Preparation of an immobilized microalgae water quality regulator

A regulating agent and microalgae technology, which is applied in the field of preparation of immobilized microalgae water quality regulating agent, can solve the problems of high manual management fee, high cost, secondary pollution, etc., reduce pollution, prolong storage time, and realize effective utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation of immobilized microalgae water quality control agent, comprises the following steps:

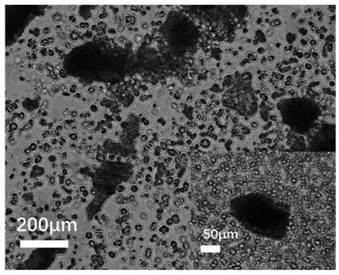

[0028] (1) The shells are puffed in a vacuum tube furnace at 600°C for 2 hours, polished and crushed to the nanometer level; the high-temperature puffed shells become a kind of biochar, which is a new type of environmental functional material with developed pore structure and huge The specific surface area can not only absorb heavy metals and organic pollutants in wastewater, but also be used as a microbial carrier; shell powder with nanometer size is an excellent carrier;

[0029] (2) Mix shell powder with 30mL of 1% potassium carbonate solution, which contains 3% nicotinamide and 0.5% phenyl n-butyl ether in mass concentration, after hydrothermal modification at 160°C for 24h Suction filtration and drying, set aside; weakly alkaline potassium carbonate solution can be mixed with CaO, SiO in shell powder 2and other components react to form soluble salts, which...

