High-energy-storage barium titanate dielectric material and preparation method thereof

A dielectric material and barium titanate technology are applied in the field of high energy storage barium titanate-based dielectric materials and their preparation, which can solve the problems of low discharge energy storage density and the like, and achieve the effect of good capacitance temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

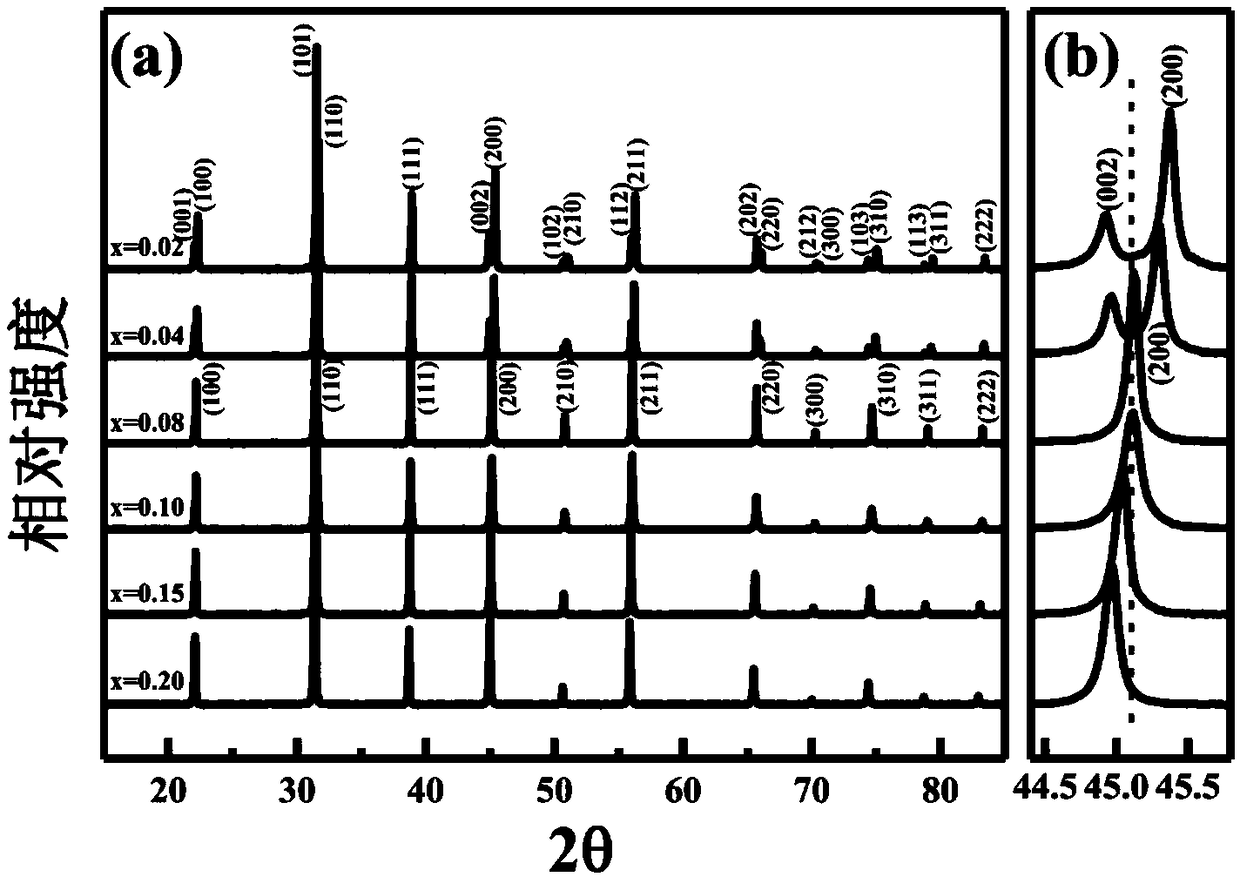

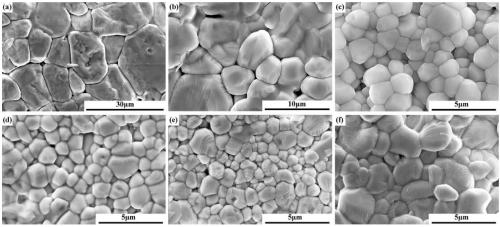

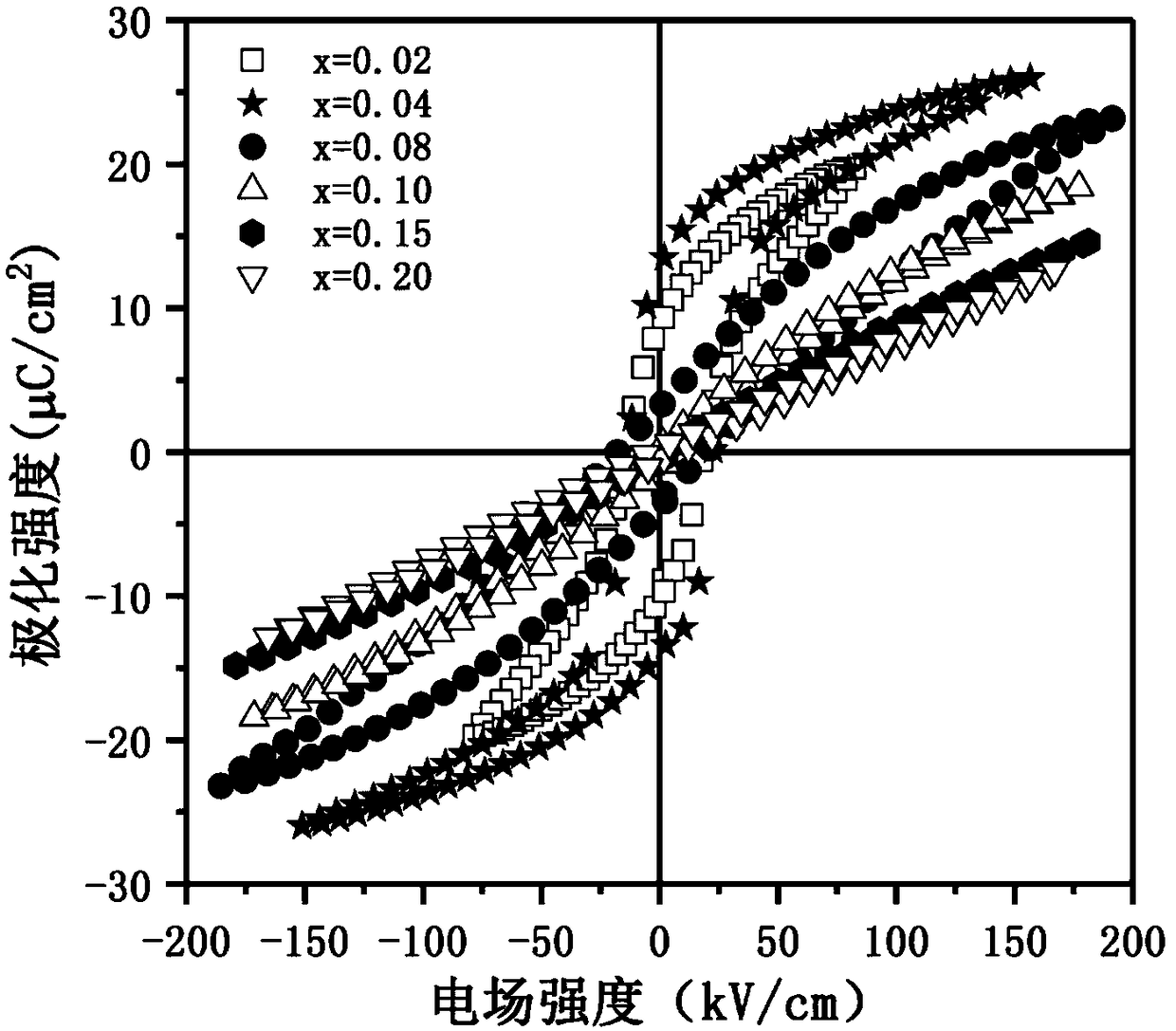

[0031] A high-energy storage barium titanate-based dielectric material whose chemical composition is expressed as 0.98BaTiO 3 -0.02Bi(Mg 1 / 2 Zr 1 / 2 )O 3 , its preparation method specifically comprises the following steps:

[0032] (1) Weigh 0.98mol BaCO according to the composition expression 3 , 0.98mol TiO 2 , 0.01mol Bi 2 o 3 , 0.01molMgO and 0.01mol ZrO 2 as a raw material;

[0033] (2) Put the raw materials into a ball mill jar, use zirconia balls and absolute ethanol as the medium, and mill them on a planetary ball mill for 8 hours; then dry them at 100°C for 24 hours and pre-fire them. Raise the temperature to 1000°C at