Preparation method of low-peroxide value and zero-plasticizer omega-3 and omega-6 series greases

A technology of peroxide value and plasticizer, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of solvent residue, high cost, large equipment investment, etc., and achieve the effect of low peroxide value and reduction of processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

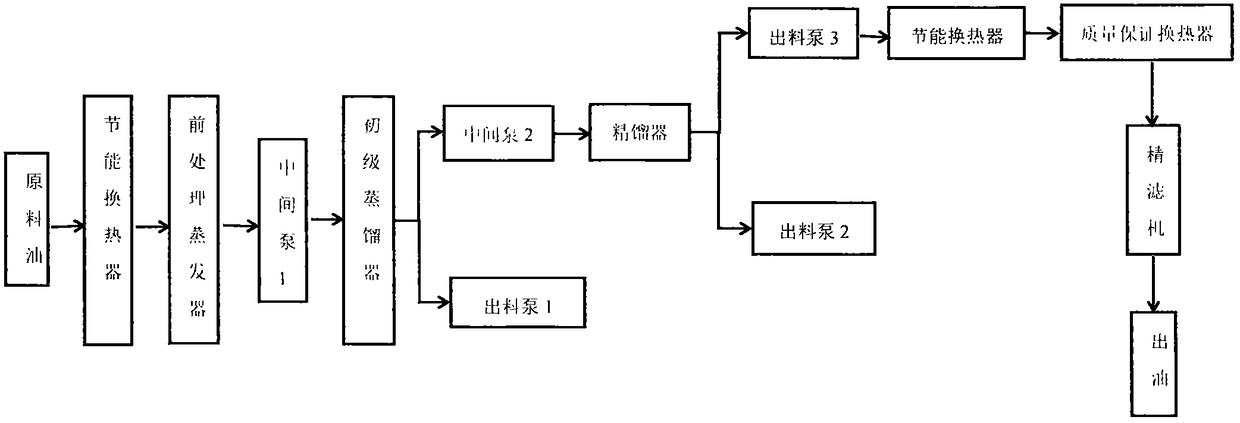

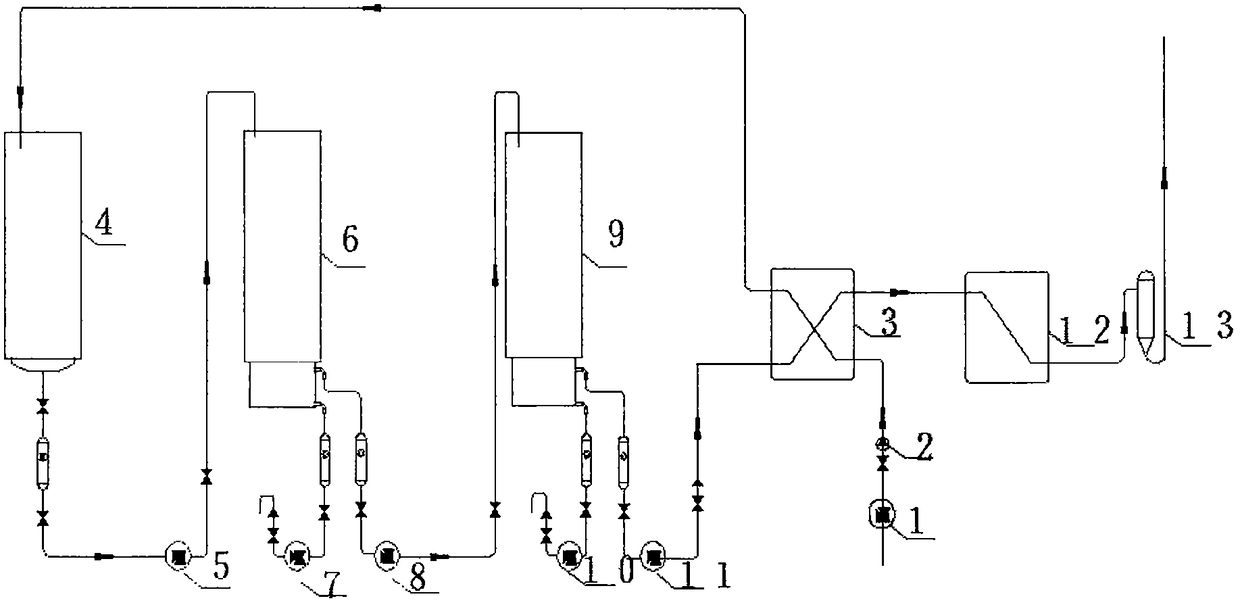

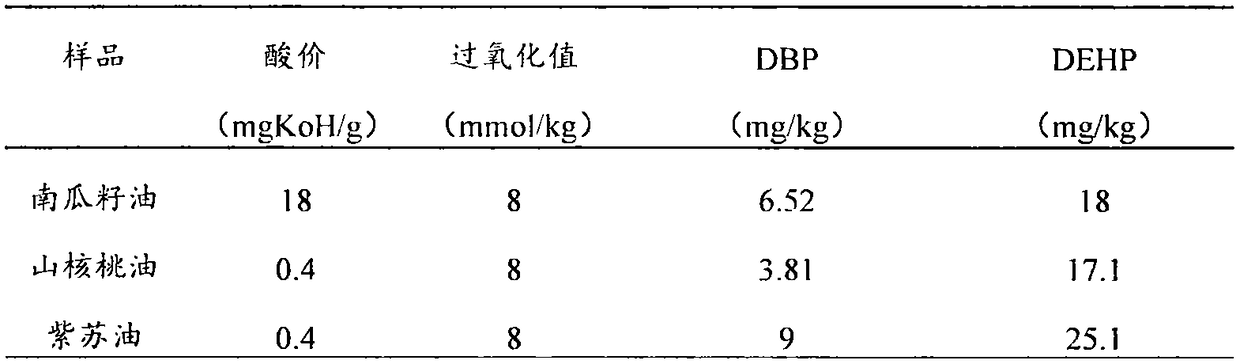

[0038] Turn on the equipment for removing plasticizers in Ω-3 and Ω-6 oils by low-temperature molecular distillation, and adjust the process parameters of the equipment, including flow meter 135L / H, primary distiller temperature 175°C, rectifier temperature 180°C, primary distillation The vacuum degree of the rectifier is ≤10.0pa, the vacuum degree of the rectifier is ≤5.0pa, and the cooling water temperature is 25°C; when the equipment execution parameters reach the set value, the feeding is carried out. The pumpkin seed oil is sent to the flowmeter by the feed metering pump, and then sent to the energy-saving heat exchanger after precise metering, and then sent to the pretreatment evaporator, and then sent to the primary still for distillation through the intermediate pump 1, and the primary still distills about 70% Pollutants such as plasticizers and solvent residues are distilled out by the discharge pump 1, and the remaining oil is sent to the rectifier by the intermediate...

Embodiment 2

