Method for producing butanol by utilizing efficient fermentation of pichia pastoris solid waste

A Pichia pastoris and waste technology, applied in microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve problems such as cannot be simply discarded/discharged, and achieve the effect of saving consumption and improving economic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

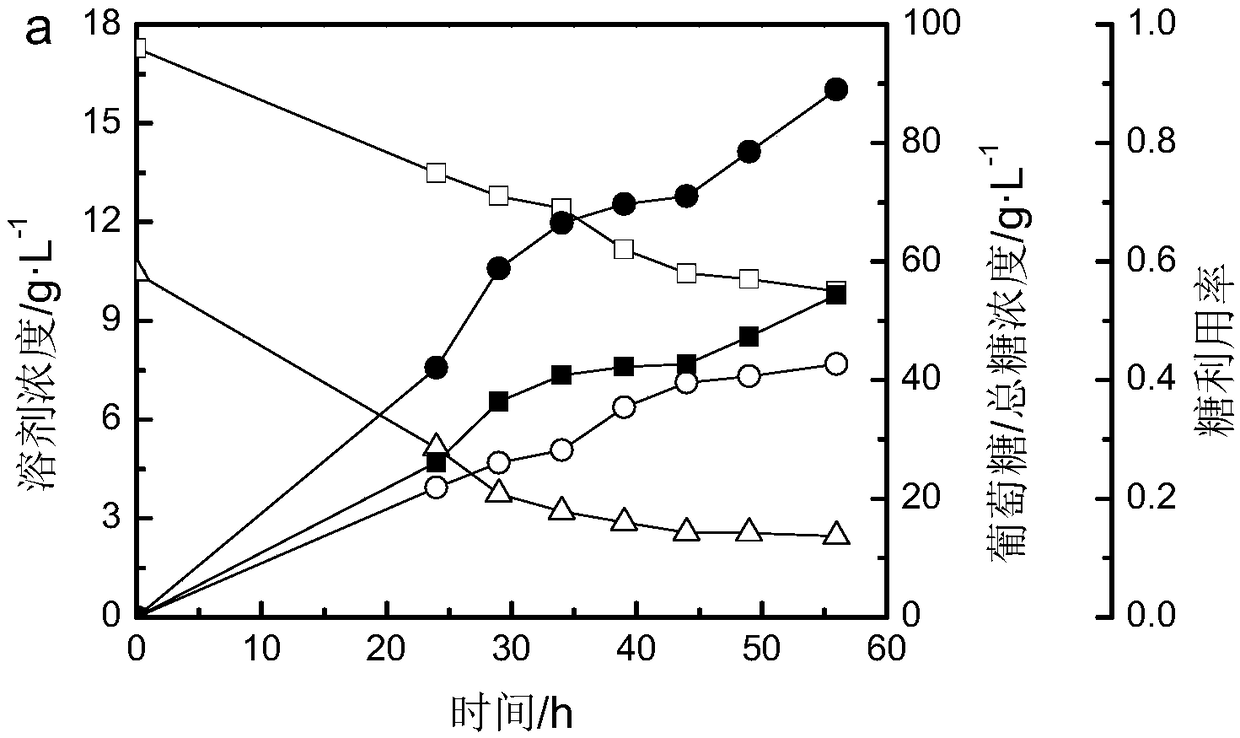

[0111] Embodiment 1: 7L static anaerobic fermenter fermentation

[0112] ABE fermentation was carried out in 15% corn flour medium on 7L tanks.

[0113] Fermentation 56h finishes, butanol concentration, ABE total concentration, total sugar utilization rate and total residual sugar concentration are respectively 9.78g / L, 15.72g / L, 43%, 55.00g / L (ABE fermentation performance see figure 1 ).

