Pig farming wastewater treatment method based on biomembrane

A technology for aquaculture wastewater and treatment methods, which is applied in biological water/sewage treatment, animal husbandry wastewater treatment, water/sewage treatment, etc., can solve the problems of poor separation effect, unstable operation, low treatment efficiency, etc., and saves infrastructure. The effect of investment, speeding up the governance process, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

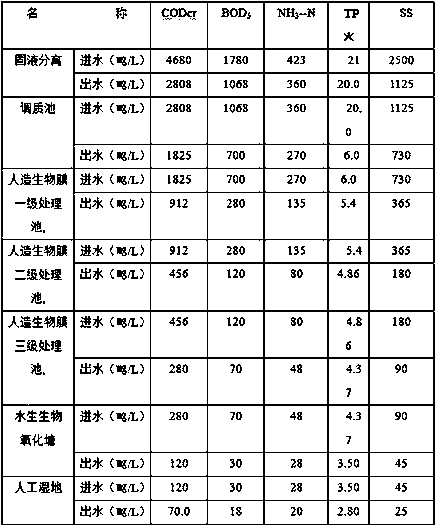

Embodiment 1

[0036] A biofilm-based method for treating pig breeding wastewater is characterized in that it comprises the following steps:

[0037] S1. Send aquaculture wastewater to a biogas digester for anaerobic fermentation; decompose pollutants to produce biogas, which is reused as energy.

[0038] S2. Collect the biogas slurry and biogas residue after biogas fermentation into the collection tank, and then separate the solid and liquid;

[0039] S3. The biogas residue after solid-liquid separation is processed into bio-organic fertilizer; it is used in farmland to save agricultural fertilizer expenditure.

[0040] S4. The biogas slurry enters the sedimentation tank to further remove the fine suspended solids; the solids are manually cleaned up regularly for use as fertilizer.

[0041] Among them, S3 and S4 are performed simultaneously;

[0042] S5. Through the sewage photocatalytic water bridge oxidation sloping plate, the sewage from the sedimentation tank is oxidized by sunlight through photoc...

Embodiment 2

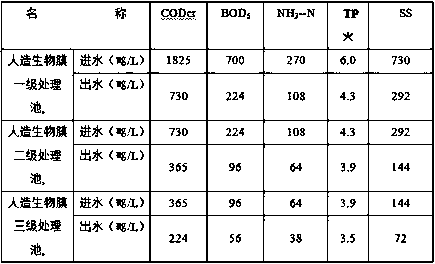

[0063] This embodiment adopts the same biofilm-based pig breeding wastewater treatment method as in embodiment 1, except that in step S8, the artificial biofilm includes the following components by weight: hydroxymethyl Cellulose 20, sodium alginate 16, polyvinyl alcohol 13, graphene particles 33, molecular sieve 55, straw fibers 18, plant endophytes 9. The molecular sieve is any molecular sieve with strong adsorption in the prior art, and the plant endophyte is an anaerobic microbial plant endophyte in the prior art.

[0064] In the present invention, the preparation method of the biofilm is: preparing polyvinyl alcohol into a fibrous shape, and knitting hydroxymethyl cellulose, straw fibers, and polyvinyl alcohol fibers through warp knitting or weft knitting in weaving. Form a spatial network structure, and then fill the pores of the network structure with sodium alginate, graphene particles, molecular sieves, and plant endophytes, and heat to soften the fibers in the spatial n...

Embodiment 3

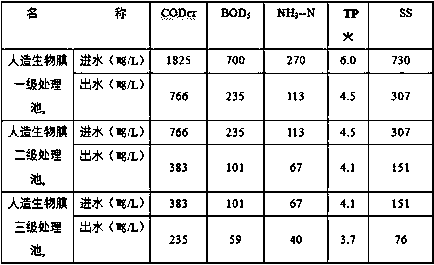

[0067] This embodiment adopts the same biofilm-based pig breeding wastewater treatment method as in embodiment 1, except that in step S8, the artificial biofilm includes the following components by weight: hydroxymethyl Cellulose 35, sodium alginate 24, polyvinyl alcohol 25, graphene particles 42, molecular sieve 83, straw fiber 29, plant endophyte 17. The molecular sieve is any molecular sieve with strong adsorption in the prior art, and the plant endophyte is the aerobic microbial plant endophyte in the prior art.

[0068] In the present invention, the preparation method of the biofilm is: preparing polyvinyl alcohol into a fibrous shape, and knitting hydroxymethyl cellulose, straw fibers, and polyvinyl alcohol fibers through warp knitting or weft knitting in weaving. Form a spatial network structure, and then fill the pores of the network structure with sodium alginate, graphene particles, molecular sieves, and plant endophytes, and heat to soften the fibers in the spatial net...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com