Preparation method of ultra-high molecular weight polyethylene nano-composite material

A nano-composite material and ultra-high molecular weight technology, applied in the field of composite materials, can solve the problems of reinforcement, small particle size of nano-components, and difficulty in exerting nano-equivalents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

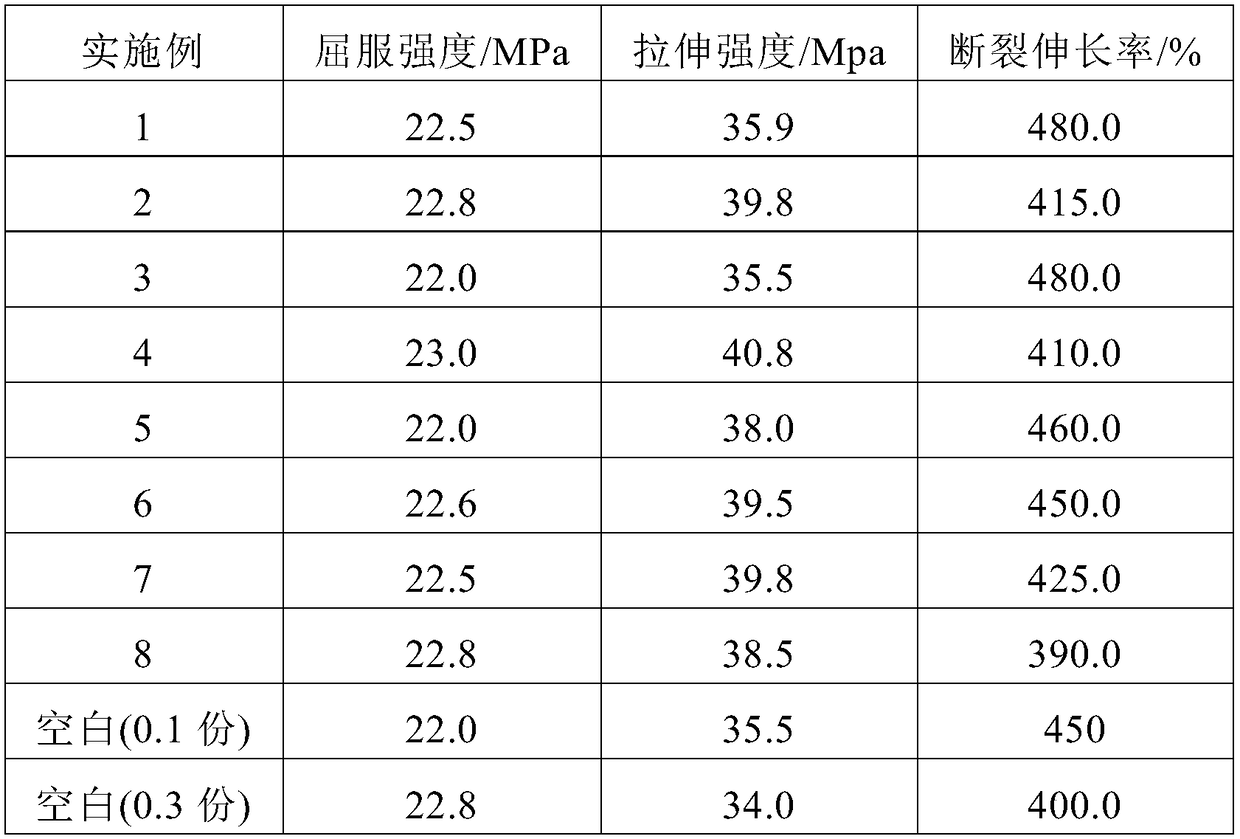

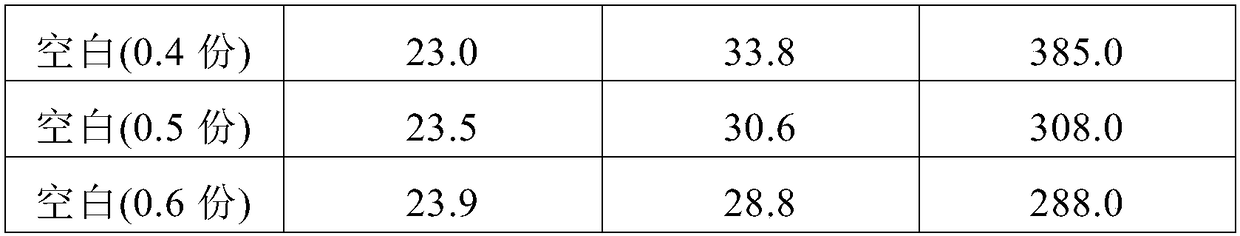

Examples

Embodiment 1

[0031] Nano-silica is first dispersed in the coupling agent treatment solution, the coupling agent is a silane coupling agent, the concentration of the coupling agent is 1%, the solvent is ethanol, stirred at room temperature for 8 minutes, filtered and dried; The nanomaterials are placed in an ethanol solution of acrylic acid, the monomer concentration is 25%, the initiator is benzophenone, the concentration is 1%, and the UV grafting reaction of the nanomaterials is realized by ultraviolet irradiation for 20 minutes under the protection of nitrogen, and then filtered and dried ; Disperse the grafted nanomaterials in a 0.5% ethanol solution of polyacrylamide, the specific gravity of the nanomaterials is 0.05%wt, and ultrasonically disperse for 10 minutes.

[0032]The ultra-high molecular weight polyethylene powder is dispersed in the nano-material solution treated with surfactant, the specific gravity of ultra-high molecular weight polyethylene is 100 parts, and the specific g...

Embodiment 2

[0035] Nano-silica is first dispersed in the coupling agent treatment solution, the coupling agent is a silane coupling agent, the concentration of the coupling agent is 5%, the solvent is ethanol, stirred at room temperature for 30 minutes, filtered and dried; The nanomaterials are placed in an ethanol solution of acrylic acid, the monomer concentration is 40%, the initiator is benzophenone, the concentration is 5%, and the ultraviolet grafting reaction of the nanomaterials is realized by ultraviolet irradiation for 20 minutes under the protection of nitrogen, and then filtered and dried ; Disperse the grafted nanomaterials in a 5% ethanol solution of polyacrylamide, the specific gravity of the nanomaterials is 0.25%wt, and ultrasonically disperse for 30 minutes.

[0036] The ultra-high molecular weight polyethylene powder is dispersed in the nano-material solution treated with surfactant. The specific gravity of the ultra-high molecular weight polyethylene is 100 parts, and t...

Embodiment 3

[0039] Nano-molybdenum disulfide is first dispersed in the coupling agent treatment solution, the coupling agent is a silane coupling agent, the concentration of the coupling agent is 1%, the solvent is acetone, stirred at room temperature for 8 minutes, filtered and dried; The nanomaterial is placed in an ethanol solution of methacrylic acid, the monomer concentration is 25%, the initiator is xanthone, and the concentration is 1%, and the ultraviolet grafting reaction of the nanomaterial is realized by ultraviolet irradiation for 20 minutes under the protection of nitrogen, and then filtered Drying; disperse the grafted nanomaterials in 0.5% ethanol solution of polyacrylamide, the specific gravity of the nanomaterials is 0.05%wt, and ultrasonically disperse for 10 minutes.

[0040] The ultra-high molecular weight polyethylene powder is dispersed in the nano-material solution treated with surfactant, the specific gravity of ultra-high molecular weight polyethylene is 100 parts,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap