A kind of polytetrafluoroethylene graft film and preparation method thereof

A technology of polytetrafluoroethylene and film, which is applied in the field of polytetrafluoroethylene grafted film and its preparation, can solve the problems of limited improvement of surface free energy and complicated treatment, and achieve simple post-processing steps and simple reaction system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

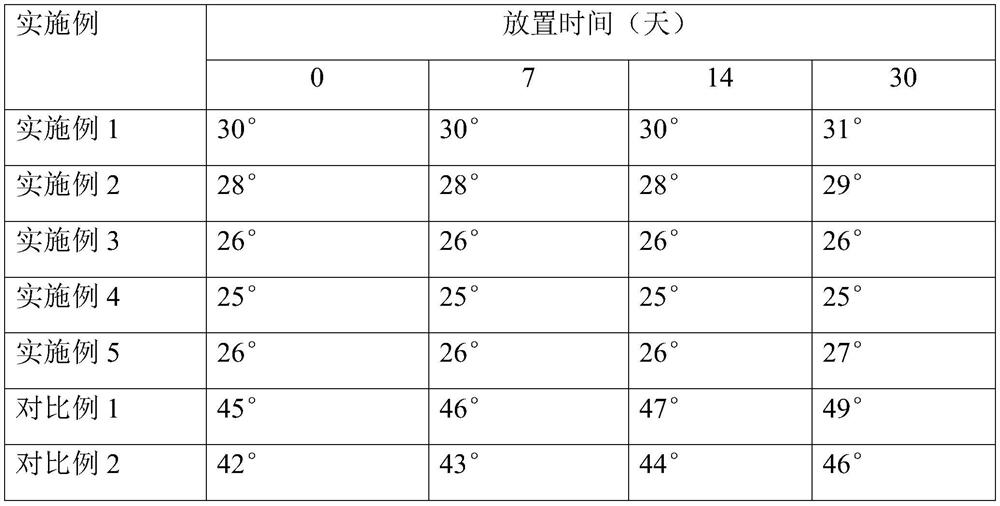

Examples

Embodiment 1

[0030] The preparation method of a kind of polytetrafluoroethylene graft film of the present embodiment comprises the following steps:

[0031] (1) Put the polytetrafluoroethylene powder into a mold for cold pressing, then sinter in a sintering furnace at 370-390°C, and turn the sintered green body into a 0.01-10mm polytetrafluoroethylene film on a rotary cutter;

[0032] The polytetrafluoroethylene film can also be selected from commercially available ready-made polytetrafluoroethylene films;

[0033] Put the polytetrafluoroethylene film in the plasma treatment equipment for single-sided or double-sided plasma treatment, the treatment power is 100W, and the treatment time is 90s;

[0034] (2) Place the plasma-treated polytetrafluoroethylene film in the reactor, feed nitrogen into the reactor to discharge oxygen, after the oxygen is exhausted, feed anhydrous tetrahydrofuran, N-(benzene and cyclobutene-4-yl) the mixed solution of maleimide and acrylic acid, the feed rate of th...

Embodiment 2

[0038] The preparation method of a kind of polytetrafluoroethylene graft film of the present embodiment comprises the following steps:

[0039] (1) Put the polytetrafluoroethylene powder into a mold for cold pressing, then sinter in a sintering furnace at 370-390°C, and turn the sintered green body into a 0.01-10mm polytetrafluoroethylene film on a rotary cutter;

[0040] The polytetrafluoroethylene film can also be selected from commercially available ready-made polytetrafluoroethylene films;

[0041]Put the polytetrafluoroethylene film in the plasma treatment equipment for single-sided or double-sided plasma treatment, the treatment power is 100W, and the treatment time is 90s;

[0042] (2) Place the plasma-treated polytetrafluoroethylene film in the reactor, feed nitrogen into the reactor to discharge oxygen, after the oxygen is exhausted, feed anhydrous tetrahydrofuran, N-(benzene and cyclobutene-4-yl) the mixed solution of maleimide and acrylic acid, the feed rate of the...

Embodiment 3

[0046] The preparation method of a kind of polytetrafluoroethylene graft film of the present embodiment comprises the following steps:

[0047] (1) Put the polytetrafluoroethylene powder into a mold for cold pressing, then sinter in a sintering furnace at 370-390°C, and turn the sintered green body into a 0.01-10mm polytetrafluoroethylene film on a rotary cutter;

[0048] The polytetrafluoroethylene film can also be selected from commercially available ready-made polytetrafluoroethylene films;

[0049] Put the polytetrafluoroethylene film in the plasma treatment equipment for single-sided or double-sided plasma treatment, the treatment power is 100W, and the treatment time is 90s;

[0050] (2) Place the plasma-treated polytetrafluoroethylene film in the reactor, feed nitrogen into the reactor to discharge oxygen, after the oxygen is exhausted, feed anhydrous tetrahydrofuran, N-(benzene and cyclobutene-4-yl) the mixed solution of maleimide and acrylic acid, the feed rate of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com