Surface treatment solution and surface treatment device for SLM (selective laser melting) modeled stainless steel parts

A surface treatment liquid, stainless steel technology, applied in the direction of process efficiency improvement, additive manufacturing, energy efficiency improvement, etc., can solve the problems of inability to process parts, high labor intensity, high cost, and achieve easy assembly, simple configuration, and bright surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

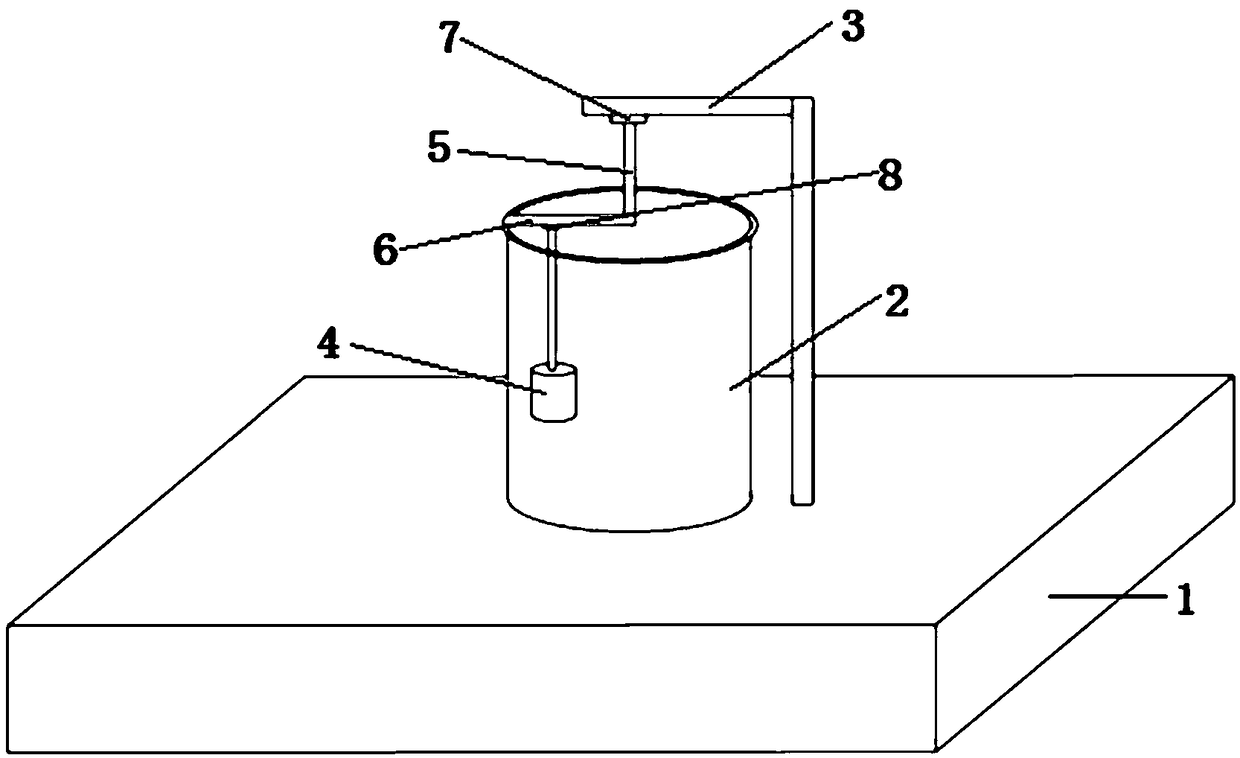

Method used

Image

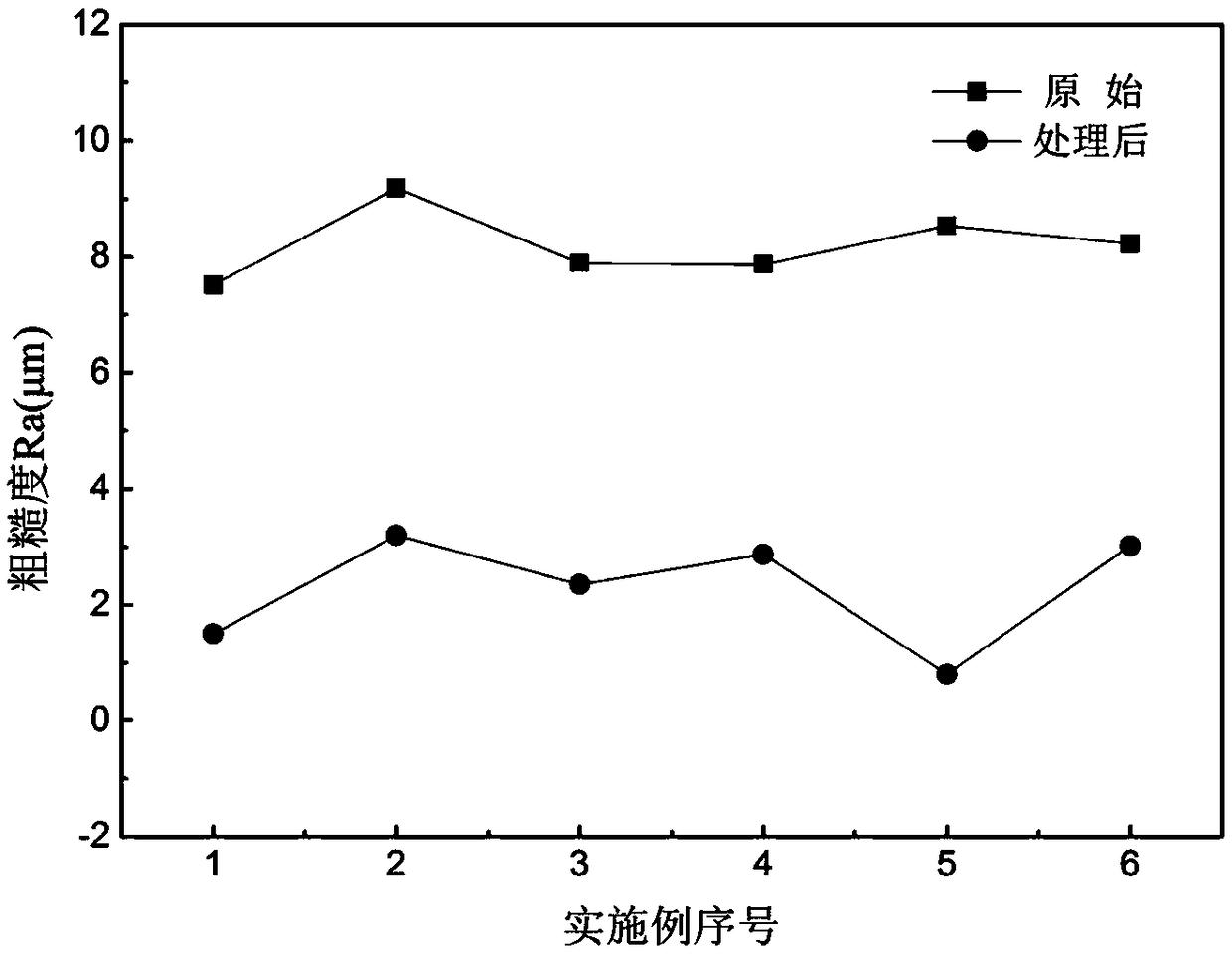

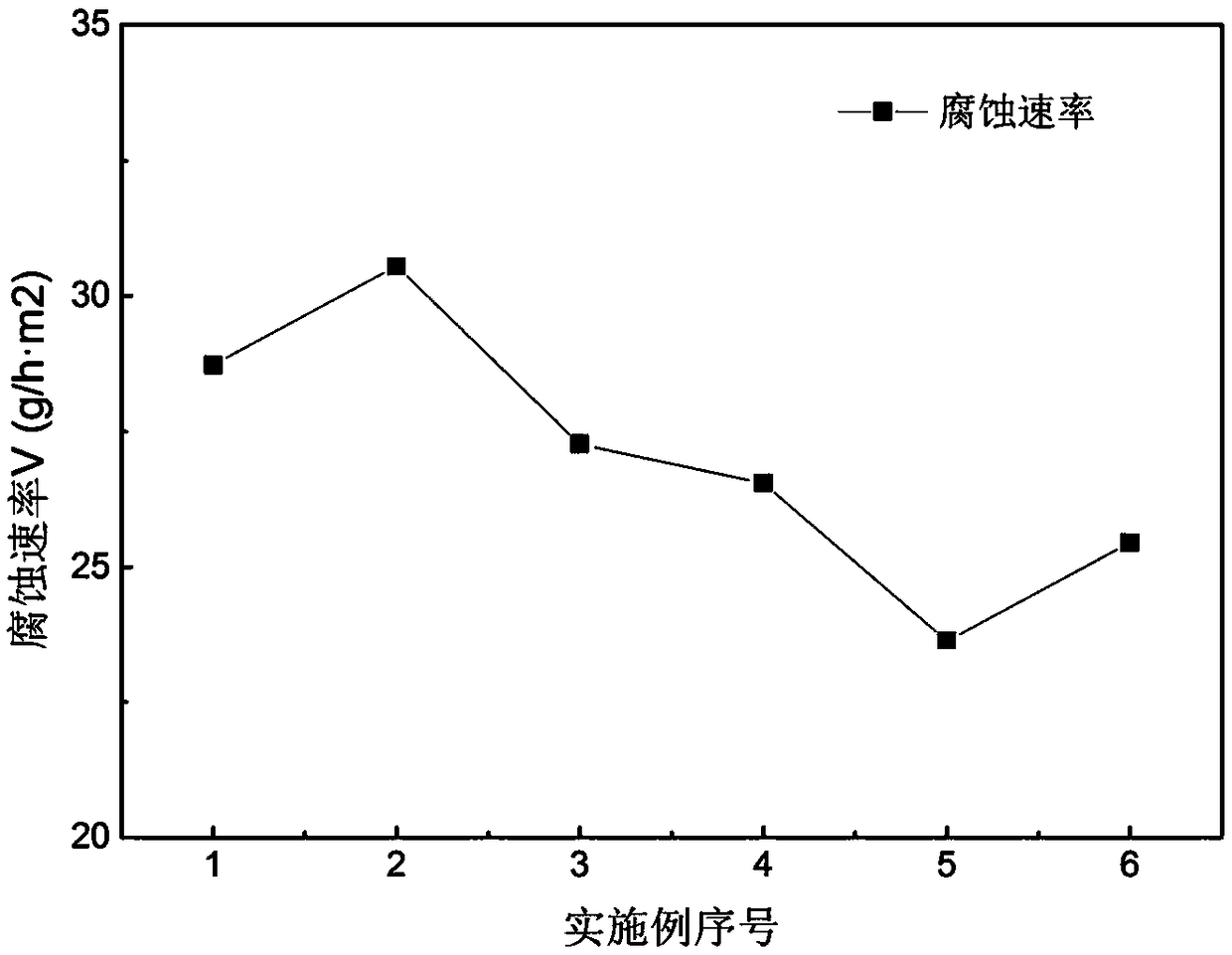

Examples

Embodiment 1

[0060] A surface treatment solution for SLM formed stainless steel parts, including alkaline solution, pickling solution and chemical polishing solution:

[0061] The mass-number ratio of potassium hydroxide, oxidizing agent and sodium chloride in the alkaline solution is 14:12:1.

[0062] The oxidizing agent is composed of sodium nitrate and potassium permanganate, and the mass-number ratio of sodium nitrate and potassium permanganate is 0.8:1.

[0063] The pickling liquid is composed of sodium chloride, hydrochloric acid and sulfuric acid, and the mass-number ratio of sodium chloride, hydrochloric acid and sulfuric acid is 12:4:1.

