Preparation of ionic liquid modified magnetic graphene oxide composite material and method for removing As(III) and As(V) in water

An ionic liquid and composite material technology, which is applied in the treatment of water samples containing arsenic (As), and the synthesis field of ionic liquid-modified magnetic graphene oxide composite materials, can solve the problems of poor adsorption effect, long time, difficult separation and the like, To achieve the effect of convenient recycling, short time and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

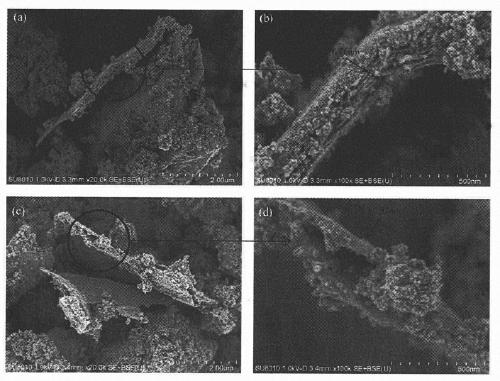

Embodiment 1

[0030] (1) Place a 500mL three-hole round bottom flask in a water bath at a temperature 2 SO 4 230mL with constant stirring. Then add 1.5g sodium nitrate NaNO 3 . Slowly add 5g of graphite powder and 35g of potassium permanganate successively. Mix and stir to make it fully dissolved for 2h. Then heated to 35°C, continued to stir for 2h, then slowly added 230mL of deionized water (45min), at this time the temperature rose naturally. The temperature was maintained at 98° C. for 2 h. Then remove the heat source and let it cool naturally. Pour the solution into a beaker, add 420 mL of deionized water and 2 mL of 30% H 2 o 2 . After standing overnight, suck out the supernatant, put the precipitate in a centrifuge tube, centrifuge (8000r / min, 5min) with a centrifuge, and then wash with dilute 10-fold hydrochloric acid until the supernatant does not react with sodium hydroxide. Formation of a black precipitate proves clean. After washing with acetone solution, it was dried...

