A vertical cavity surface emitting silicon substrate GaN laser based on a dielectric Bragg mirror and a preparation method thereof

A technology of Bragg reflector and vertical cavity surface emission, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of complex process, time-consuming and difficult to obtain high quality of semiconductor Bragg reflectors, and achieve the benefit of large-scale The effect of mass production, excellent thermal and electrical conductivity, and easy substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

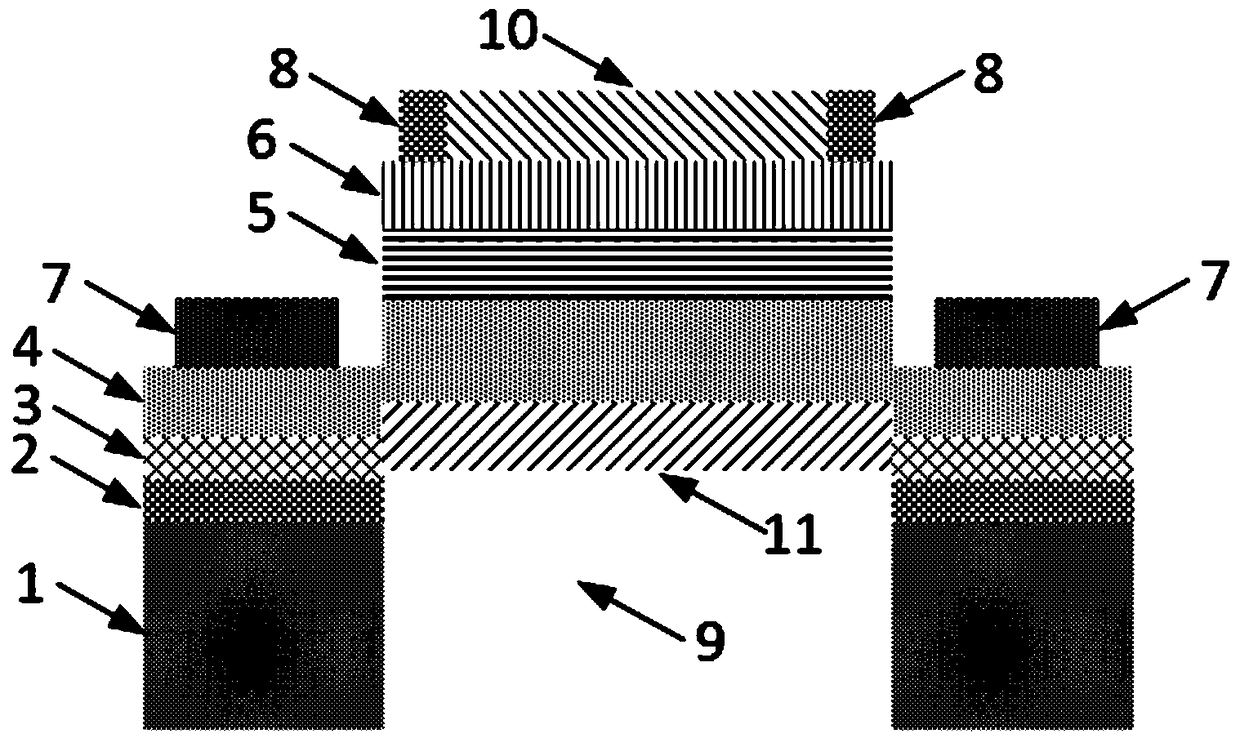

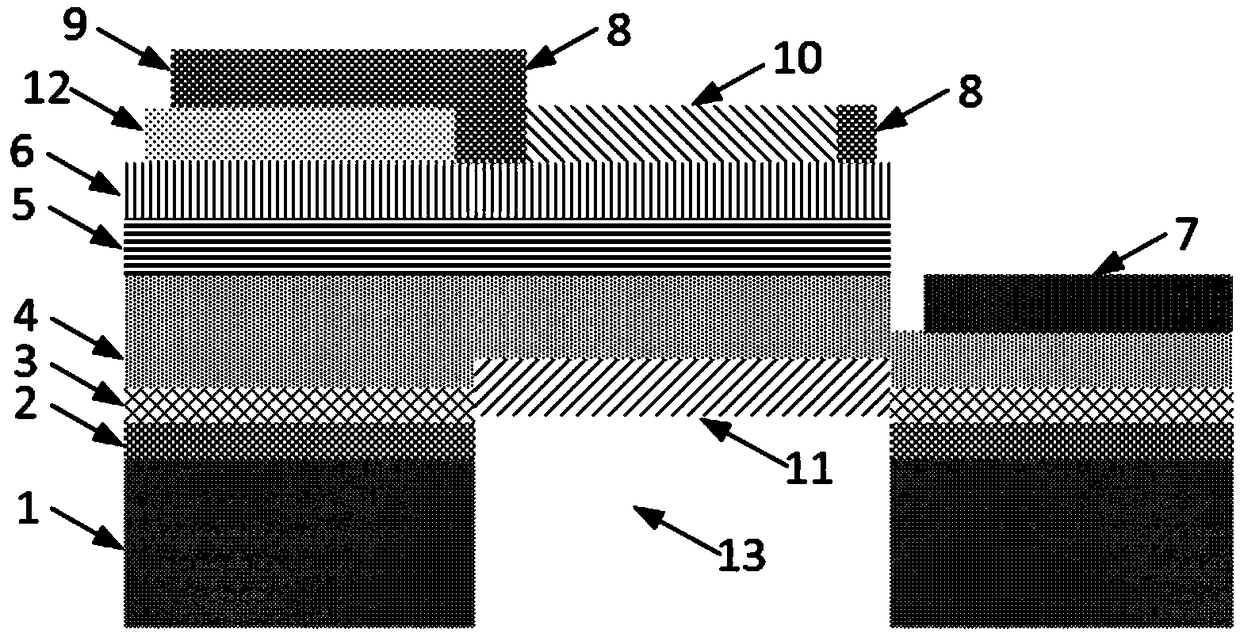

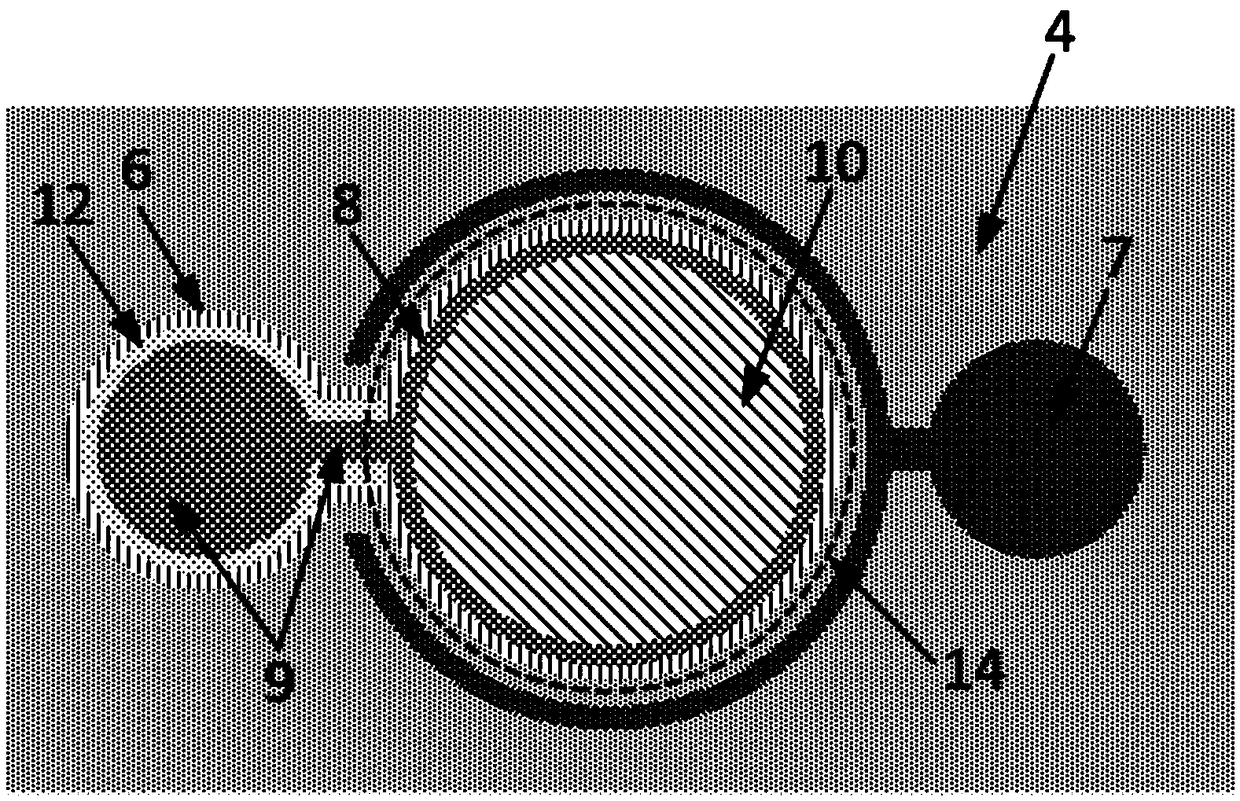

[0038] Such as figure 1 , figure 2 with image 3 As shown, a vertical cavity surface emitting silicon substrate GaN laser based on a dielectric Bragg mirror uses a silicon substrate nitride wafer as a carrier, including a silicon substrate layer 1, an AlN layer 2 disposed on the silicon substrate layer 1, An AlGaN layer 3 disposed on the AlN layer 2 , a vertical resonant microcavity 14 disposed on the AlGaN layer 3 , an insulating isolation layer 12 , an n-type electrode 7 and a p-type electrode.

[0039] The vertical resonant microcavity 14 is composed of an n-GaN layer 4, an InGaN multi-quantum well layer 5 disposed on the n-GaN layer 4, a p-GaN layer 6 disposed on the InGaN multi-quantum well layer 5, and a p-GaN multi-quantum well layer disposed on the p-GaN layer 6 and a bottom mirror 11 disposed on the lower surface of the n-GaN layer 4. The p-type electrode is composed of the connected p-type electrode conductive region 8 and p-type electrode bonding region 9 . The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com