Kitchen waste percolate enhanced treatment method and system

A technology for enhanced treatment of food waste, applied in filtration treatment, contaminated groundwater/leachate treatment, anaerobic digestion treatment, etc., can solve the problems of large footprint, oil resistance, high operating cost, etc., to achieve increased Microbial attachment area, increased mud-water contact, and improved removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

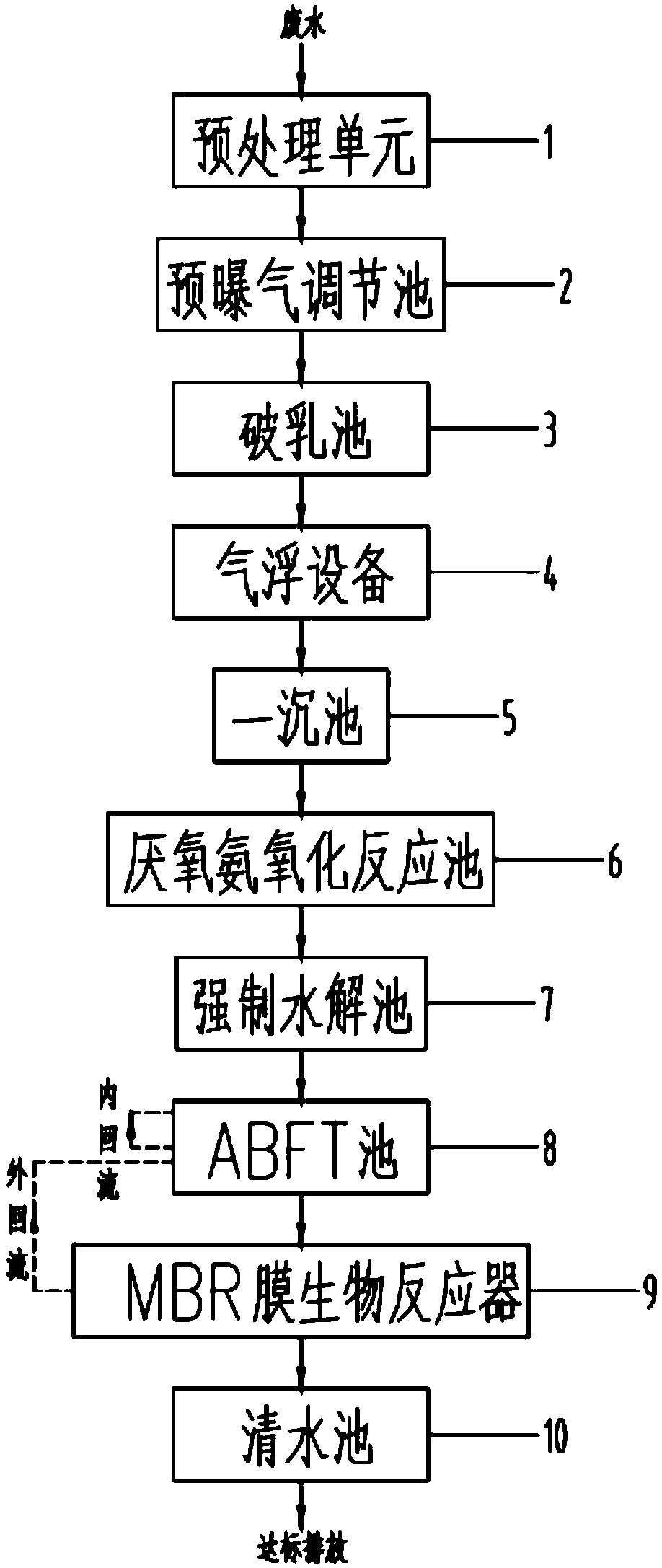

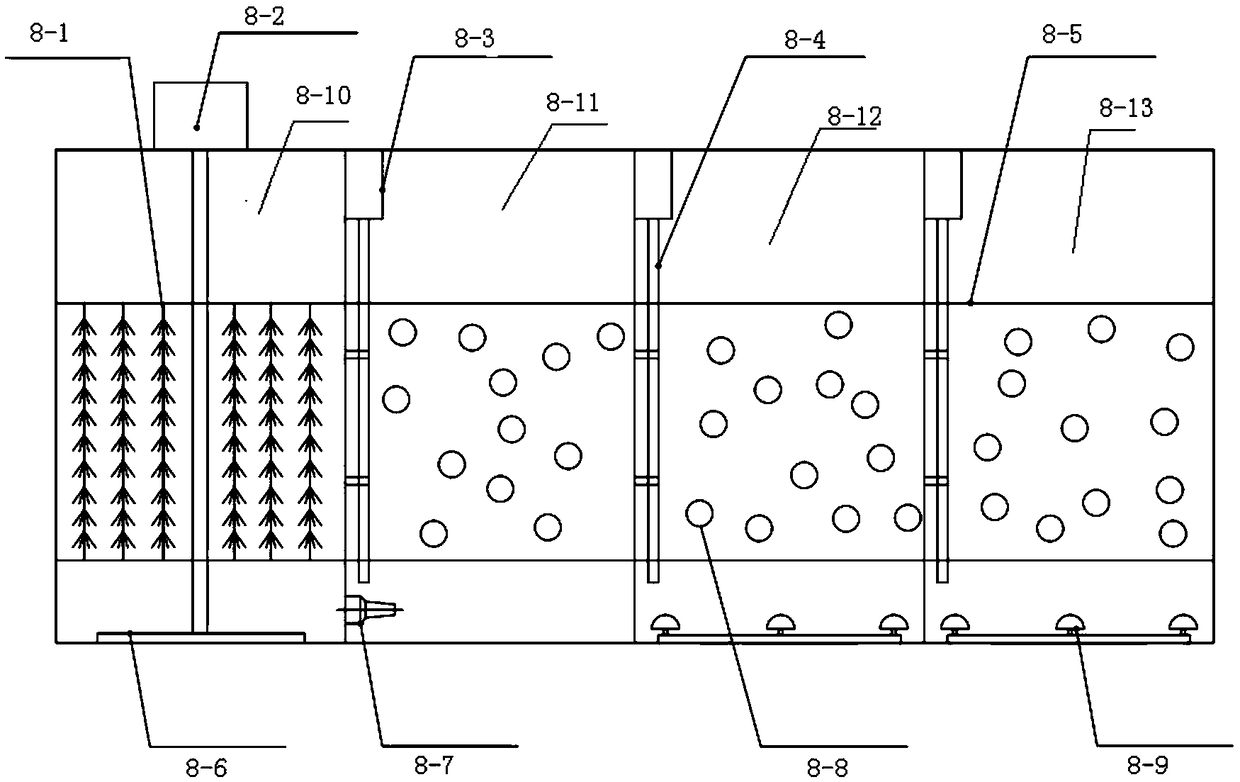

[0034] Embodiment 1 Food waste leachate enhanced treatment system

[0035] like Figure 1-2 The food waste leachate enhanced treatment system shown is mainly composed of a pretreatment unit (1), a pre-aeration adjustment tank (2), a demulsification tank (3), and an air flotation device (4) connected in sequence through pipelines. , a settling tank (5), anaerobic ammonium oxidation reaction tank (6), forced hydrolysis tank (7), ABFT tank (8), MBR membrane bioreactor (9), clear water tank (10). The pretreatment unit (1) includes a grille and a grease trap connected in sequence by pipelines, the forced hydrolysis tank (7) includes a hydrolysis acidification tank, and a pulse water distribution system is set on the hydrolysis acidification tank; in the food waste leachate enhanced treatment system Backflow is provided: a backflow pipe is arranged between the aerobic pool and the anoxic pool in the ABFT pool (8), and a backflow pipe is arranged between the MBR membrane bioreactor ...

