Desulfurization and denitrification system and technology thereof

A technology for desulfurization and denitrification, flue gas, applied in the field of desulfurization and denitrification system and its technology, can solve the problems of high cost, incomplete removal, low desulfurization and denitrification efficiency, etc., and achieve low cost, high desulfurization and denitrification efficiency, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

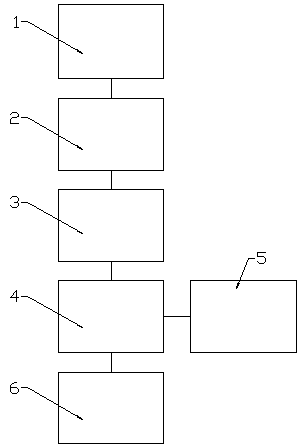

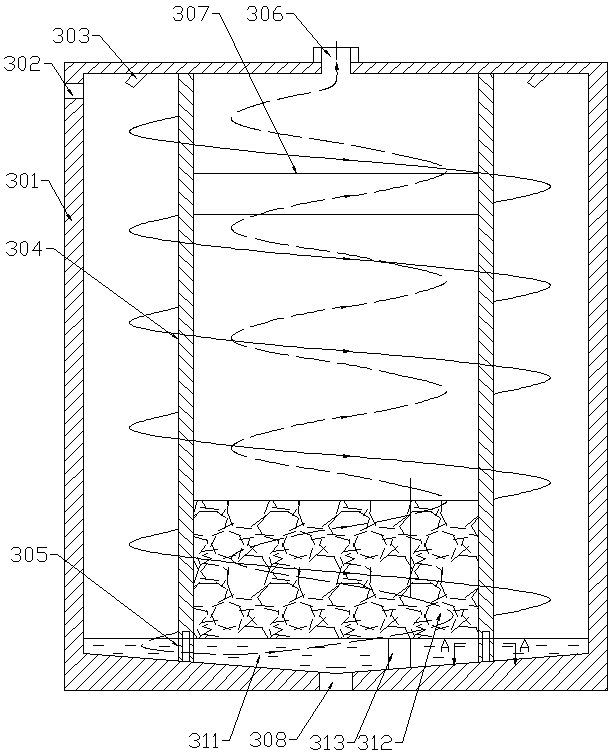

[0041] Such as Figures 1 to 3 As shown, a desulfurization and denitrification system of the present invention includes a flue gas pretreatment device 1, an induced draft fan 2, a spray tower 3 and a circulation pool 4 connected in sequence, and the spray tower 3 includes a cylindrical shell 301, The upper end of the casing 301 is provided with an air inlet 302 connected to the induced draft fan 2 and a nozzle 303 connected to the circulation pool 4, the casing 301 is provided with an inner cylinder 304, and the bottom of the inner cylinder 304 is provided with an opening 305 to communicate the inner and outer spaces of the inner cylinder 304, The height of the opening 305 is higher than the liquid level of the absorption liquid 311 at the bottom of the shell 301, and the top of the inner cylinder 304 is provided with an air outlet 306 to discharge the purified flue gas, and the air inlet 302 is arranged along the tangential direction so that the flue gas spirals along the side...

specific Embodiment 2

[0045] Such as figure 1 , 4 , 5, a desulfurization and denitrification system of the present invention includes a flue gas pretreatment device 1, an induced draft fan 2, a spray tower 3 and a circulation pool 4 connected in sequence, and the spray tower 3 includes a cylindrical shell 301, the upper end of the casing 301 is provided with an air inlet 302 connected to the induced draft fan 2 and a nozzle 303 connected to the circulation pool 4, the casing 301 is provided with an inner cylinder 304, and the bottom of the inner cylinder 304 is provided with an opening 305 to make the internal and external space of the inner cylinder 304 The height of the opening 305 is higher than the liquid level of the absorption liquid 311 at the bottom of the shell 301, the top of the inner cylinder 304 is provided with an air outlet 306 to discharge the purified smoke, and the air inlet 302 is set along the tangential direction so that the smoke flows along the side of the shell 301. wall sp...

specific Embodiment 3

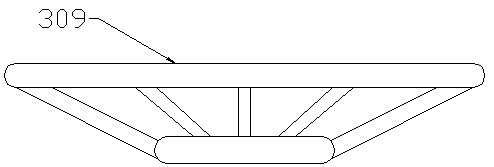

[0049] Such as Image 6 with Figure 7 As shown, another embodiment of the communication pipe 309, the communication pipe 309 is a double circular ring connected, the outer ring of the communication pipe 309 is between the outer shell 301 and the inner cylinder 304 and is higher than the absorption liquid level at the bottom of the outer cylinder 301 For the entry of flue gas, the inner ring of the connecting pipe 309 is in the inner cylinder 304 and is lower than the liquid level of the absorption liquid 311 at the bottom of the inner cylinder 304. The inner ring is evenly distributed with multiple exhaust ports 310 along the circumferential direction, and the exhaust ports 310 are inclined It is set so that the flue gas spirals up in the absorption liquid 311 .

[0050] The rest of the features are the same as those in Embodiment 2 and will not be described in detail.

[0051] Such as Figure 8 As shown, the desulfurization and denitrification method of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com