Core-shell type composite micro-nanoparticles and preparation method thereof

A micro-nano particle, core-shell technology, used in chemical instruments and methods, special compound water treatment, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of high temperature operation, harsh conditions, and complexity. Achieve the effects of mild reaction conditions, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

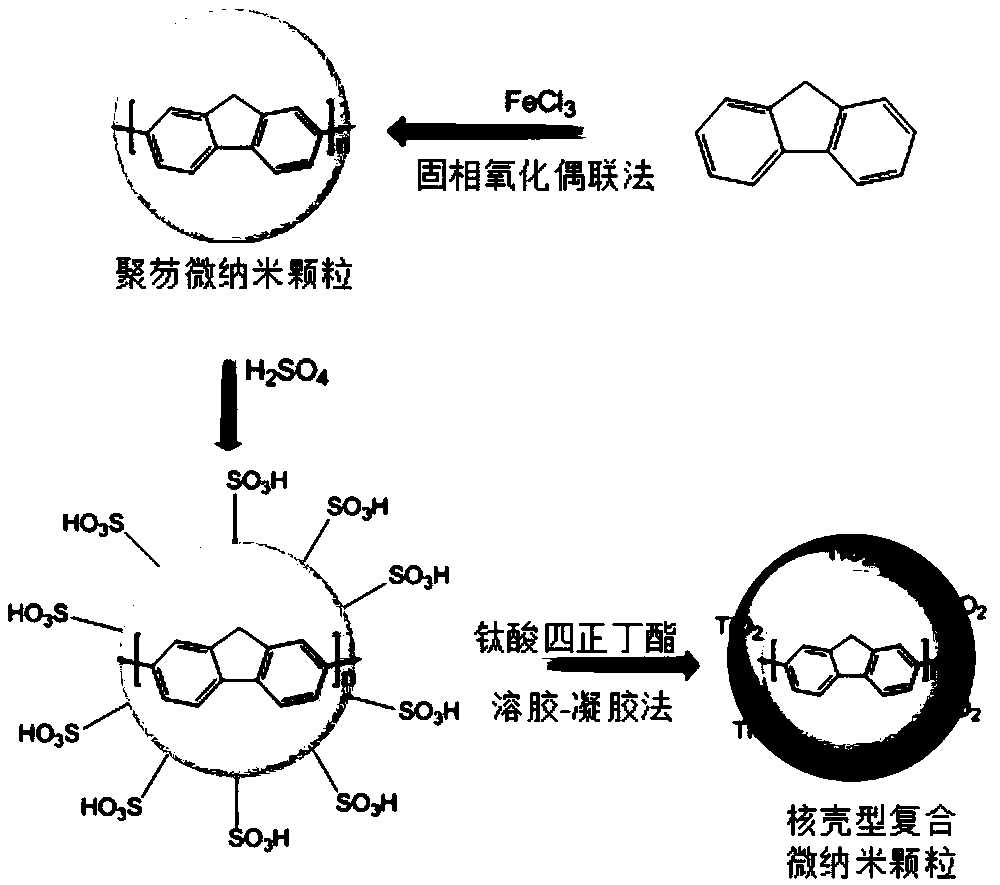

[0022] A method for preparing core-shell composite micro-nano particles, using fluorene monomers as raw materials, preparing polyfluorene micro-nano particles through a solid-phase oxidation coupling method; performing a sulfonation reaction of the polyfluorene micro-nano particles with concentrated sulfuric acid , to obtain sulfonated micro-nano particles; the sulfonated micro-nano particles and tetra-n-butyl titanate are sequentially subjected to adsorption and hydrolysis reactions to obtain the core-shell type composite micro-nano particles.

[0023] Reaction principle: Polyfluorene micronanoparticles can undergo sulfonation reaction in concentrated sulfuric acid, grafted with sulfonic acid groups, polyfluorene micronanoparticles with sulfonic acid groups can adsorb tetra-n-butyl titanate, tetra-n-titanate Butyl esters can be hydrolyzed to TiO 2 ,TiO 2 Coating on the surface of polyfluorene micro-nano particles forms core-shell micro-nano particles.

[0024] It can be see...

Embodiment 1

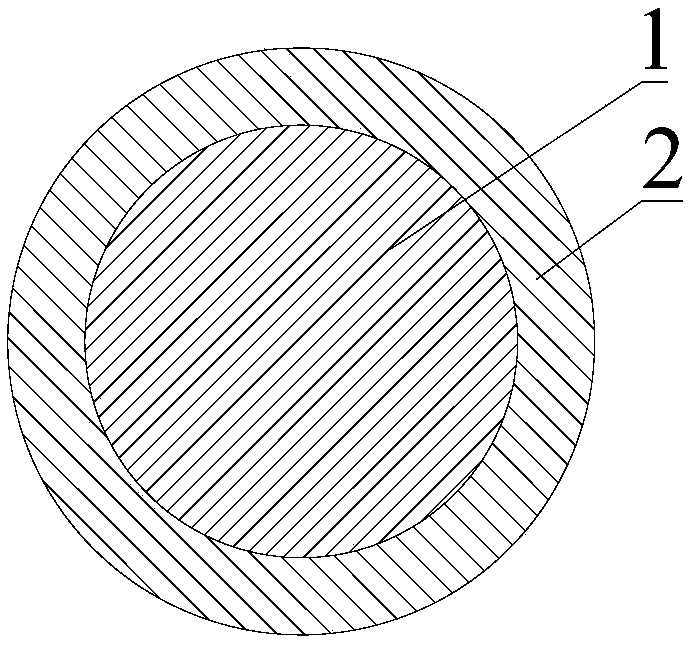

[0040] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0041] A core-shell type composite micro-nano particle, comprising an inner core layer 1 and a shell layer 2, the shell layer 2 is a titanium dioxide layer, the inner core layer 1 is a polyfluorene layer, the core-shell type composite micro-nano particle The particle size is 5-10 μm.

Embodiment 2

[0043] Please refer to figure 2 , Embodiment 2 of the present invention is a method for preparing core-shell composite micro-nano particles, comprising the following steps:

[0044] Step 1: Put 0.83g (5mmol) fluorene and 3.24g (20mmol) anhydrous ferric chloride into a glass mortar, grind with a pestle for half an hour at room temperature, and then wash the mixture with 5% hydrochloric acid ethanol solution , filtered and dried to obtain a crude product, and then extracted with absolute ethanol to obtain polyfluorene micro-nano particles.

[0045]Step 2: sulfonating the polyfluorene micro-nano particles with concentrated sulfuric acid to obtain sulfonated micro-nano particles. Specifically: first disperse polyfluorene micro-nano particles in absolute ethanol by ultrasonic dispersion, and then add concentrated sulfuric acid for sulfonation reaction. The time of the ultrasonic dispersion is at least 10 minutes, and the temperature of the sulfonation reaction is 40 ℃, the time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com