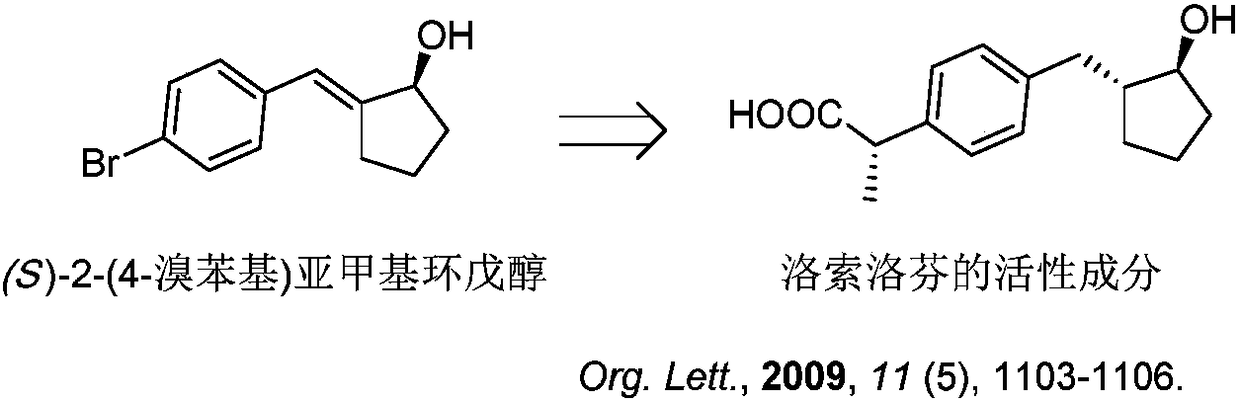

Chiral 2-aromatic methylene naphthenic alcohol and asymmetric synthesizing method thereof

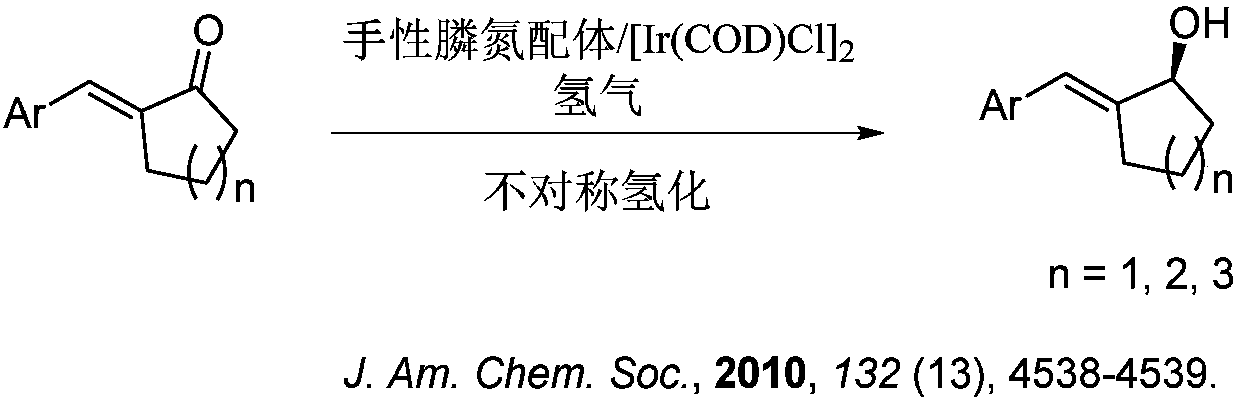

A technology for arylmethylenecycloalkanol and its synthesis method, which is applied in the field of chiral 2-arylmethylenecycloalkanol and its asymmetric synthesis, can solve the problems of high price of chiral ligands, and achieve mild reaction conditions , simple synthesis and convenient experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

