A functional separator for lithium-sulfur batteries, its preparation method and application in lithium-sulfur batteries

A lithium-sulfur battery and a functional technology, applied in the field of electrochemistry, can solve the problems of difficult to prepare composite cathode materials with high sulfur loading, complicated preparation process of porous carbon structure, discount of application value of lithium-sulfur batteries, etc. Reaction, inhibition of shuttle effect, effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

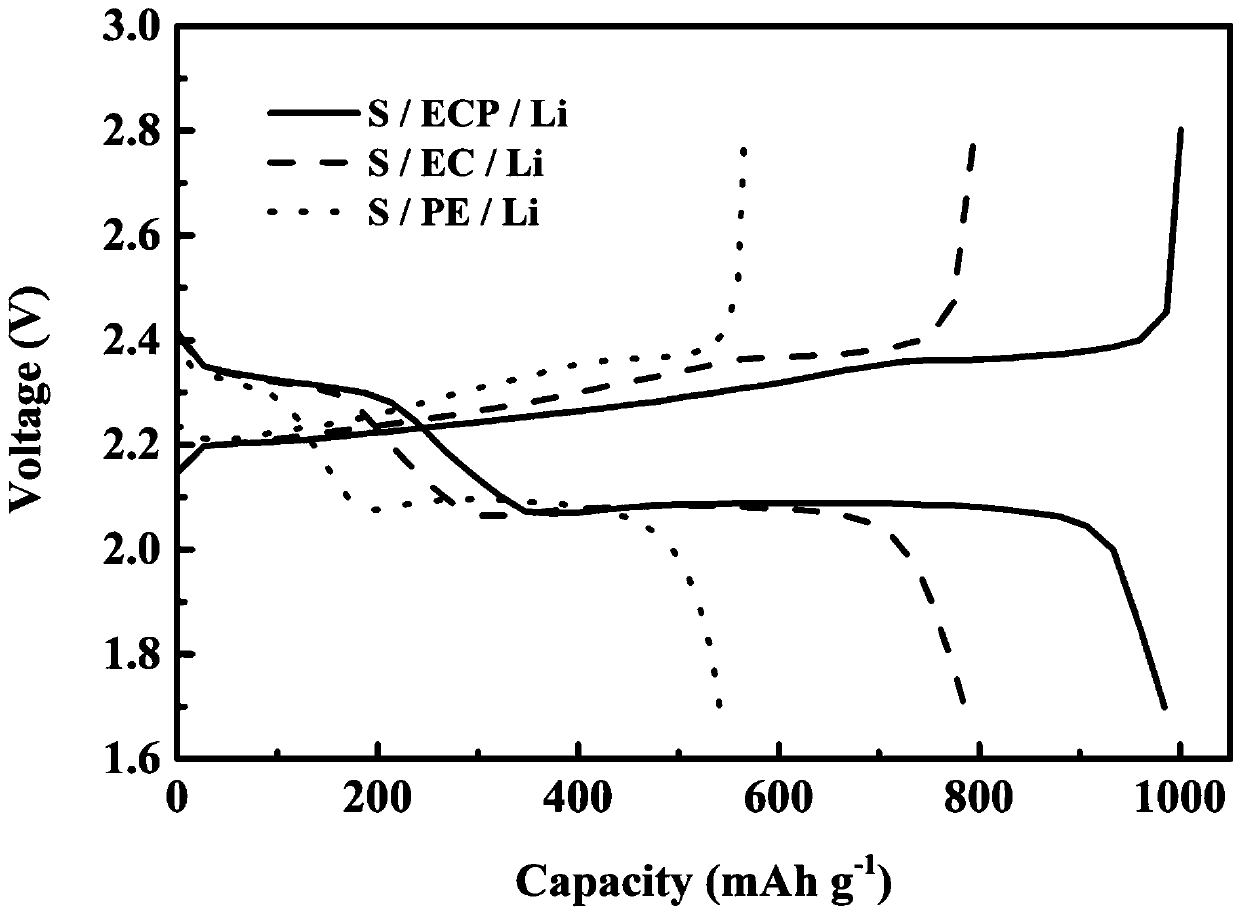

