Self-stabilized P(VDF-HFP) (Poly(Vinylidene Fluoride-Hexafluoropropylene)) slurry as well as preparation and lithium-ion battery separator thereof

A VDF-HFP, self-stabilizing technology, applied in the field of self-stabilizing P slurry and its preparation, can solve the problems of battery consistency, safety hazards, non-dispersion, etc., to improve performance and safety performance, promote dispersion, and improve surface The effect of free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

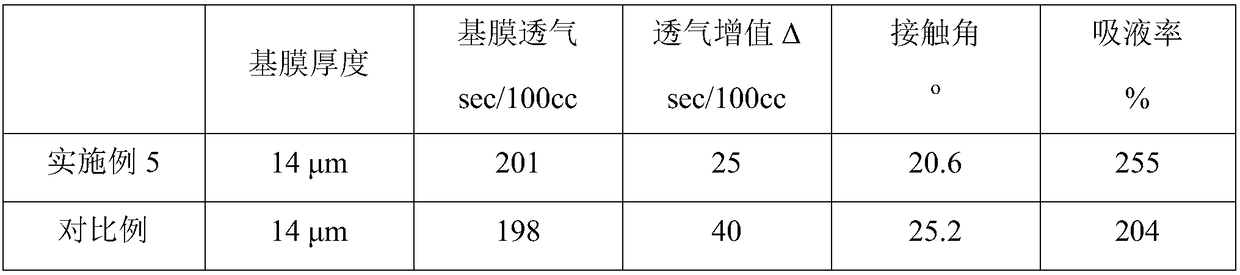

Examples

preparation example Construction

[0022] The invention discloses a preparation method of self-stabilizing P(VDF-HFP) slurry, comprising the following steps:

[0023] a. Add acrylic acid monomer and polymerization inhibitor to deionized water for mixing and dissolving, then add P(VDF-HFP) powder to obtain a mixed system;

[0024] b. Pass inert gas into the mixed system to get rid of the air in the mixed system, and then keep it sealed;

[0025] c. Put the mixed system sealed and preserved in step b into 60 Irradiate in a Coγ-ray irradiation device to obtain a dispersion;

[0026] d. After the dispersion liquid is centrifuged and washed with water, it is redispersed in deionized water to prepare a self-stabilizing P(VDF-HFP) slurry.

[0027] Make self-stabilizing P (VDF-HFP) slurry by the preparation method among the present invention, on the one hand because its surface is grafted with PAA, therefore can serve as dispersant, promotes P (VDF-HFP) microsphere well in water Dispersion; on the other hand, the gr...

Embodiment 1

[0038] a. Add 5g of acrylic acid monomer and 0.25g of ferrous sulfate heptahydrate into 50ml of deionized water to mix and dissolve, then add 1.5g of P(VDF-HFP) powder to obtain a mixed system;

[0039] b. Infuse nitrogen into the mixing system for 30 minutes to remove the air in the mixing system, and then seal it for storage;

[0040] c. Put the mixed system sealed and preserved in step b into 60 In the Coγ-ray irradiation device, the irradiation dose rate is 9Gy / min for 24h, and the total absorbed dose of irradiation is 13kGy to obtain the dispersion liquid;

[0041] d. After the dispersion liquid was centrifuged and washed 6 times, it was redispersed in 30ml deionized water to make a self-stabilizing P(VDF-HFP) slurry with a solid content of 1%;

[0042] f. Coat the self-stabilizing P (VDF-HFP) slurry on the surface of polyolefin or polyolefin separator coated with ceramics using a micro gravure roll to obtain a lithium-ion battery separator with a coating thickness of 0....

Embodiment 2

[0044] a. Add 15g of acrylic acid monomer and 0.5g of copper sulfate into 100ml of deionized water to mix and dissolve, then add 4g of P(VDF-HFP) powder to obtain a mixed system;

[0045] b. Infuse nitrogen gas into the mixing system for 25 minutes to remove the air in the mixing system, and then seal it for storage;

[0046] c. Put the mixed system sealed and preserved in step b into 60In the Coγ-ray irradiation device, the irradiation dose rate is 6Gy / min for 40h, and the total absorbed dose of irradiation is 50kGy to obtain the dispersion liquid;

[0047] d. After the dispersion liquid was centrifuged and washed 5 times, it was redispersed in 40ml deionized water to make a self-stabilizing P(VDF-HFP) slurry with a solid content of 5%;

[0048] f. Coat the self-stabilizing P (VDF-HFP) slurry on the surface of polyolefin or polyolefin separator coated with ceramics by micro gravure roll to obtain lithium ion battery separator, the coating thickness is 1 μm, and the coated su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com