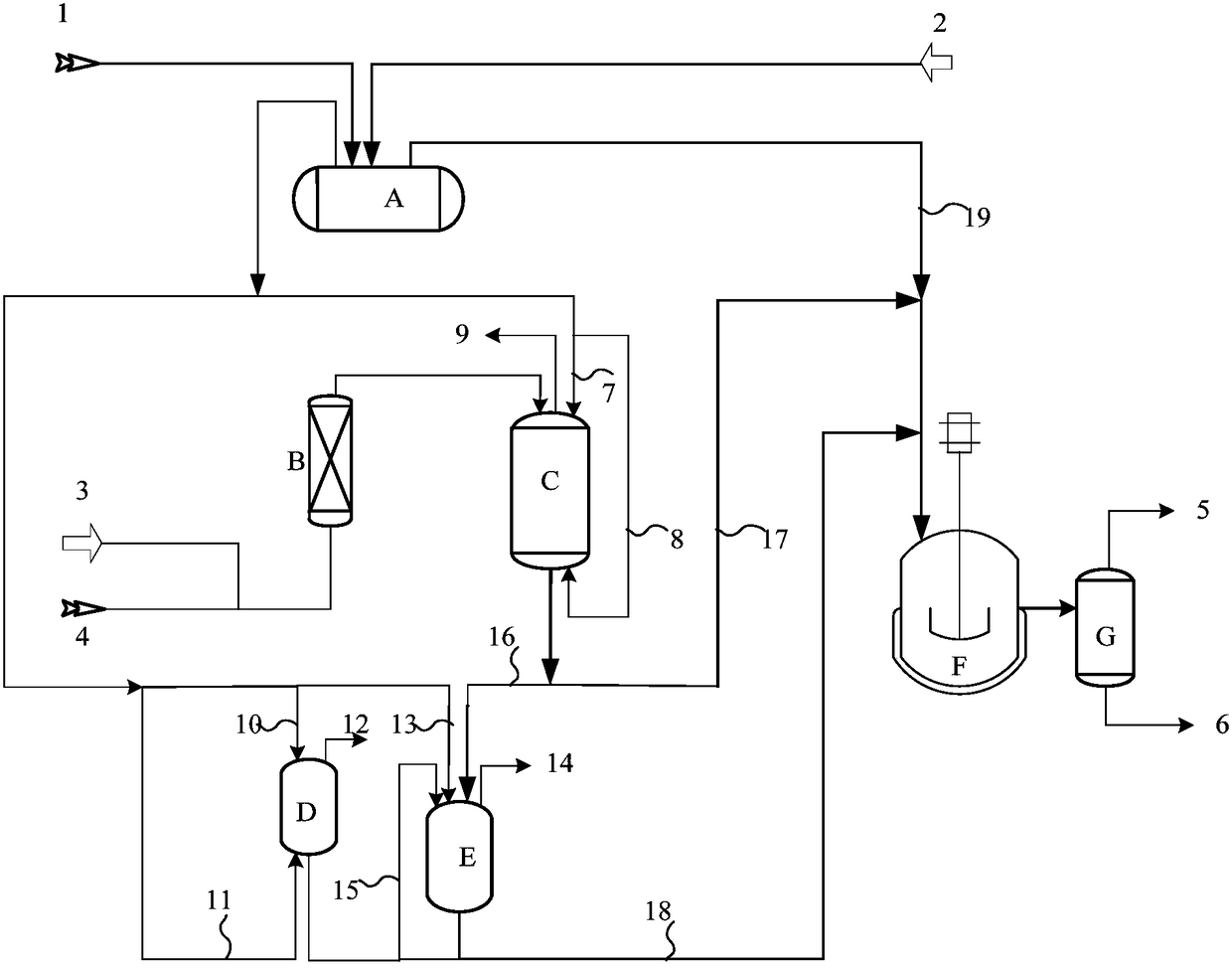

[0066] This embodiment is a process for ethylene trimerization to 1-hexene. The catalyst system and solvent system are packed with polymer grade ethylene. The specific operation is as follows: (the holding pressure is 0.15MPa)

[0067] The solvent cyclohexane is dehydrated and refined with ethylene (via attached figure 1 The bubbling line of the medium refining solvent tank 8) enters the bubbling replacement from the bottom of the refining solvent tank C for 5 minutes, and then ethylene (via attached figure 1 Medium-refined solvent tank holding pressure line 7) holding pressure 0.15MPa.

