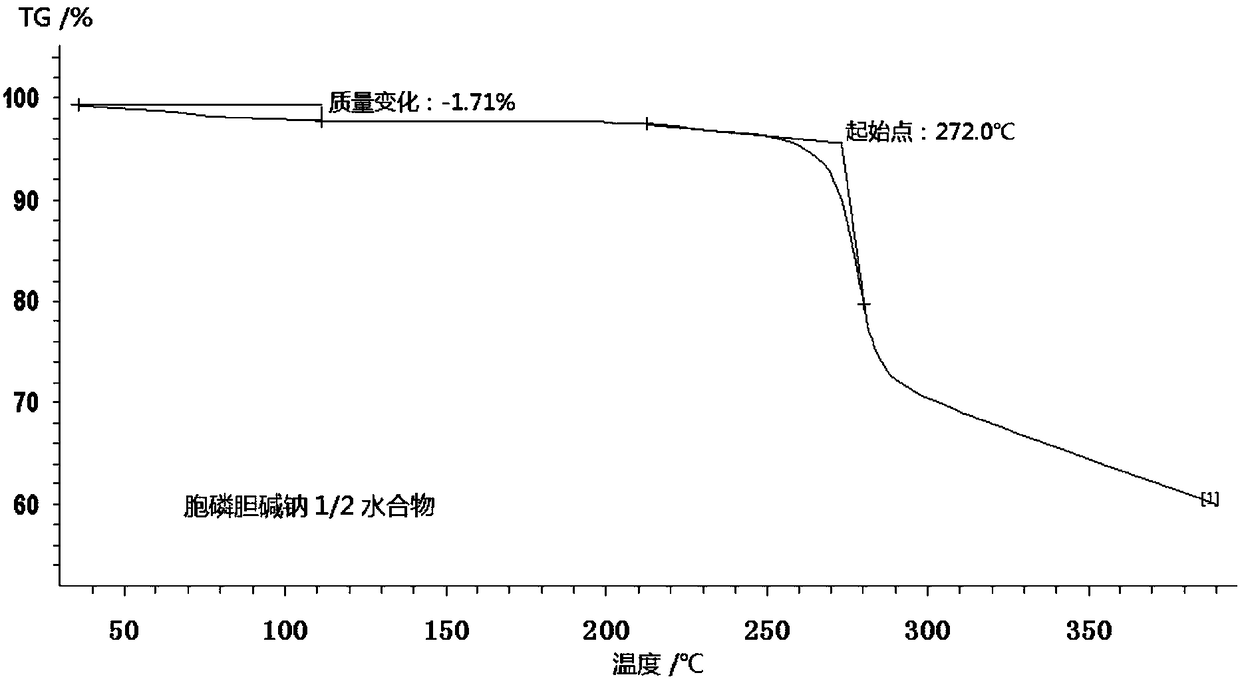

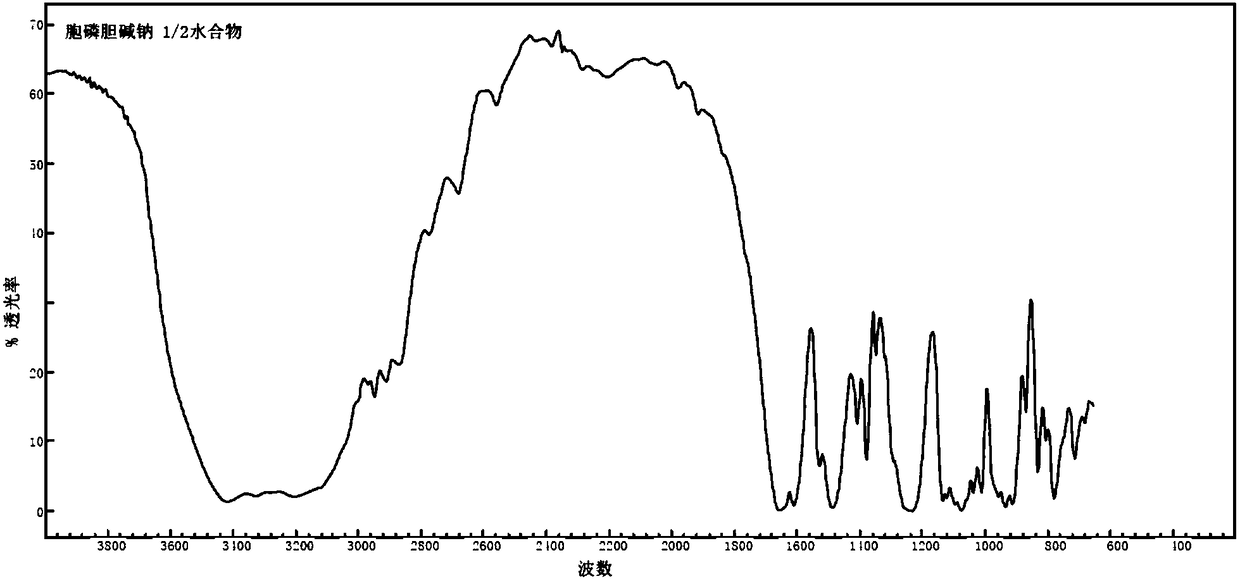

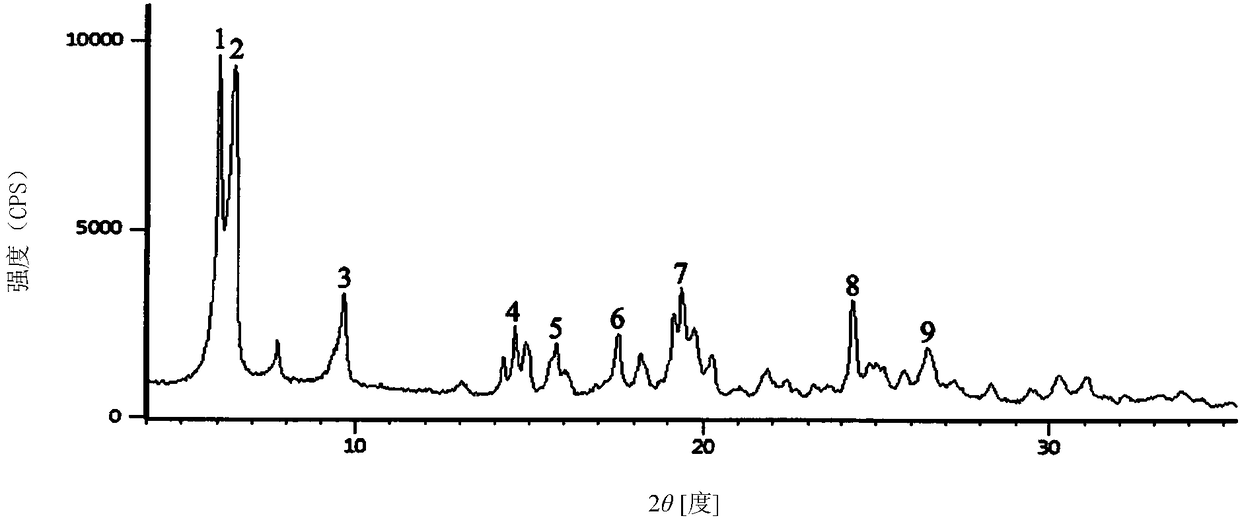

1/2 water citicoline sodium compound

A technology of citicoline sodium and compound, applied in the field of 1/2 water citicoline sodium compound and its preparation method, can solve the problems of poor product quality, waste of manpower, material resources, financial resources, competition and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of 1 / 2 water citicoline sodium compound

[0031] Preparation Process:

[0032] Add 100 mL of purified water and 300 mL of acetone to the reactor and stir evenly. Weigh 100.11 g of the crude citicoline sodium, 0.10 g of calcium sodium edetate, and 0.10 g of sodium sulfite into the reactor, and stir at room temperature until dissolved. Add 0.25 g of activated carbon to it, stir and absorb for 30 min, and filter. Adjust the pH value of the filtrate to 2.0 with a 1mol / L hydrochloric acid solution, control the temperature at 15-20℃, slowly add 125 mL of isopropanol to the above solution, and control the temperature at 5-10℃ after the addition of isopropanol is complete. Let stand for 1.5h to crystallize, filter, wash the filter with isopropanol 80mL×2, put the filter into a vacuum drying oven (-0.09MPa) with phosphorus pentoxide for 24h, then heat to 60℃ and dry for 2.5h , Get 1 / 2 water citicoline sodium compound 96.21g.

[0033] result:

[0034] The infra...

Embodiment 2

[0037] Example 2: Preparation of 1 / 2 water citicoline sodium compound

[0038] Preparation Process:

