High-strength flame-retardant air filtering material and preparation method thereof

An air filter material and filter material technology, which is applied in the field of high-strength flame-retardant air filter material and its preparation, can solve the problems of poor filter effect and short service life, etc., so as to prolong service life, improve durability and good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

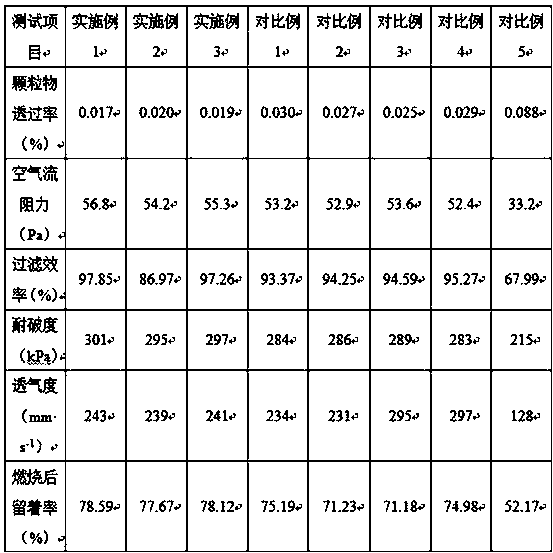

Examples

preparation example Construction

[0028] The preparation method of filter material base material is:

[0029] (1) Take lithium chloride and add N,N-dimethylformamide according to the mass ratio of 1~4:8~10, keep the humidity at 40~50%, stir and mix at 25~30°C for 20~30min, and then Add polyacrylonitrile with 4 to 6 times the mass of lithium chloride, and magnetically stir for 10 to 12 hours to obtain a stirred mixture;

[0030] (2) Take carbon nanotubes and add N,N-dimethylformamide according to the mass ratio of 1~4: 8~10, and stir for 20~30min to obtain the mixture. Take nitric acid with a concentration of 3mol / L according to the mass ratio of 3~5: 1~3 Add sulfuric acid with a concentration of 1mol / L, stir and mix for 15~20min to obtain a mixed solution, take the mixture according to the mass ratio of 3~6:30~40, add the mixed solution, raise the temperature to 100~110°C, stir and mix for 18~24h, Suction filtration, take the suction filter residue, wash with deionized water, rotary evaporate, and dry to obta...

Embodiment 1

[0042] The preparation method of filter material base material is:

[0043] (1) Take lithium chloride and add N,N-dimethylformamide at a mass ratio of 1:8, keep the humidity at 40%, stir and mix at 25°C for 20 minutes, then add polypropylene with 4 times the mass of lithium chloride Nitrile, magnetically stirred for 10h to obtain a stirred mixture;

[0044] (2) Take carbon nanotubes and add N,N-dimethylformamide at a mass ratio of 1:8, and stir for 20 minutes to obtain a mixture. Take nitric acid with a concentration of 3 mol / L and add nitric acid with a concentration of 1 mol / L at a mass ratio of 3:1 Sulfuric acid, stirred and mixed for 15 minutes to obtain a mixed solution, took the mixture and added it to the mixed solution according to the mass ratio of 3:30, raised the temperature to 100°C and stirred and mixed for 18 hours, then suction filtered, took the suction filter residue, washed it with deionized water, rotary evaporated, and dried to obtain a dry product ;

[0...

Embodiment 2

[0056] The preparation method of filter material base material is:

[0057] (1) Take lithium chloride and add N,N-dimethylformamide in a mass ratio of 3:9, keep the humidity at 45%, stir and mix at 28°C for 25 minutes, then add polypropylene with 5 times the mass of lithium chloride Nitrile, magnetically stirred for 11h to obtain a stirred mixture;

[0058] (2) Take carbon nanotubes and add N,N-dimethylformamide at a mass ratio of 3:9, and stir for 25 minutes to obtain a mixture. Take nitric acid with a concentration of 3 mol / L and add nitric acid with a concentration of 1 mol / L at a mass ratio of 4:2. Sulfuric acid, stirred and mixed for 18 minutes to obtain a mixed solution, took the mixture and added it to the mixed solution at a mass ratio of 5:35, raised the temperature to 105°C, stirred and mixed for 20 hours, filtered with suction, took the suction filter residue, washed it with deionized water, rotated evaporated, and dried to obtain a dry product ;

[0059] (3) Take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com