a heating rate of 3°C / min, keep it warm for 4 hours, and cool naturally with the furnace; planetary ball mill the pre-fired powder for 4 hours, and then dry it at 100°C for 24 hours to obtain ceramic powder;

[0034](3) Add a polyvinyl alcohol aqueous solution with a concentration of 5wt.% to the ceramic powder, the addition of the polyvinyl a...

Embodiment 2

[0041] A high-energy storage barium titanate-based dielectric material, the chemical composition expression of which is 0.96BaTiO 3 -0.04Bi(Mg 1 / 2 Zr 1 / 2 )O 3 , its preparation method comprises the following steps:

[0042] (1) Weigh 0.96mol BaCO according to the chemical formula 3 , 0.96mol TiO 2 , 0.02mol Bi 2 o 3 , 0.02mol MgO and 0.02mol ZrO 2 as a raw material;

[0043] (2) Put the raw materials into a ball mill jar, use zirconia balls and absolute ethanol as the medium, and mill them on a planetary ball mill for 8 hours; then dry them at 100°C for 24 hours and pre-fire them. The heating rate of ℃ / min was raised to 970 ℃, kept for 4 hours, and cooled naturally with the furnace; the pre-fired powder was planetary ball milled for 4 hours, and then dried at 100 ℃ for 24 hours to obtain ceramic powder;

