A nickel-doped copper oxide thin film transistor and a preparation method thereof

A thin-film transistor and copper oxide technology, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as difficult preparation of p-type metal oxide thin films, and achieve less hole scattering and high hole transport capacity , The effect of improving the quality of the contact interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

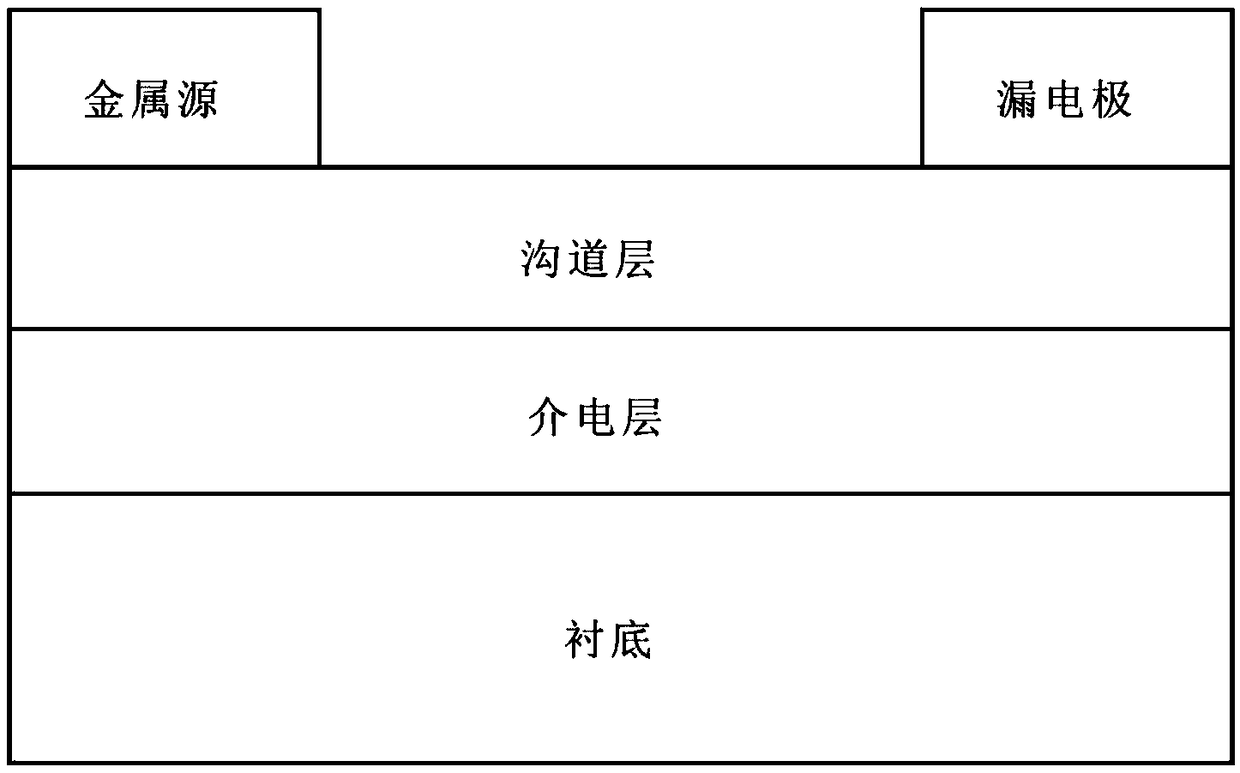

[0022] refer to figure 1 , a kind of preparation method of nickel-doped copper oxide thin film transistor, it comprises the steps:

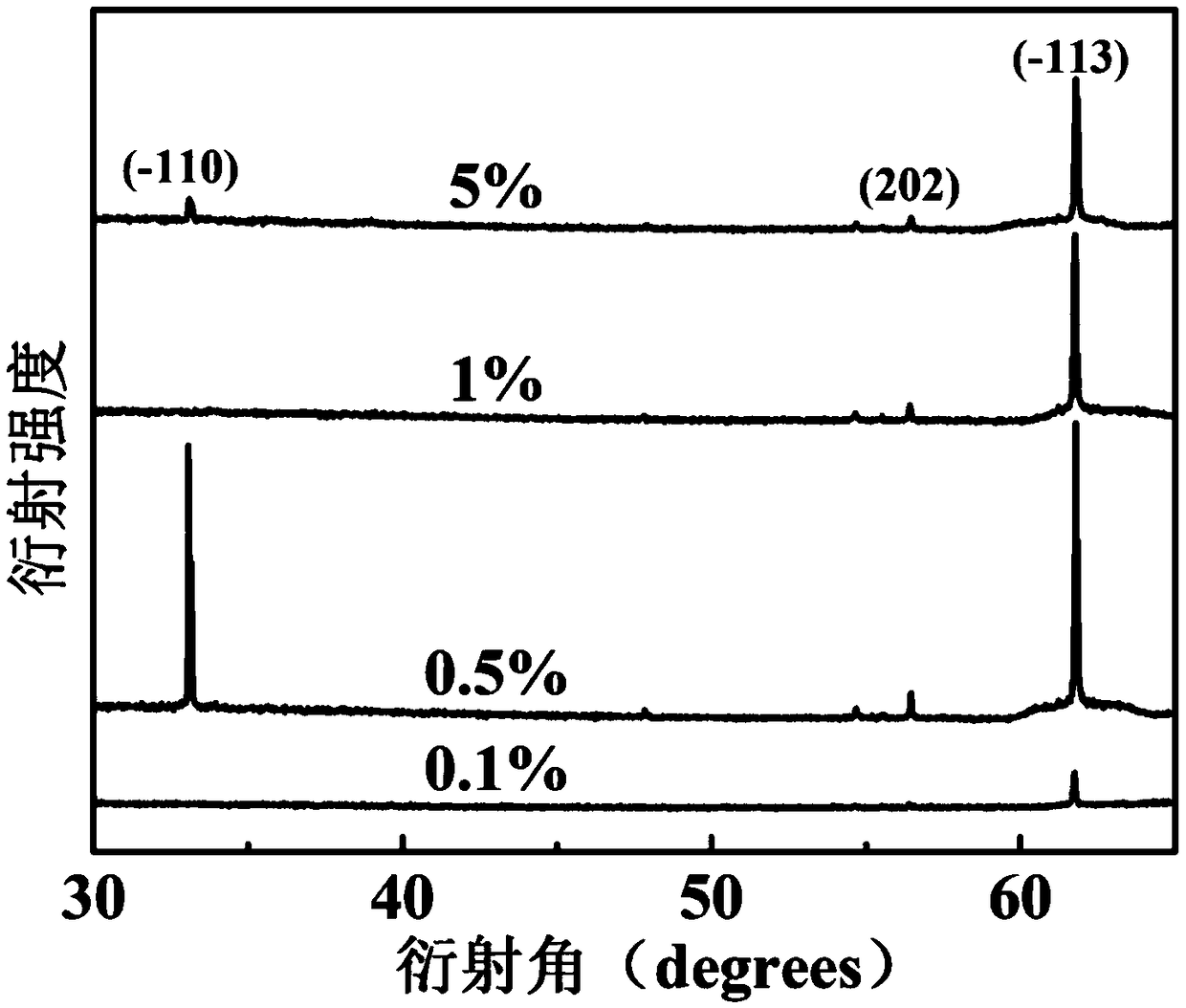

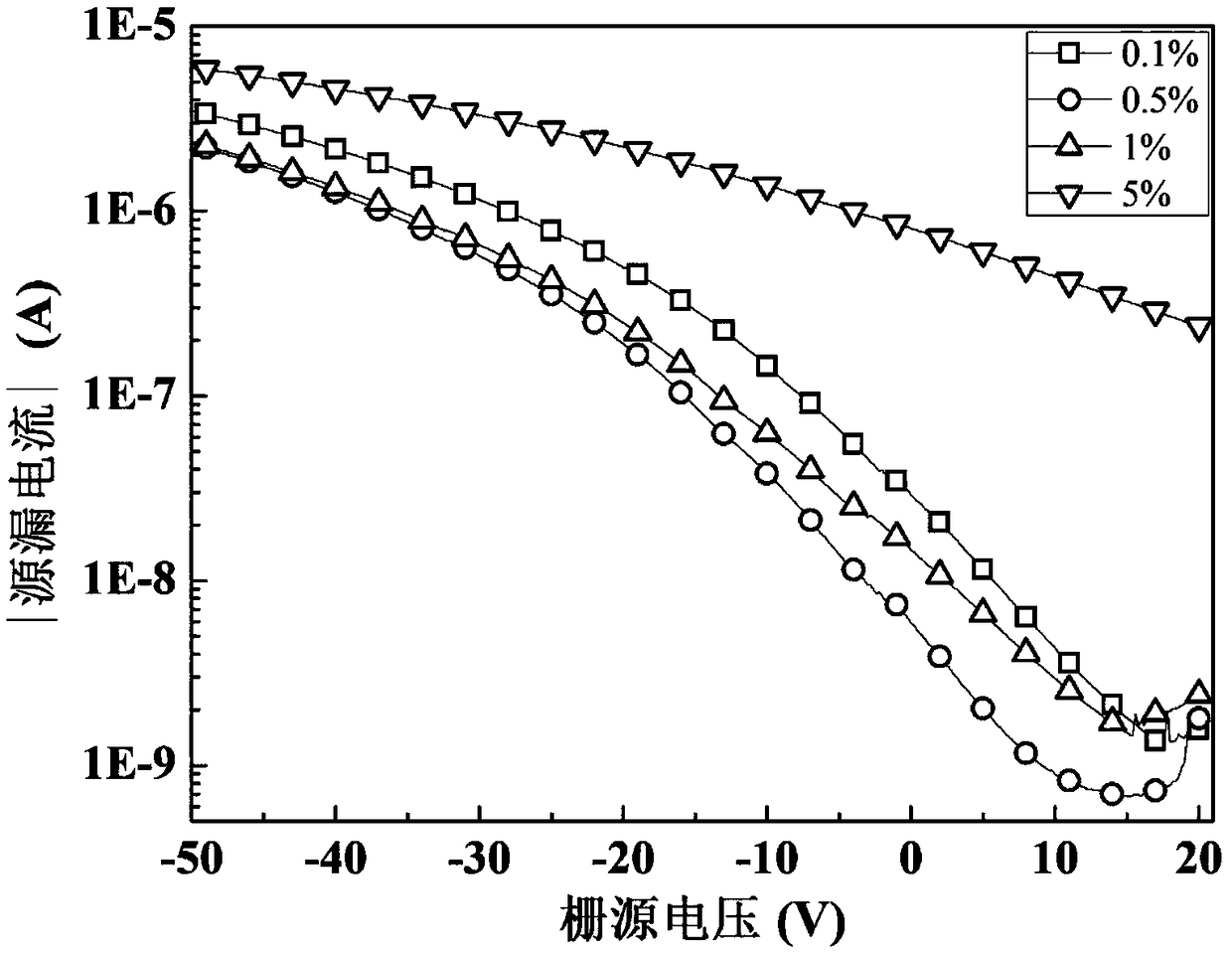

[0023] 1.1. Preparation of precursor solution for nickel-doped copper oxide film

[0024] Select glycerol and deionized water, prepare a mixed solution at a volume ratio of 1:1-4, then take nickel nitrate and copper nitrate and dissolve them in the mixed solution at a molar ratio of 1-5:999-95, and configure 0.1 mol / L concentration of the precursor solution, stirred by magnetic force for 6-12 hours; to obtain the precursor solution of the nickel-doped copper oxide film;

[0025] 1.2. Preparation of nickel-doped copper oxide film

[0026] Select a heavily doped silicon wafer as the substrate, wash it with acetone: time, 20 minutes; wash with deionized water: time, 20 minutes; wash with ethanol: time, 20 minutes; place in an annealing furnace for annealing treatment: preheat Time, 20 minutes, preheating temperature, 600 ℃;

[0027] Spin-coat th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com