[0039] Add 100 mL of purified water and 400 mL of acetone to the reactor and stir evenly. Weigh 100.05 g of the crude citicoline sodium, 0.12 g of calcium sodium edetate, and 0.12 g of sodium sulfite into the reactor, and stir at room temperature until dissolved. 0.31g of activated carbon was added to it, stirred and adsorbed for 30 minutes, and filtered. Adjust the pH value of the filtrate to 1.5 with 1mol / L hydrochloric acid solution, control the temperature at 15-20℃, slowly add 160mL of isopropanol to the above solution, when the isopropanol dripping is completed, control the temperature at 0-5℃ , Stand for 1h to crystallize, filter, wash the filter with isopropanol 80mL×2, put the filter into a vacuum drying oven (-0.09MPa) with phosphorus pentoxide for 24h, then heat to 70℃ and dry for 2h, 95.79 g of 1 / 2 water citicoline sodium compound was obtained.

[0040] result:

[0041...

Embodiment 3

[0044] Example 3: Preparation of Citicoline Sodium Lyophilized Preparation

[0045] Take the 1 / 2 water citicoline sodium compound prepared in Example 2, and use this raw material to prepare a citicoline sodium lyophilized preparation with a specification of 0.25 g.

[0046] prescription:

[0047]

[0048] Preparation Process:

[0049] 1. Liquid preparation

[0050] (1) Add 80% of the prescribed amount of water for injection into the dispensing tank;

[0051] (2) Add 1 / 2 of the prescription amount of citicoline sodium compound, stir to dissolve completely, and add water for injection to the full amount;

[0052] (3) Add 0.05% medicinal charcoal (for injection) to the medicinal solution, stir and absorb for 15 minutes;

[0053] (4) Filter and decarburize with 0.45μm filter membrane;

[0054] (5) Filter and decarburize with 0.22μm filter membrane.

[0055] 2. Filling: Fill in a medium borosilicate glass tubular injection bottle according to the theoretical filling volume, and press half the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com