Special camphor growth fertilizer and preparation method thereof

A technology of fertilizer and camphor, which is applied in the field of special growth fertilizer for camphor, can solve the problems of no camphor fertilizer, slow growth of camphor, and failure to meet people's use needs, so as to reduce the rate of pests and diseases, promote growth, and high fertilizer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

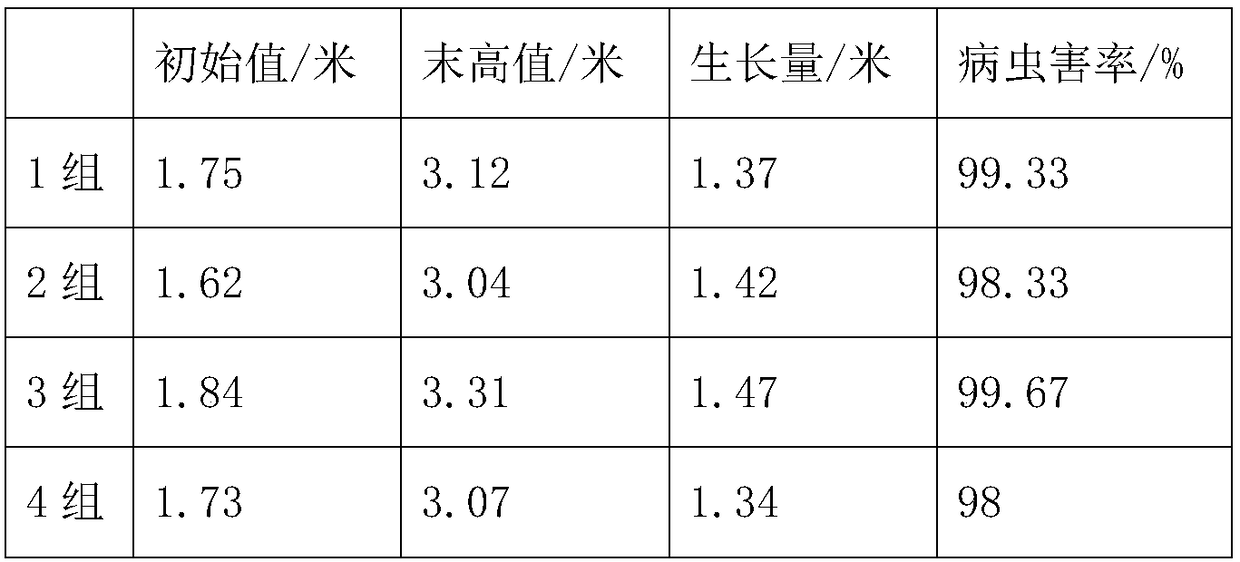

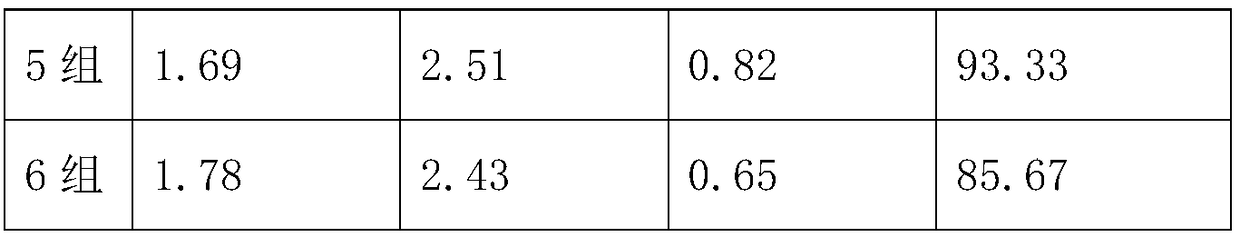

Examples

Embodiment 1

[0023] A special growth fertilizer for camphor, comprising the following raw materials in parts by weight: 24 parts of Kuding tea dregs, 10.5 parts of seabuckthorn dregs, 8 parts of raw ground dregs, 75 parts of straw, 38.2 parts of beer dregs, 15 parts of rapeseed meal, 17 parts of shrimp shell powder 2.5 parts of carotene, 2 parts of potassium fulvic acid and 2.8 parts of compound bacteria. Straw includes a mixture of corn stover, soybean straw and rice straw.

[0024] The preparation method of the special growth fertilizer for camphor camphora, the concrete steps are as follows:

[0025] Step 1: Soak the seabuckthorn slag in water at 82 degrees Celsius that is 5 times its weight, and extract it three times with ultrasonic waves. The power of the ultrasonic extraction is 115W, the frequency is 28KHz, and each time is 44 minutes. Filter and concentrate to obtain the seabuckthorn concentrate;

[0026] Step 2, carbonize the straw in a carbonization furnace and pass through a 1...

Embodiment 2

[0032] A special growth fertilizer for camphor, comprising the following raw materials in parts by weight: 29.5 parts of Kuding tea dregs, 13.3 parts of seabuckthorn dregs, 10.5 parts of raw ground dregs, 81.4 parts of straw, 40.6 parts of beer dregs, 19.8 parts of rapeseed meal, 18.8 parts of shrimp shell powder 2.9 parts of carotene, 2.4 parts of potassium fulvic acid and 3.5 parts of compound bacteria. The particle size of shrimp shell powder is 0.35mm.

[0033] The preparation method of the special growth fertilizer for camphor camphora, the concrete steps are as follows:

[0034] Step 1: Soak the seabuckthorn slag in water at 84 degrees Celsius that is 6 times its weight, ultrasonically extract it 4 times, each time for 48 minutes, filter and concentrate to obtain the seabuckthorn concentrate;

[0035] Step 2, carbonize the straw in a carbonization furnace and pass through a 200-mesh sieve to obtain biochar;

[0036] Step 3: enzymatically hydrolyze the raw land slag at ...

Embodiment 3

[0041] A special growth fertilizer for camphor, comprising the following raw materials in parts by weight: 35.6 parts of Kuding tea dregs, 15.2 parts of sea buckthorn dregs, 11.8 parts of raw ground dregs, 85.3 parts of straw, 42.6 parts of beer dregs, 21.4 parts of rapeseed meal, 21.2 parts of shrimp shell powder 3.4 parts of carotene, 2.8 parts of potassium fulvic acid and 4.4 parts of compound bacteria. Straw includes a mixture of corn stover, sugar cane straw, sorghum straw and rice straw. The particle size of shrimp shell powder is 0.45mm.

[0042] The preparation method of the special growth fertilizer for camphor camphora, the concrete steps are as follows:

[0043] Step 1: Soak the seabuckthorn slag in water at 80 degrees Celsius that is 6 times its weight, ultrasonically extract it 4 times, 48 minutes each time, filter and concentrate to obtain the seabuckthorn concentrate;

[0044] Step 2, carbonize the straw in a carbonization furnace and pass through a 160-mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com