Embodiment 2

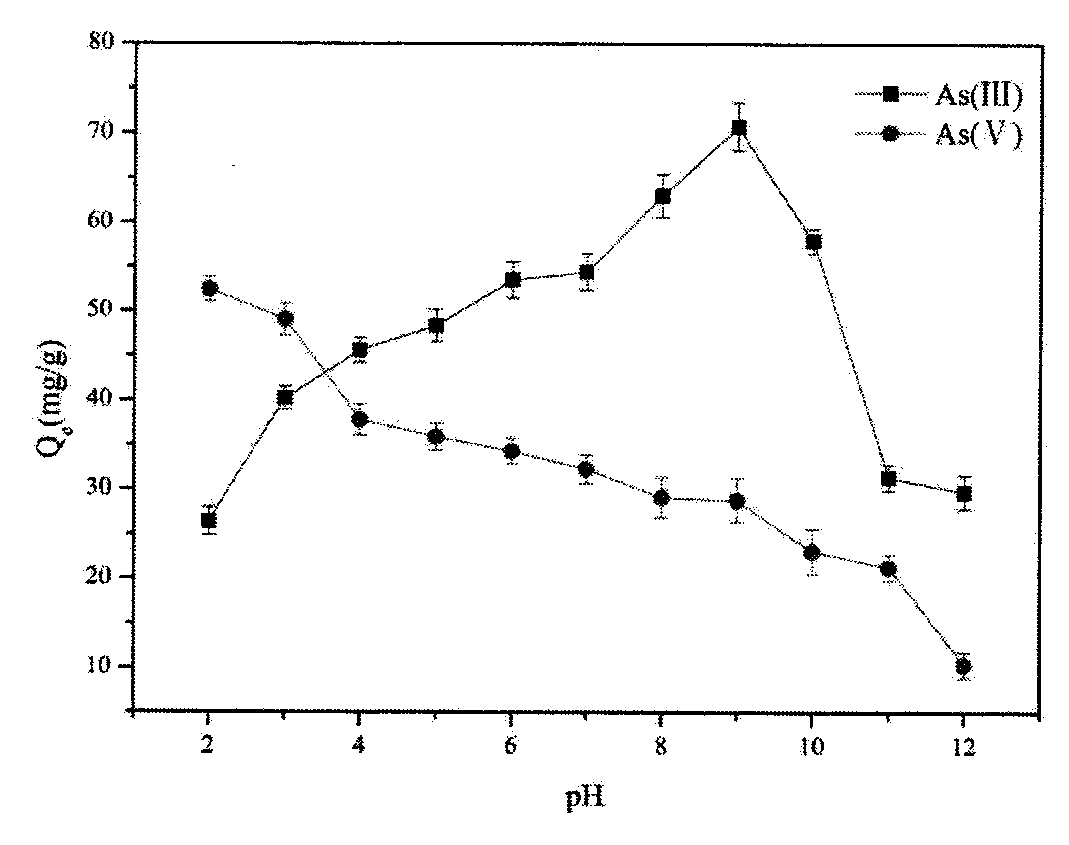

[0034] Under different initial solution pH values, the adsorption amount of As(III) and As(V) in the solution by the ionic liquid modified magnetic graphene oxide composite material was compared, and the specific steps were as follows:

[0035] 20 mg of the material obtained in Example 1 was added to 50 mL of solutions containing 50 mg / L As(III) and As(V) at different pH values, and the influence of pH value on the adsorption effect was investigated. The results show that the adsorption amount of As(III) is the largest at about pH 9, and the adsorption amount of As(V) is the largest at about pH 2. However, under strong acid and alkaline conditions, a small amount of Fe in the material will be precipitated, so the pH setting in the actual treatment for 7.

Embodiment 3

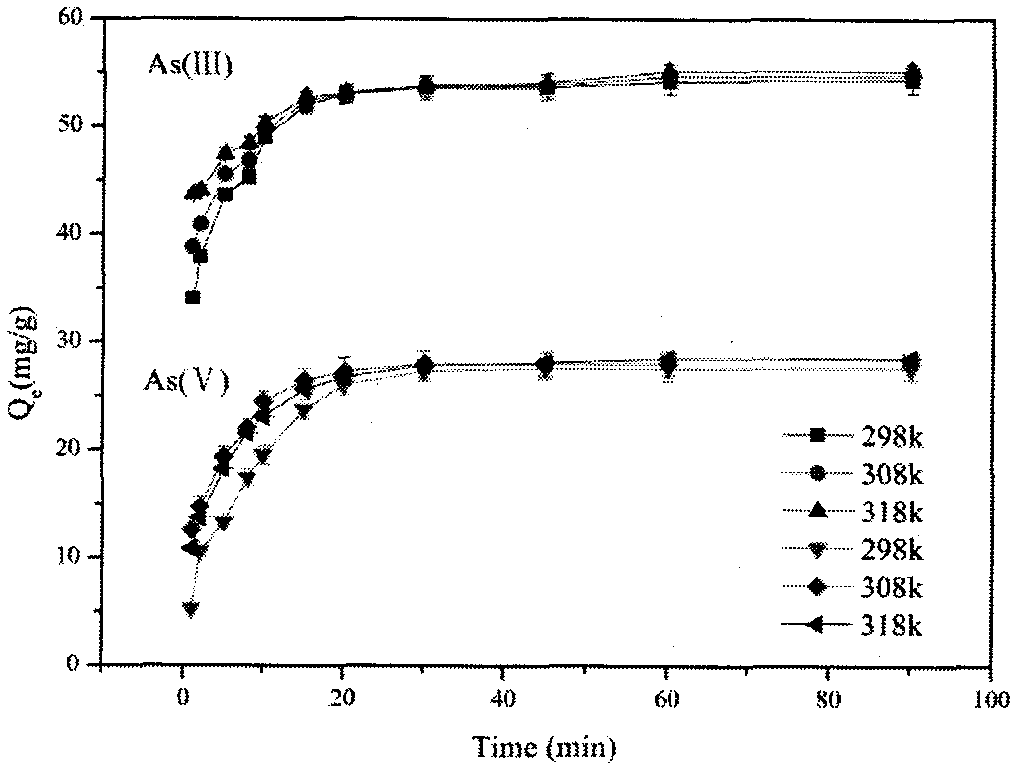

[0037] The adsorption amount of As(III) and As(V) in the solution by the ionic liquid modified magnetic graphene oxide composite material under different adsorption time conditions was compared, and the specific steps were as follows:

[0038] Add 20 mg of the material obtained in Example 1 to 50 mL of pH=7 solution containing 50 mg / L As(III) and As(V), shake at 25°C (200 rpm), and the adsorption time is: 1, 2, 5 , 8, 10, 15, 20, 30, 45, 60, 90min. The results showed that after 30 min, the adsorption reached equilibrium, and the adsorption process obeyed the second-order kinetics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com