Low temperature resistant modified asphalt waterproof roll material

A technology of modified asphalt and waterproofing membrane, applied in building thermal insulation materials, building components, fiber types, etc., can solve the problems of poor low temperature resistance, low temperature embrittlement, and anti-aging properties to be further improved, and achieve low temperature resistance. Remarkable performance, good tear resistance, and the effect of improving embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

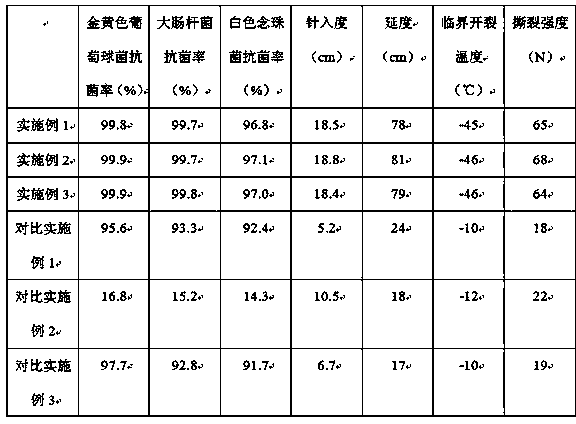

Examples

Embodiment 1

[0019] A modified asphalt waterproof membrane resistant to low temperature, characterized in that it includes modified asphalt, modified polyester tire, and PE film, and is characterized in that the modified asphalt is made of the following raw materials in parts by weight: Longyan kaolin 4 , metakaolin 5, polyacrylamide 2, tea tree oil 10, hydroxymethyl cellulose 20, asphalt 80, SBS rubber 10, aromatic oil 10, rosin resin 5.

[0020] Further, the preparation method of described modified asphalt comprises the following steps:

[0021] (1) Put Longyan kaolin and metakaolin in a freeze-drying box, freeze-dry at -30°C for 5 hours, then put them in a microwave device, microwave for 20s, take them out, crush them to particles with a diameter of less than 5mm, and put them in Add polyacrylamide, tea tree oil, carboxymethyl cellulose and clear water into the ball mill, ball mill at 60°C for 4 hours, and pass through a 200-mesh sieve to obtain a uniform slurry, then heat the slurry to...

Embodiment 2

[0030] A modified asphalt waterproof membrane resistant to low temperature, characterized in that it includes modified asphalt, modified polyester tire, and PE film, and is characterized in that the modified asphalt is made of the following raw materials in parts by weight: Longyan kaolin 5 , metakaolin 7, polyacrylamide 3, tea tree oil 15, hydroxymethyl cellulose 22, asphalt 90, SBS rubber 15, aromatic oil 15, rosin resin 7.

[0031] Further, the preparation method of described modified asphalt comprises the following steps:

[0032] (1) Put Longyan kaolin and metakaolin in a freeze-drying box, freeze-dry at -32°C for 8 hours, then put them into a microwave device, microwave for 25s, take them out, crush them to particles with a diameter of less than 5mm, and put them in Add polyacrylamide, tea tree oil, carboxymethyl cellulose and clear water into the ball mill, ball mill at 65°C for 5 hours, and pass through a 250-mesh sieve to obtain a uniform slurry, then heat the slurry ...

Embodiment 3

[0041] A modified asphalt waterproof membrane resistant to low temperature, characterized in that it includes modified asphalt, modified polyester tire, and PE film, and is characterized in that the modified asphalt is made of the following raw materials in parts by weight: Longyan kaolin 6 , Metakaolin 10, polyacrylamide 3, tea tree oil 20, hydroxymethyl cellulose 25, asphalt 100, SBS rubber 20, aromatic oil 20, rosin resin 10.

[0042] Further, the preparation method of described modified asphalt comprises the following steps:

[0043](1) Put Longyan kaolin and metakaolin in a freeze-drying box, freeze-dry at -35°C for 10 hours, then put them in a microwave device, microwave for 30s, take them out and crush them into particles with a diameter of less than 5mm, and put them in Add polyacrylamide, tea tree oil, carboxymethyl cellulose and clear water into the ball mill, ball mill at 70°C for 5 hours, and pass through a 300-mesh sieve to obtain a uniform slurry, then heat the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com