Preparation method of composite photocatalyst TiO2/g-C3N4 derived from MOF (Metal Organic Frameworks)

A technology of g-c3n4 and composite light is applied in the field of materials to achieve the effects of environmental friendliness, widening space distance and good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

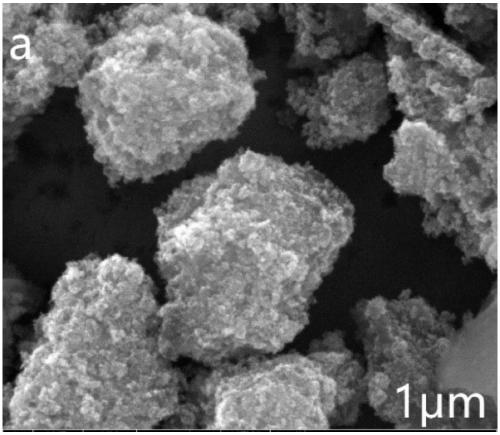

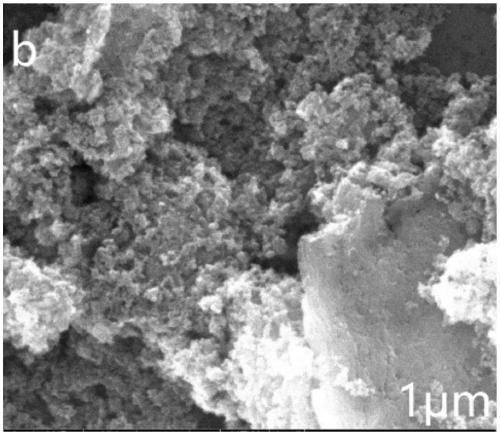

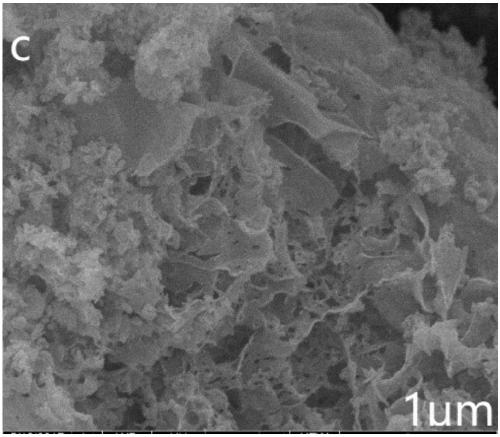

Image

Examples

Embodiment 1

[0032] Measure 0.39ml of tetrabutyl titanate, 13.5ml of dimethylformamide, 1.5ml of ethanol, weigh 1.5g of terephthalic acid, sonicate the above raw materials for 10min, then mix and stir at room temperature for 1h to form a uniform mixture ;Put the above mixed solution into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 160°C for 24 hours. After natural cooling, remove the supernatant, wash with terephthalic acid and absolute ethanol three times, and dry in an oven at 60°C 5h, the resulting product is MIL-125.

[0033]Weigh 500mg of MIL-125 and 100mg of melamine and place them in an agate mortar for full grinding and mixing for 10 minutes; put the evenly mixed mixture of MIL-125 and melamine into a crucible, then put it into a muffle furnace for heat treatment, and the heating program is : From room temperature to 500°C with a heating rate of 5°C / min, and keep it warm for 2h, then cool with the furnace, and the whole heat treatment process is carried o...

Embodiment 2

[0036] Measure 0.39ml of tetrabutyl titanate, 13.5ml of dimethylformamide, 1.5ml of ethanol, weigh 1.5g of terephthalic acid, sonicate the above raw materials for 10min, then mix and stir at room temperature for 1h to form a uniform mixture ;Put the above mixed solution into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 160°C for 24 hours. After natural cooling, remove the supernatant, wash with terephthalic acid and absolute ethanol three times, and dry in an oven at 60°C 5h, the resulting product is MIL-125;

[0037] Weigh 500mg MIL-125 and 200mg melamine and place them in an agate mortar for full grinding and mixing for 10 minutes; put the evenly mixed MIL-125 and melamine mixture into a crucible, then put it into a muffle furnace for heat treatment, and the heating program is : From room temperature to 500°C with a heating rate of 5°C / min, and keep it warm for 2h, then cool with the furnace, and the whole heat treatment process is carried out under...

Embodiment 3

[0040] Measure 0.39ml of tetrabutyl titanate, 13.5ml of dimethylformamide, 1.5ml of ethanol, weigh 1.5g of terephthalic acid, sonicate the above raw materials for 10min, then mix and stir at room temperature for 1h to form a uniform mixture ;Put the above mixed solution into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 160°C for 24 hours. After natural cooling, remove the supernatant, wash with terephthalic acid and absolute ethanol three times, and dry in an oven at 60°C 5h, the resulting product is MIL-125.

[0041] Weigh 500mg MIL-125 and 375mg melamine and place them in an agate mortar for full grinding and mixing for 10 minutes; put the evenly mixed MIL-125 and melamine mixture into a crucible, then put it in a muffle furnace for heat treatment, and the heating program is : From room temperature to 500°C with a heating rate of 5°C / min, and keep it warm for 2h, then cool with the furnace, and the whole heat treatment process is carried out under a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com