Method for preparing different tones of indigo pigments based on blueberry leaves

A technology of black rice leaves and indigo pigment, which is applied in the field of natural plant pigment preparation, can solve the problems of limited color selection, poor water solubility of blue pigment, and imperfect preparation method, etc., and achieves good stability and nutrition, Good purification effect and good impurity removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

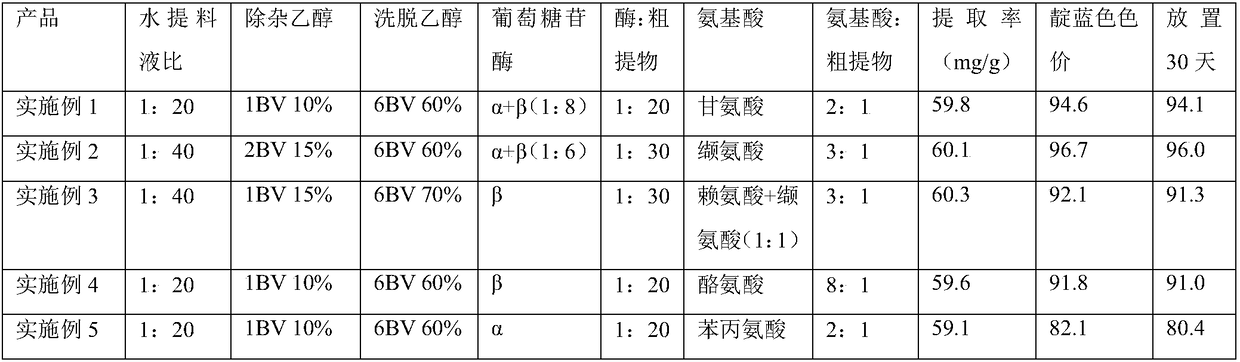

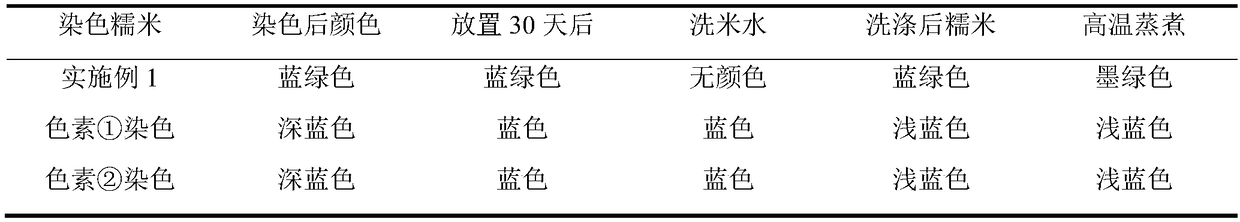

Examples

Embodiment 1

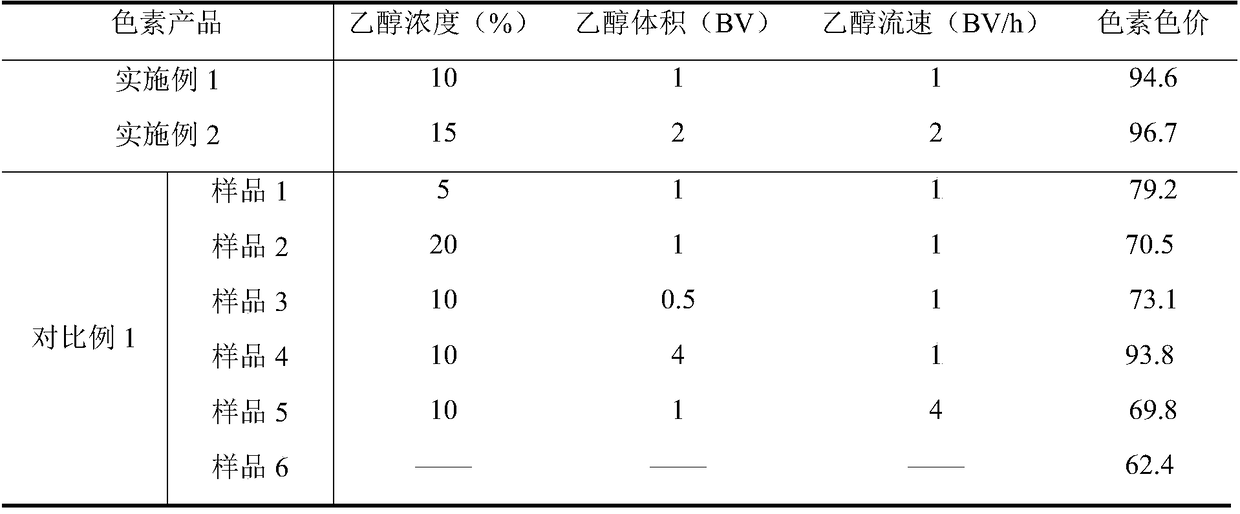

[0042] Freeze-dry the leaves of Wufan tree, pass through a 60-mesh sieve after being crushed. Accurately weigh 10g of black rice leaf powder and add 200g of distilled water, carry out heat preservation water extraction (i.e. the ratio of solid to liquid is 1:20) under the condition of 30°C water bath, the extraction time is 2h, and the extraction times are 3 times to obtain the water extract.

[0043] The above-mentioned water extract was refrigerated and centrifuged for 10min (6000r / min) to obtain the supernatant, and the supernatant was filtered by an ultrafiltration membrane with a pore size of 30nm to obtain the crude extract of the leaves of the black rice. Pass the crude extract through AB-8 macroporous adsorption resin at a flow rate of 2BV / h, remove impurities with distilled water until the eluate is colorless, and then use 1BV of 10% ethanol to remove the adsorbed on the column at a flow rate of 1BV / h The non-pigment components were finally eluted with 6BV 60% ethanol...

Embodiment 2

[0053] Freeze-dry the leaves of Wufan tree, pass through an 80-mesh sieve after being crushed. Accurately weigh 10g of black rice leaf powder and add 400g of distilled water, and carry out heat preservation water extraction (i.e., the ratio of solid to liquid is 1:40) under the condition of 30°C water bath. The extraction time is 3h, and the extraction times are 4 times to obtain the water extract.

[0054] The above-mentioned water extract was refrigerated and centrifuged for 15min (6000r / min) to obtain the supernatant, and the supernatant was filtered through an ultrafiltration membrane with a pore size of 30nm to obtain the crude extract of the leaves of the black rice leaf. Pass the crude extract through AB-8 macroporous adsorption resin at a flow rate of 2BV / h, first remove impurities with distilled water until the eluate is colorless, and then use 2BV 15% ethanol to remove the adsorbed on the column at a flow rate of 2BV / h The non-pigment components were finally eluted w...

Embodiment 3

[0064] The operating conditions of embodiment 3 are shown in Table 1, and all the other operations and conditions are consistent with embodiment 2.

[0065] Concentrate the indigo aqueous solution obtained by evaporation under reduced pressure and then freeze-dry to obtain the finished indigo pigment. The color value is 92.1. The blue tone corresponds to the color number of the Pantone color card, and the color number close to it is PANTONG 2965C. The results are shown in Table 1 .

[0066] The above-mentioned indigo blue aqueous solution is heated to boiling, and its color has no obvious change.

[0067] Dissolving the above-mentioned finished indigo pigment in acidic solution with pH=3-4 or alkaline solution with pH=8-9, the color has no obvious change and can exist stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com