[0040] Turn on the equipment for removing plasticizers in Ω-3 and Ω-6 oils by low-temperature molecular distillation, and adjust the process parameters of the equipment, including flow meter 90L / H, primary distiller temperature 175°C, rectifier temperature 180°C, primary distillation The vacuum degree of the rectifier is ≤10.0pa, the vacuum degree of the rectifier is ≤5.0pa, and the cooling water temperature is 25°C; when the equipment execution parameters reach the set value, the feeding is carried out. The hickory oil is sent into the flowmeter by the feed metering pump, and then sent to the energy-saving heat exchanger after precise metering, and then sent to the pretreatment evaporator, and then sent to the primary still for distillation through the intermediate pump 1, and the primary still distills about 70% Pollutants such as plasticizers and solvent residues are distilled out by the discharge pump 1, and the remaining oil is sent to the rectifier by the intermediate pum...

Embodiment 3

[0042] Turn on the equipment for removing plasticizers in Ω-3 and Ω-6 oils by low-temperature molecular distillation, and adjust the process parameters of the equipment, including flow meter 90L / H, primary distiller temperature 175°C, rectifier temperature 180°C, primary distillation The vacuum degree of the rectifier is ≤10.0pa, the vacuum degree of the rectifier is ≤5.0pa, and the cooling water temperature is 25°C; when the equipment execution parameters reach the set value, the feeding is carried out. The perilla oil is sent into the flow meter by the feed metering pump, and then sent to the energy-saving heat exchanger after precise metering, and then sent to the pretreatment evaporator, and then sent to the primary still for distillation through the intermediate pump 1, and the primary still distills about 70% Pollutants such as plasticizers and solvent residues are distilled out by the discharge pump 1, and the remaining oil is sent to the rectifier by the intermediate pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com