Embodiment 2

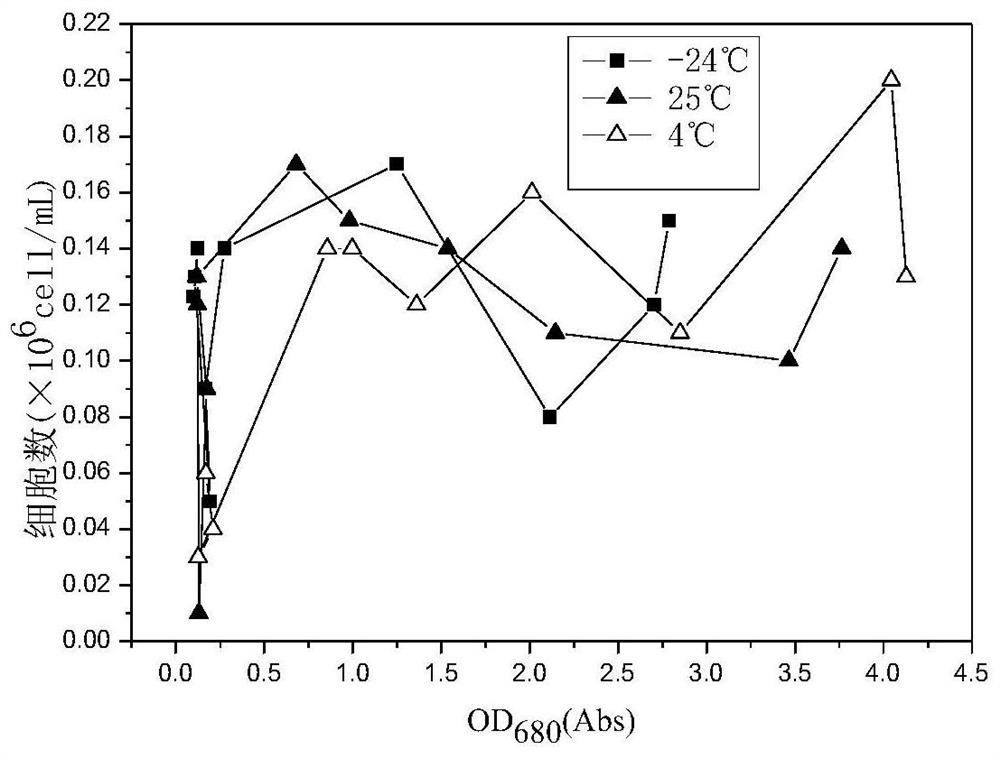

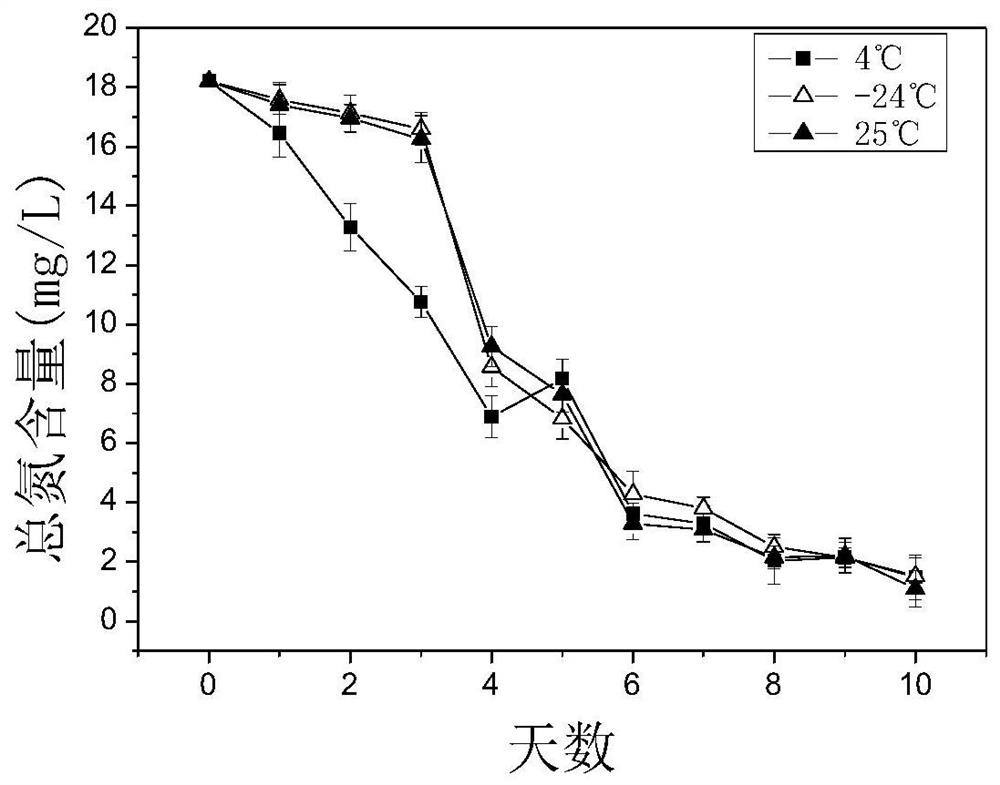

[0033] The shells were puffed in a vacuum tube furnace at 600°C for 2 hours, ground and crushed to the nanoscale; 30 mL of 1% potassium carbonate solution was used as a modifier, and the potassium carbonate solution contained 3% nicotinamide and 0.5 % phenyl n-butyl ether, hydrothermally modified shell powder at 160°C for 24 hours, then suction-filtered and dried, and set aside; mixed L-amino acid with shell powder, added L-mannitol and chlorogenic acid, and ultrasonicated at 60°C for 30 minutes. Centrifuge, wash with water until neutral, and then vacuum-dry the solid solute for 24 hours; the mass ratio of L-amino acid to shell powder is 1:1, and the L-amino acid is arginine and lysine, and the mass ratio of the two is 1:2. The volume of mixed equal volumes of mannitol and chlorogenic acid is 50mL; take 100mL of chlorella culture solution grown in the logarithmic growth phase, add 0.2g of shell powder, 20mL of tea extract, 0.5g of sodium alginate and 2mL of 3% Glycerol is mixe...

Embodiment 3

[0035] The shells were puffed in a vacuum tube furnace at 600°C for 2 hours, ground and crushed to the nanoscale; 30 mL of 1% potassium carbonate solution was used as a modifier, and the potassium carbonate solution contained 3% nicotinamide and 0.5 % phenyl n-butyl ether, hydrothermally modified shell powder at 160°C for 24 hours, then suction-filtered and dried, and set aside; mixed L-amino acid with shell powder, added L-mannitol and chlorogenic acid, and ultrasonicated at 60°C for 30 minutes. Centrifuge, wash with water until neutral, and then vacuum-dry the solid solute for 24 hours; the mass ratio of L-amino acid to shell powder is 1:1, and the L-amino acid is arginine and lysine, and the mass ratio of the two is 1:2. The volume of mixed equal volumes of mannitol and chlorogenic acid is 50mL; take 100mL of chlorella culture solution grown in the logarithmic growth phase, add 0.2g of shell powder, 20mL of tea extract, 0.5g of sodium alginate and 2mL of 3% Glycerol is mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com