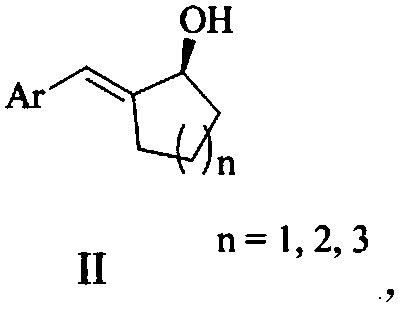

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the synthesis of (E)-2-phenylmethylene cyclohexanol

[0028]

[0029] Add 0.2mmol (E)-2-phenylmethylenecyclohexanone to a 10ml sealed test tube, add 1 mmol formic acid / triethylamine, add 0.004mmol catalyst, 1mL solvent, seal the test tube, and react at 30°C for 6 Hour. After the reaction was finished, the reaction was washed with water, the aqueous phase was extracted 3 times with ethyl acetate, the combined organic phase was concentrated to dryness, and the product was separated by column chromatography (petroleum ether: ethyl acetate=10:1), and the enantiomeric excess (ee ) value. HPLC separation conditions: chiral column OD-H column, mobile phase: n-hexane / isopropanol=90:10 (volume ratio), flow rate: 1.0 ml / min, wavelength: 254 nm, column temperature: 30 degrees Celsius, t 1 = 6.41 minutes, t 2 = 7.79 minutes; 1 H NMR (400MHz, CDCl 3 ):δ=7.37(t,J=7.6Hz,2H,Ar–H), 7.26(t,J=6.8Hz,3H,Ar–H),6.57(s,1H,C=CH),4.31–4.27 (m,1H,OCH), 2.80-2.73(m,1H,CH 2 ...

Embodiment 2

[0032] Embodiment 2: the synthesis of (E)-2-(3-methoxybenzylidene) cyclohexanol

[0033]

[0034] Add 0.2mmol (E)-2-(3-methoxybenzylidene)cyclohexanone to a 10ml sealed test tube, add 1mmol formic acid / triethylamine (1.1:1), add 0.004mmol catalyst E, Chloroform 1mL, seal the test tube, and react at 30°C for 6 hours. After the reaction was finished, it was washed with water, the aqueous phase was extracted 3 times with ethyl acetate, the combined organic phases were concentrated to dryness, and the isolated yield was 86% (petroleum ether: ethyl acetate=10:1), and the enantiomeric excess of 82% was determined by HPLC. ee value. HPLC separation conditions: chiral column OD-H column, mobile phase: n-hexane / isopropanol=90:10 (volume ratio), flow rate: 1.0 ml / min, wavelength: 254 nm, column temperature: 30 degrees Celsius, t 1 = 10.12 minutes, t 2 = 14.05 minutes; 1 H NMR (400MHz, CDCl 3 ):δ=7.27(d,J=8.4Hz,1H,Ar–H),6.87-6.81(m,3H,Ar–H),6.54(s,1H,C=CH),4.29–4.26(m, 1H,OCH),3...

Embodiment 3

[0035] Embodiment 3: the synthesis of (E)-2-(2-methylbenzylidene) cyclohexanol

[0036]

[0037] Add 0.2 mmol (E)-2-(2-methylbenzylidene) cyclohexanone to a 10 ml sealed test tube, add 1 mmol formic acid / triethylamine (1.1:1), add 0.004 mmol catalyst E, Chloroform 1mL, seal the test tube, and react at 30°C for 6 hours. After the reaction was finished, it was washed with water, the aqueous phase was extracted 3 times with ethyl acetate, the combined organic phases were concentrated to dryness, the separation yield was 80% (petroleum ether: ethyl acetate=10:1), and the enantiomeric excess of 83% was determined by HPLC. ee value. HPLC separation conditions: chiral column OD-H column, mobile phase: n-hexane / isopropanol=90:10 (volume ratio), flow rate: 1.0 ml / min, wavelength: 254 nm, column temperature: 30 degrees Celsius, t 1 = 5.87 minutes, t 2 = 6.86 minutes; 1 H NMR (400MHz, CDCl3 ):δ=7.24-7.17(m,3H,Ar–H),7.15-7.12(m,1H,Ar–H),6.51(s,1H,C=CH),4.33–4.30(m,1H,OCH ),2.59-2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com