[0044] (3) Add polyvinyl alcohol aqueous solution to the ceramic powder, its concentration is 5wt.%, the addition is 3% of ceramic powder mass, mix and granulate, ...

Embodiment 3

[0051] A high-energy storage barium titanate-based dielectric material, the chemical composition expression of which is 0.92BaTiO 3 -0.08Bi(Mg 1 / 2 Zr 1 / 2 )O 3 , its preparation method comprises the following steps:

[0052] (1) Weigh 0.92mol BaCO according to the chemical formula 3 , 0.92mol TiO 2 , 0.02mol Bi 2 o 3 , 0.02mol MgO and 0.02mol ZrO 2 as a raw material;

[0053] (2) Put the raw materials into a ball mill jar, use zirconia balls and absolute ethanol as the medium, and mill them on a planetary ball mill for 8 hours; then dry them at 100°C for 24 hours and pre-fire them. The heating rate of ℃ / min is raised to 940 ℃, kept for 4 hours, and cooled naturally with the furnace; the pre-fired powder is planetary ball milled for 4 hours, and then dried at 100 ℃ for 24 hours to obtain ceramic powder;

[0054] (3) Add polyvinyl alcohol aqueous solution to the ceramic powder, its concentration is 5wt.%, the addition is 3% of ceramic powder mass, mix and granulate, cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com