Embodiment 2

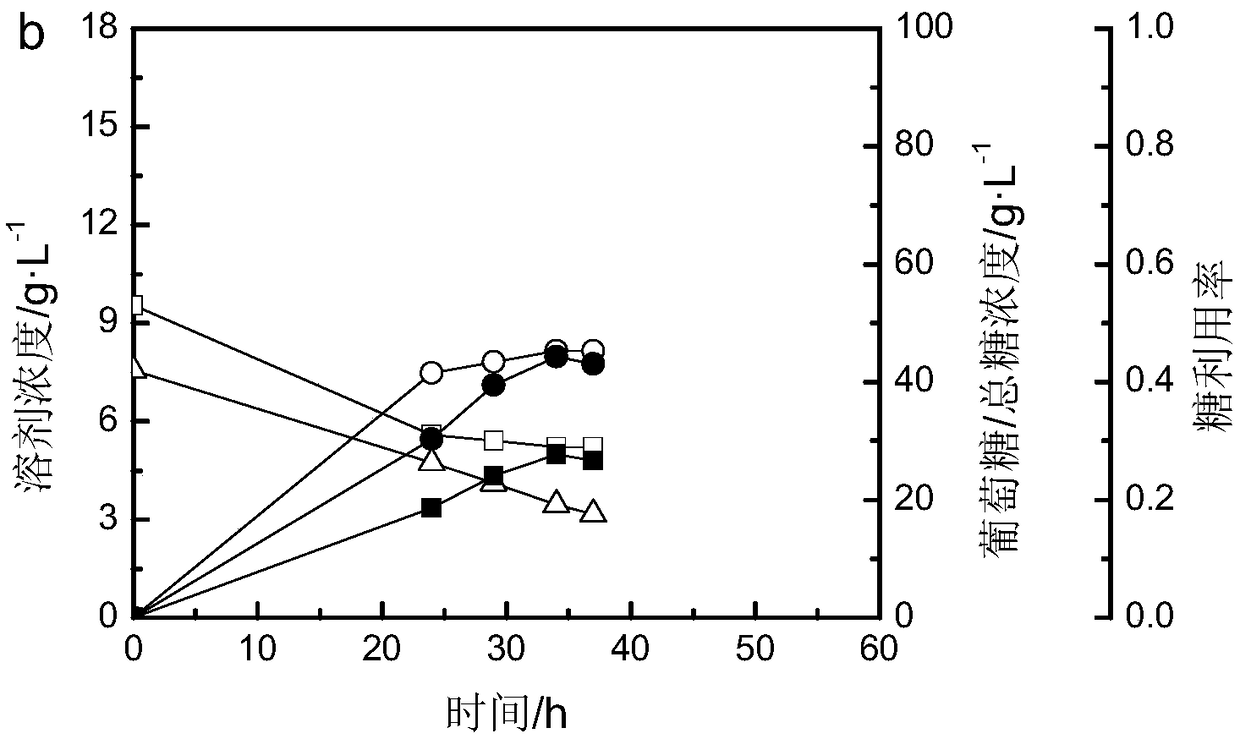

[0114] Embodiment 2: 7L static anaerobic fermenter fermentation

[0115] ABE fermentation was carried out on 7L tanks with 8% corn flour medium.

[0116] Fermentation 37h finishes, butanol concentration, ABE total concentration, total sugar utilization rate and total residual sugar concentration are respectively 4.79g / L, 7.75g / L, 45%, 17.60g / L (ABE fermentation performance see figure 2 , two For the changes of sugar / trisaccharide and total amino acid concentration, see Figure 5 ).

Embodiment 3

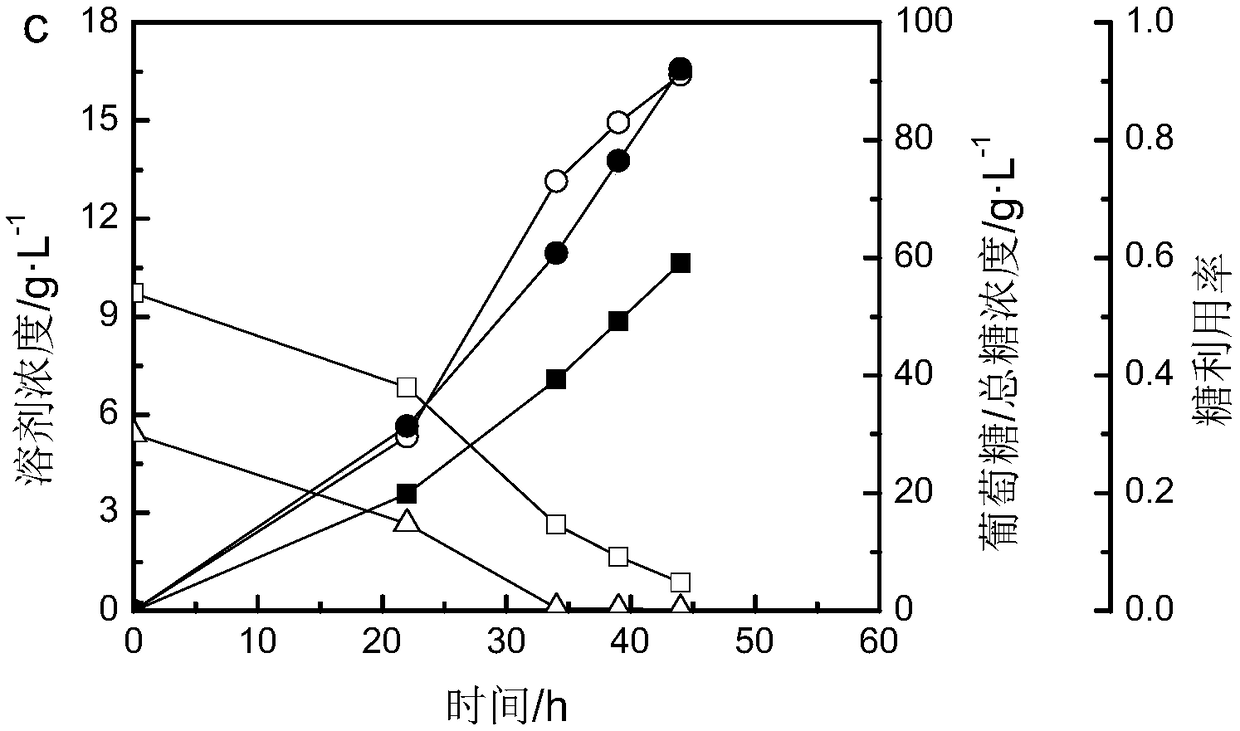

[0117] Embodiment 3: 7L static anaerobic fermenter fermentation

[0118] Carry out ABE fermentation with 8% corn flour medium on the 7L tank, the specification of waste Pichia treatment liquid is yeast content 400g / L, NaOH consumption 50g / L (after adjusting pH, SO 4 2- 58g / L), at the beginning of the solvent production period, after the pH bottomed out and rebounded to 0.1-0.2, 0.75L of the above-mentioned waste Pichia treatment solution was added, and the treatment solution was diluted 5 times, and the final total liquid volume was 3.75L. Cornmeal (actual) content, waste yeast content and SO in mixed stock 4 2- The contents were 6.4g / L, 80g / L, and 11.6g / L respectively (the average value was taken after 3 batches of fermentation using Pichia pastoris solid waste A).

[0119] Fermentation 44h finishes, butanol concentration, ABE total concentration, total sugar utilization rate and total residual sugar concentration are respectively 10.63g / L, 16.57g / L, 91%, 4.80g / L (ABE ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com