[0064] Chemical polishing liquid is made up of colloidal silicon dioxide, zirconia, 68wt% nitric acid, 36wt% hydrochloric acid, 85%wt phosphoric acid, 98%wt sulfuric acid, viscosity regulator, corrosion inhibitor, brightener, fog suppressant and water; The mass parts ratio of silicon oxide, zirconia, 68wt% nitric acid, 36wt% hydrochloric acid, 8...

Embodiment 2

[0088] Embodiment 2 comprises the solution preparation step of embodiment 1, surface treatment device and experimental process, and the surface treatment liquid of embodiment 2 comprises alkali boiling liquid, pickling liquid and chemical polishing liquid:

[0089] The mass-number ratio of potassium hydroxide, oxidizing agent and sodium chloride in the alkaline solution is 16:15:1.

[0090]The oxidizing agent is composed of sodium nitrate and potassium permanganate, and the mass-number ratio of sodium nitrate and potassium permanganate is 0.7:1.

[0091] The pickling liquid is made up of sodium chloride, hydrochloric acid and sulfuric acid, and the mass-number ratio of sodium chloride, hydrochloric acid, sulfuric acid is 5: 4: 1;

[0092] The mass parts ratio of colloidal silicon dioxide, zirconia, 68wt% nitric acid, 36wt% hydrochloric acid, 85%wt phosphoric acid, 98%wt sulfuric acid, viscosity regulator, corrosion inhibitor, brightener, fog suppressant and water is as follows...

Embodiment 3

[0104] Embodiment 3 comprises the solution preparation step of embodiment 1, surface treatment device and experimental process, and the surface treatment liquid of embodiment 3 comprises alkali boiling liquid, pickling liquid and chemical polishing liquid:

[0105] The mass-number ratio of potassium hydroxide, oxidizing agent and sodium chloride in the alkaline solution is 18:10:1.

[0106] The oxidizing agent is composed of sodium nitrate and potassium permanganate, and the mass-number ratio of sodium nitrate and potassium permanganate is 0.5:1.

[0107] The mass-number ratio of sodium chloride, hydrochloric acid, and sulfuric acid in the pickling solution is 12:5:1;

[0108] Mass parts of colloidal silicon dioxide, zirconia, 68wt% nitric acid, 36wt% hydrochloric acid, 85%wt phosphoric acid, 98%wt sulfuric acid, viscosity modifier, corrosion inhibitor, brightener, fog suppressor and water in chemical polishing liquid For example: 2:8:4.5:5:3.5:2:1:0.25:0.15:0.005:15.

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com