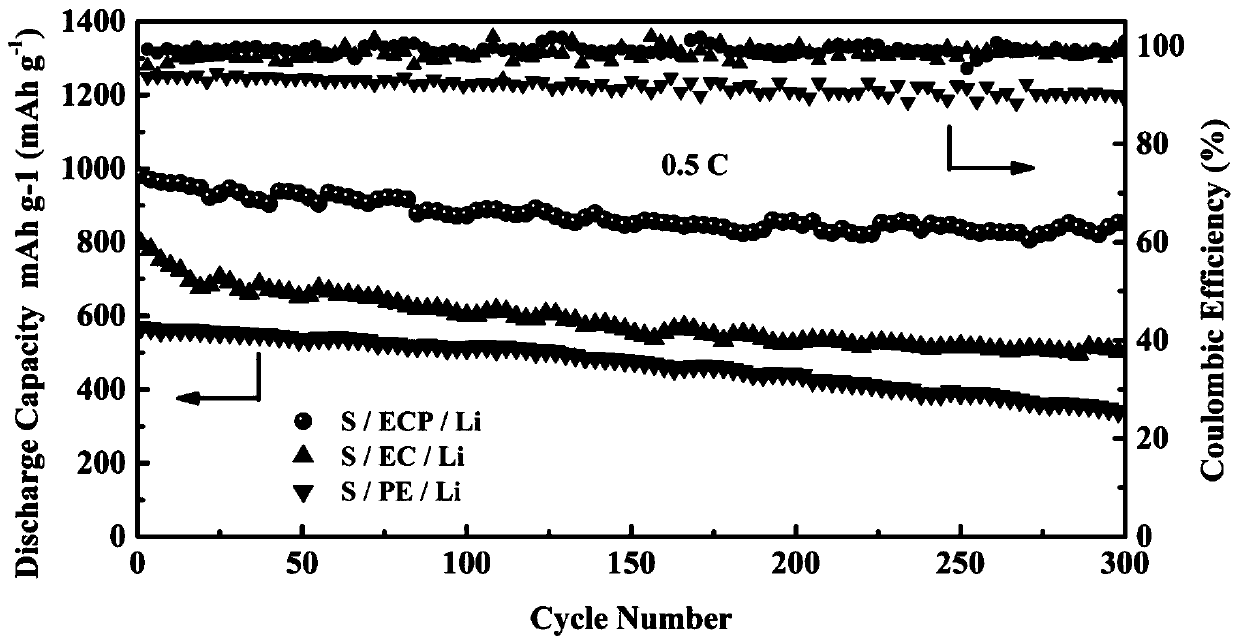

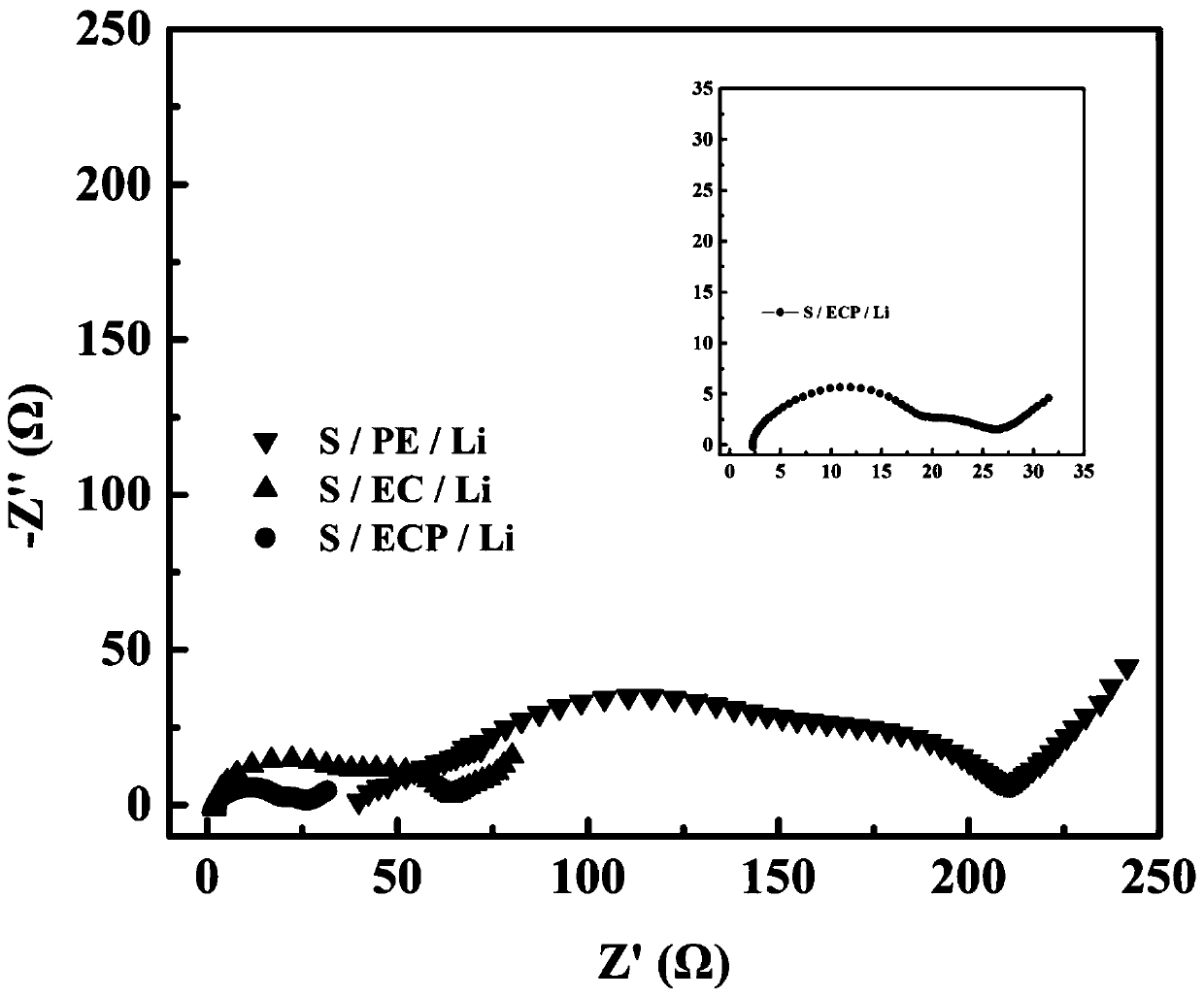

[0045] Fabrication of lithium-sulfur batteries with functional separators:

[0046] (1) Weigh 4.0 g of sublimated sulfur and 1.0 g of conductive carbon black Super P and place them in a mortar. After the sublimated sulfur and conductive carbon materials are fully ground and mixed, the obtained sulfur / carbon mixture is first dried in an oven for 4 h, and then Transfer the mixture to a hydrothermal reaction kettle filled with inert gas in the glove box, and heat-treat it in a vacuum drying oven at 100-200°C for 2-12 hours to obtain a sulfur / carbon composite material, and the obtained product is named S / C.

[0047] (2) Mix the above-prepared S / C composite material with conductive carbon black Super P and binder PVDF in a mortar with a mass ratio of 7:2:1, and N-methylpyrrolidone (NMP) solution as a dispersant , fully grind to make the mixture uniform, and then apply the coating slurry on the surface of the pre-cut aluminum foil by the doctor blade coating method to make a sulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com