Flexible three-dimensional porous nitrogen-doped carbon nanotube/cobalt phosphide composite material and preparation method and application thereof

A three-dimensional porous, nitrogen-doped carbon technology, applied in the direction of electrode shape/type, electrode, electrolysis process, etc., can solve the problems of reducing the active number of electrocatalysts, prone to agglomeration, weakening the catalytic performance of hydrogen evolution, etc., to achieve excellent hydrogen evolution catalysis Performance, Simplified Implementation Process, Excellent Cycling Stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Provides a flexible three-dimensional porous nitrogen-doped carbon nanotube / cobalt phosphide composite material prepared according to the method of the present invention

[0035] Cut a piece of melamine sponge of 5 cm × 3 cm × 2 cm, ultrasonically clean it with ethanol for 15 min, and dry at 60°C; weigh 60 parts of 2-methylimidazole and 20 parts of cobalt nitrate hexahydrate, dissolve them in 20 parts of methanol respectively, and dissolve the above Mix the two solutions, ultrasonically disperse for 10 minutes, and at the same time put in a melamine sponge to fully impregnate and evenly absorb and then dry. Transfer the dried compound to an alumina ark crucible, place it in a tube furnace, and under the protection of Ar atmosphere, at 350 ° C Use 30 parts of sodium hypophosphite in the upper tuyere, phosphating by thermal decomposition and vapor deposition, and continue to heat up, carbonize at 700 ° C, cool to room temperature and place in a sample box for...

Embodiment 2

[0038]Cut a piece of melamine sponge of 5 cm × 3 cm × 2 cm, ultrasonically clean it with ethanol for 15 min, and dry at 60°C; weigh 60 parts of 2-methylimidazole and 20 parts of cobalt nitrate hexahydrate, dissolve them in 20 parts of methanol respectively, and dissolve the above Mix the two solutions, ultrasonically disperse for 10 minutes, and at the same time put in a melamine sponge to fully impregnate and evenly absorb and then dry. Transfer the dried compound to an alumina ark crucible, place it in a tube furnace, and under the protection of Ar atmosphere, at 350 ° C Use 30 parts of sodium hypophosphite to place in the upper tuyere, phosphating by thermal decomposition and vapor deposition, and continue to heat up, carbonize at 800 ° C, cool to room temperature and place in a sample box for collection.

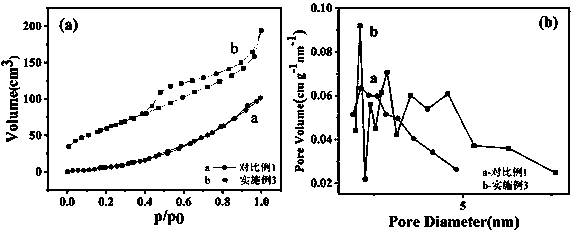

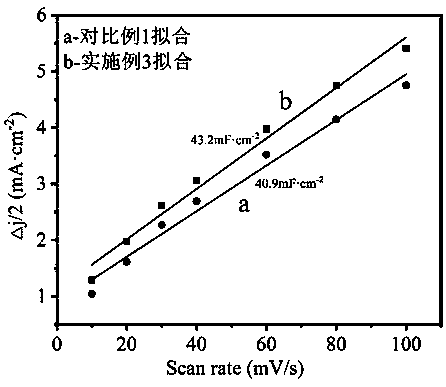

[0039] The obtained flexible three-dimensional porous nitrogen-doped carbon nanotubes / cobalt phosphide composite has a specific surface area of 180.8 m 2 g -1 , with ...

Embodiment 3

[0041] Cut a piece of melamine sponge of 5 cm × 3 cm × 2 cm, ultrasonically clean it with ethanol for 15 min, and dry at 60°C; weigh 60 parts of 2-methylimidazole and 20 parts of cobalt nitrate hexahydrate, dissolve them in 20 parts of methanol respectively, and dissolve the above Mix the two solutions, ultrasonically disperse for 10 minutes, and at the same time put in a melamine sponge to fully impregnate and evenly absorb and then dry. Transfer the dried compound to an alumina ark crucible, place it in a tube furnace, and under the protection of Ar atmosphere, at 350 ° C Use 30 parts of sodium hypophosphite in the upper tuyere, phosphating by thermal decomposition and vapor deposition, and continue to heat up, carbonize at 900 ° C, cool to room temperature and place in a sample box for collection.

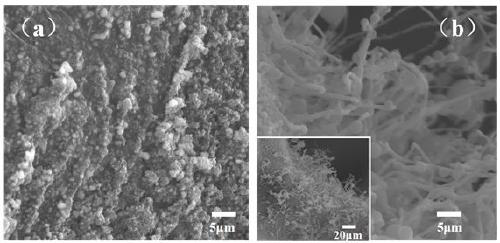

[0042] The resulting flexible three-dimensional porous nitrogen-doped carbon nanotubes / cobalt phosphide composites exhibit a unique structure in which carbon nanotubes are compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com