Absorbing material and preparation method thereof

A technology of absorbing materials and matrix materials, applied in the field of materials, can solve the problems of sacrificing the absorbing properties of materials, high patch density, poor designability, etc., achieving good designability, ensuring wave absorption performance, and strong designability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

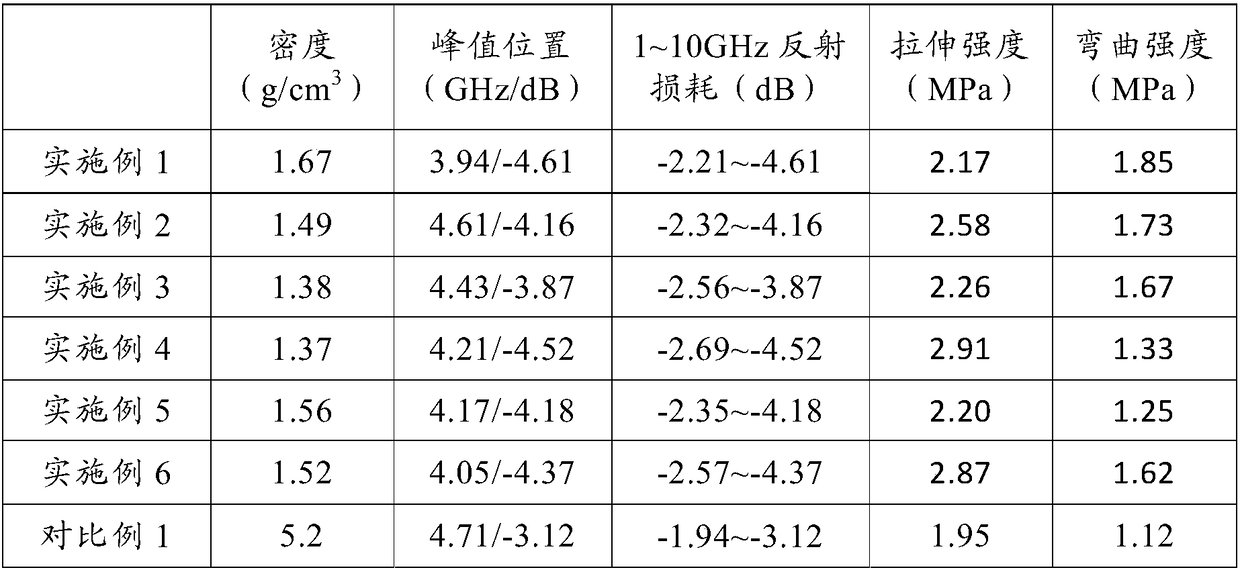

Examples

Embodiment 1

[0026] Add the hollow glass microspheres to the sodium hydroxide solution to prepare a hollow glass microsphere solution with a mass fraction of 5%, stir at 70°C for 40 minutes, filter, and then add SnCl 2 -HCl solution, 50 ° C ultrasonic vibration for 60 minutes, filtered, and then added to PdCl 2 -HCl solution, 50 ℃ ultrasonic vibration for 60min activation, after that, in the electrolyte composed of nickel salt, iron salt, conductive salt, pH buffer solution, with nickel and iron as the anode, on the surface of the activated hollow glass microspheres Plating a uniform nickel layer and iron layer to obtain the magnetic hollow microspheres;

[0027] In parts by mass, 100 parts of two-component polyurethane composed of polyisocyanate and hydroxyl resin are dissolved in 30 parts of ethyl acetate solvent to form the ethyl acetate solution of two-component polyurethane; Add 260 parts of magnetic hollow microspheres in batches to the solution, then add 5 parts of anti-aging agent...

Embodiment 2

[0029] Add hollow glass microspheres to potassium hydroxide solution to prepare a hollow glass microsphere solution with a mass fraction of 10%, stir at 80°C for 20 min, filter, and then add SnCl 2 -HCl solution, 30 ℃ ultrasonic vibration for 80min, filtered, then added to PdCl 2 -HCl solution, 30 ℃ ultrasonic vibration for 80min activation, after that, in the electrolyte composed of nickel salt, iron salt, conductive salt, pH buffer solution, with nickel and iron as the anode, on the surface of the activated hollow glass microspheres Plating a uniform nickel layer and iron layer to obtain the magnetic hollow microspheres;

[0030]In parts by mass, 80 parts of two-component polyurethane composed of polyisocyanate and hydroxyl resin are dissolved in 25 parts of ethyl acetate solvent to form the ethyl acetate solution of two-component polyurethane; Add 220 parts of magnetic hollow microspheres in batches to the solution, then add 3 parts of anti-aging agent RD, use a high-speed...

Embodiment 3

[0032] Add hollow glass microspheres to sodium hydroxide solution to prepare a hollow glass microsphere solution with a mass fraction of 10%, stir at 60°C for 40 min, filter, and then add SnCl 2 -HCl solution, 70 ° C ultrasonic vibration for 40 minutes, filtered, and then added to PdCl 2 -HCl solution, 70 ℃ ultrasonic vibration for 40min activation, after that, in the electrolyte composed of nickel salt, iron salt, conductive salt, pH buffer solution, with nickel and iron as the anode, on the surface of the activated hollow glass microspheres Plating a uniform nickel layer and iron layer to obtain the magnetic hollow microspheres;

[0033] In parts by mass, 100 parts of two-component polyurethane composed of polyisocyanate and hydroxyl resin are dissolved in 20 parts of ethyl acetate solvent to form the ethyl acetate solution of two-component polyurethane; Add 200 parts of magnetic hollow microspheres in batches to the solution, and then add 5 parts of anti-aging agent N-isop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com