A kind of using ionic liquid to carry out CO in flue gas 2 Capture device and process

An ionic liquid and process technology, applied in the field of high-purity CO2 product gas devices, can solve problems such as difficult flow, low regeneration efficiency, and increased energy consumption, and achieve small heat capacity and evaporation enthalpy, reduced regeneration energy consumption, and improved regeneration energy The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

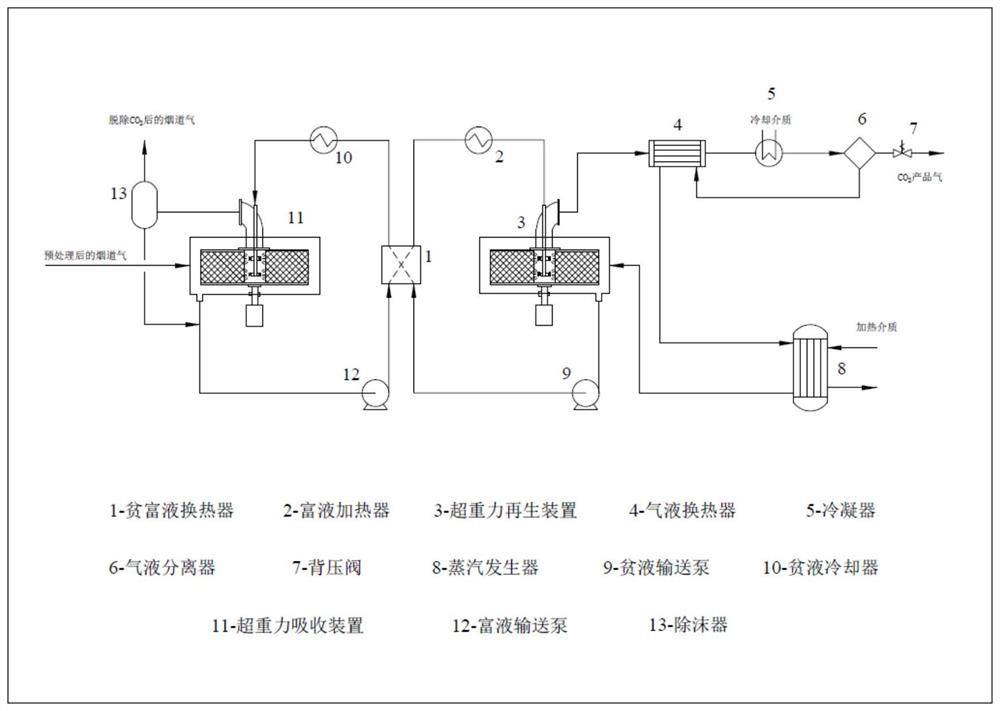

[0031] CO in flue gas using the above-mentioned device 2 capture. Wherein, the ionic liquid absorbent used is [1-(3-propylamino)-3-butylimidazole bistrifluoromethanesulfonimine salt] ([Apbim][Tf 2 N]), the temperature in the supergravity absorption device is controlled at 30-40°C, the pressure is 0.1-0.2MPa, the supergravity level is 150, and the gas-liquid volume flow ratio is 150:1-200:1; the ionic liquid rich liquid is in The rich liquid heater is heated to 110°C; the temperature in the supergravity regeneration device is 110°C, the pressure is 0.1-0.2MPa, the supergravity level is 200, and the volume flow ratio of stripping steam and ionic liquid rich liquid is 70:1~ 100:1, the stripping steam used is n-pentane steam; the outlet temperature of the condenser is 0-10°C; the temperature inside the steam generator is 75°C; the lean liquid cooler cools the regenerated ionic liquid to 30-40°C .

[0032] Sampling and analysis at the gas outlet of the supergravity absorption de...

Embodiment 2

[0034] As described in Example 1, other conditions remained unchanged, and the temperature of the supergravity absorption device was adjusted to 50°C. Sampling and analysis at the gas outlet of the supergravity absorption device, CO 2 The concentration is 1.8%, sampling and analysis at the gas-liquid separator outlet, CO 2 Gas purity can reach 99%.

Embodiment 3

[0036] As described in Example 1, other conditions remain unchanged, and the supergravity level of the supergravity absorbing device is adjusted to 200. Sampling and analysis at the gas outlet of the supergravity absorption device, CO 2 The concentration is 1.2%, sampling and analysis at the gas-liquid separator outlet, CO 2 Gas purity can reach 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com