Embodiment 2

[0037] Embodiment 2 Kitchen garbage leachate treatment

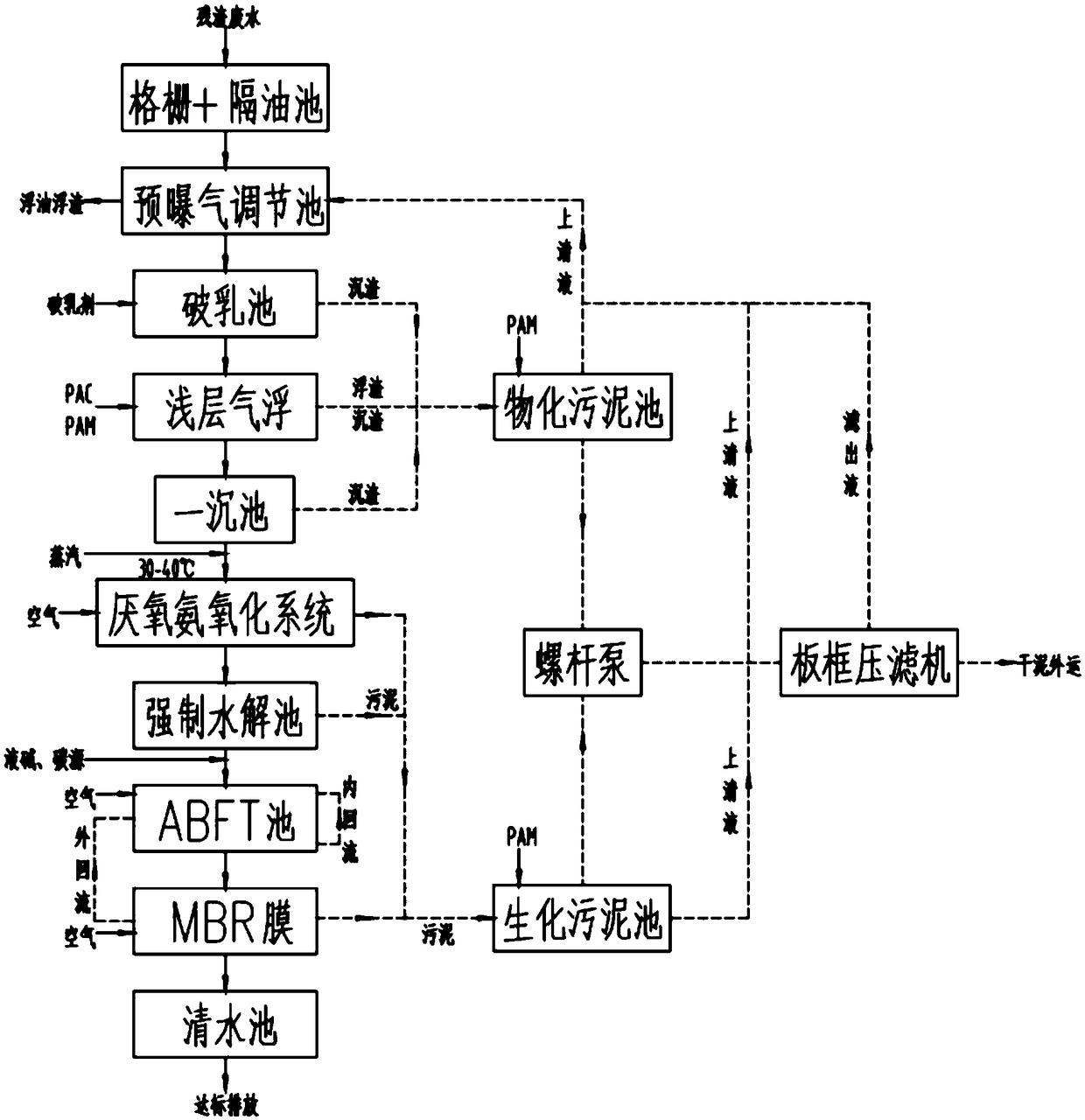

[0038]Adopt the system of embodiment 1 to carry out kitchen garbage leachate wastewater treatment, operate according to the following steps, its process flow chart is as follows image 3 Shown:

[0039] (1) Kitchen garbage leachate wastewater enters the grille, grease trap, and pre-aeration regulating tank in turn: the grille adopts three-stage grille to remove large scum in the wastewater, and then enters the grease trap, using three-stage traps Oil pool, to isolate slick oil, scum and grease in wastewater. Since the wastewater discharge cycle is uncertain, the pre-aeration adjustment tank is used to uniform the water volume and water quality, and the perforated aeration is set in the pre-aeration adjustment tank to stir the wastewater to prevent solid particles from settling and cooling down. The hydraulic retention time of wastewater in the grid, grease trap and pre-aeration regulating tank is 28 hours in total. Th...

Embodiment 3

[0051] Adopt the method for embodiment 2 to carry out kitchen garbage leachate treatment: kitchen garbage leachate 300m 3 / d, influent water quality COD: 12000mg / l, SS: 14000mg / l, ammonia nitrogen: 2000mg / l, total nitrogen: 2500mg / l, animal and vegetable oil: 800mg / l, pH: 7-9, through the method of embodiment 1 After treatment, the effluent reaches the second-level standard in Table 4 of the "Integrated Wastewater Discharge Standard" (GB8978-1996).

[0052] Demonstration of pretreatment process selection: Waste water first enters the grid oil separation adjustment tank to remove scum in the waste water, the oil separation tank isolates the floating oil in the water, the water quality of the pre-aeration adjustment tank is homogeneous, and the solid suspended matter of the wastewater: 14000mg / l, animal and vegetable oil: 800mg / l, the waste water is treated with demulsification + shallow air flotation, not only can remove most of the suspended matter, dispersed oil and emulsifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com