[0068] The catalyst is a system of four components, namely: chromium isooctanoate (5wt%), 2,5-dimethylpyrrole (5wt%), triethylaluminum (50wt%), hexachlorocyclohexane (25wt%) ), and the rest are solvents. The four catalyst components are separated by the catalyst tank (attached figure 1 Middle catalyst receiving tank D, four in total) after receiving, use ethylene (through attached figur...

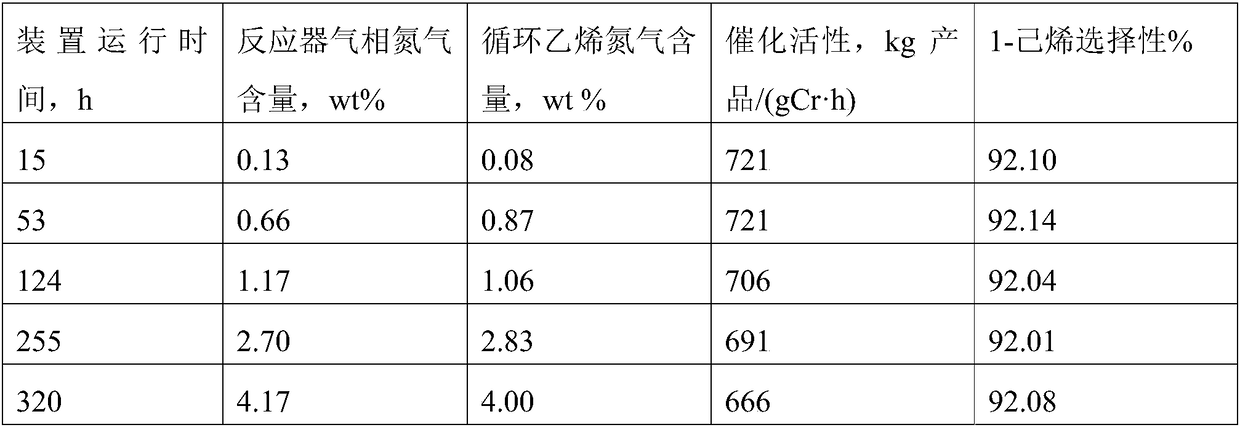

Embodiment 2

[0077] This embodiment is a process for ethylene trimerization to 1-hexene. The catalyst system and solvent system are packed with polymer grade ethylene. The specific operation is as follows: (the holding pressure is 0.2MPa)

[0078] The solvent n-heptane is dehydrated and refined with ethylene (via attached figure 1 The bubbling line of the medium refining solvent tank 8) enters the bubbling replacement from the bottom of the refining solvent tank C for 10 minutes, and then ethylene (via attached figure 1 Medium refining solvent tank pressure holding line 7) holding pressure 0.2MPa.

[0079] The catalyst is a four-component system, namely: chromium isooctanoate (2wt%), 2,5-dimethylpyrrole (2wt%), triethylaluminum (25wt%), 1,4-(two) tri Chloromethyl-2,3,5,6-tetrachlorobenzene (8wt%) and the rest are solvents. The four catalyst components are separated by the catalyst tank (attached figure 1 Middle catalyst receiving tank D, four in total) after receiving, use ethylene (t...

Embodiment 3

[0089] This embodiment is a process for ethylene oligomerization to α-olefins, wherein the selectivity of 1-octene is greater than 70%, and the sum of the selectivities of 1-hexene and 1-octene reaches more than 90%. The catalyst system and solvent system are packed with polymer grade ethylene. The specific operation is as follows: (the holding pressure is 1.0MPa)

[0090] The solvent cyclohexane is dehydrated and refined with ethylene (via attached figure 1 The bubbling line of the medium refining solvent tank 8) enters the bubbling replacement from the bottom of the refining solvent tank C for 10 minutes, and then ethylene (via attached figure 1 The medium-refined solvent tank pressure-holding line 7) maintains a pressure of 1.0MPa.

[0091] The catalytic system is a catalyst with five components, namely: chromium acetylacetonate (0.01mol / L), (diphenyl) phosphorus nitrogen (cyclopropyl) phosphorus (diphenyl) (0.02mol / L), methyl Aluminoxane (0.5mol / L), tetrachloroethane (0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com