Nano graphene as well as preparation method and application thereof, and method for preparing solar heat collection pipe

A solar collector tube, nano-graphene technology, applied in the directions of graphene, nano-carbon, chemical instruments and methods, etc., to achieve the effect of improving light absorption and improving heat collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of nano-graphene of the present invention comprises the following steps:

[0039] (1) Measure 82.8 mL of sulfuric acid, 9.2 mL of phosphoric acid, 40 mL of hydrogen peroxide, 4 g of graphite powder and 12 g of potassium permanganate;

[0040] (2) Put the dried 250mL beaker in an ice-water bath and put it into a magnetic stirrer, add the weighed sulfuric acid and phosphoric acid into the beaker by means of glass rod drainage, control the temperature of the system at 1 °C, and let It is stirred and mixed evenly;

[0041] (3) slowly add 4g graphite powder to the beaker and continue stirring for 1h;

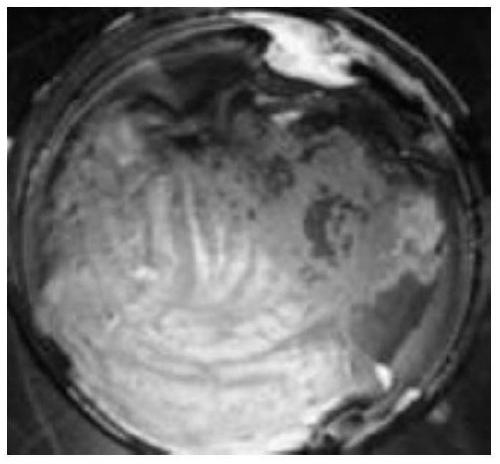

[0042] (4) Controlling the temperature at 2°C, slowly adding potassium permanganate in portions to the beaker for 2h, and stirring continuously for 2h; then transfer the system to a 35°C water bath, and continue stirring for 30min;

[0043] (5) Slowly drop deionized water into the beaker, slowly raise the temperature of the system to 85°C, and continue...

Embodiment 2

[0052] The preparation method of nano-graphene of the present invention comprises the following steps:

[0053](1) Measure 31.5 mL of sulfuric acid, 3.5 mL of phosphoric acid, 10 mL of hydrogen peroxide, 1.5 g of graphite powder and 4.5 g of potassium permanganate;

[0054] (2) place the dried beaker in an ice-water bath, now add sulfuric acid to the beaker by means of glass rod drainage, then add phosphoric acid to the beaker by means of glass rod drainage, and control the temperature of the system at 2°C;

[0055] (3) continue to add 1.5g graphite powder to the beaker, continue to stir, and react for 1h;

[0056] (4) Slowly add 4.5g potassium permanganate to the beaker in stages, add potassium permanganate for 1 hour, maintain the temperature of the system at 5 °C, and react for 2 hours, then transfer the system to a water bath at 38 °C and continue to stir Reaction 30min; wherein, when potassium permanganate is added, it must be slow to prevent sulfuric acid from splashing...

Embodiment 3

[0066] The preparation method of nano-graphene of the present invention comprises the following steps:

[0067] (1) Measure 54.9 mL of sulfuric acid, 6.1 mL of phosphoric acid, 20 mL of hydrogen peroxide, 2.8 g of graphite powder and 8.4 g of potassium permanganate;

[0068] (2) place the dried beaker in an ice-water bath, now add sulfuric acid to the beaker by means of glass rod drainage, then add phosphoric acid to the beaker by means of glass rod drainage, and control the temperature of the system at 4°C;

[0069] (3) continue to add 2.8g graphite powder to the beaker, continue to stir, and react for 2h;

[0070] (4) Slowly add 8.4g of potassium permanganate to the beaker, the time for adding potassium permanganate is 2h, maintain the temperature of the system at 7°C, stir while adding, and then transfer the system to a water bath at 40°C Continue to stir the reaction for 1h; among them, the potassium permanganate must be added slowly to prevent the sulfuric acid from spla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com