Flexible strain sensor capable of responding ultrafast, and preparation method thereof

A strain sensor and flexible technology, applied in the field of sensors, can solve the problems of large gaps and restrictions on the application of flexible sensors, and achieve the effects of compact stacking, sensitive transmission of stress/strain waves, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

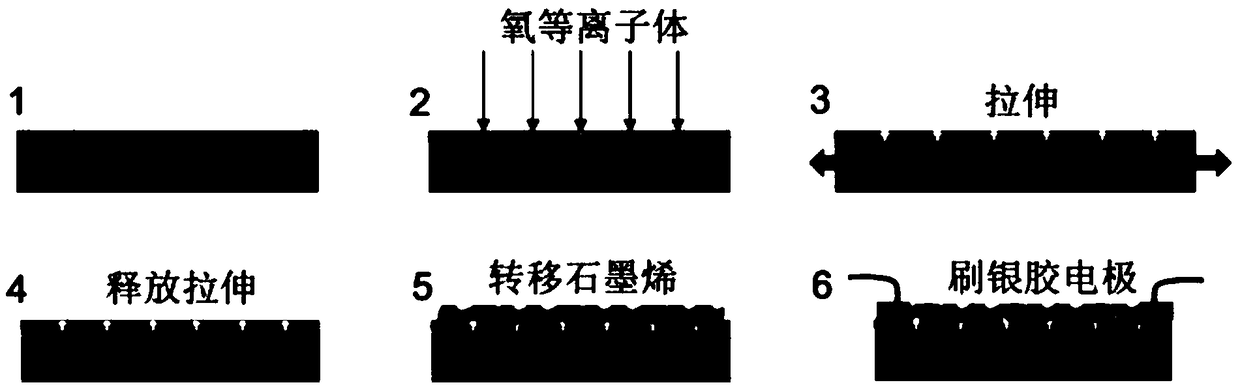

[0036] The invention provides a method for preparing an ultrafast response flexible strain sensor, comprising the following steps:

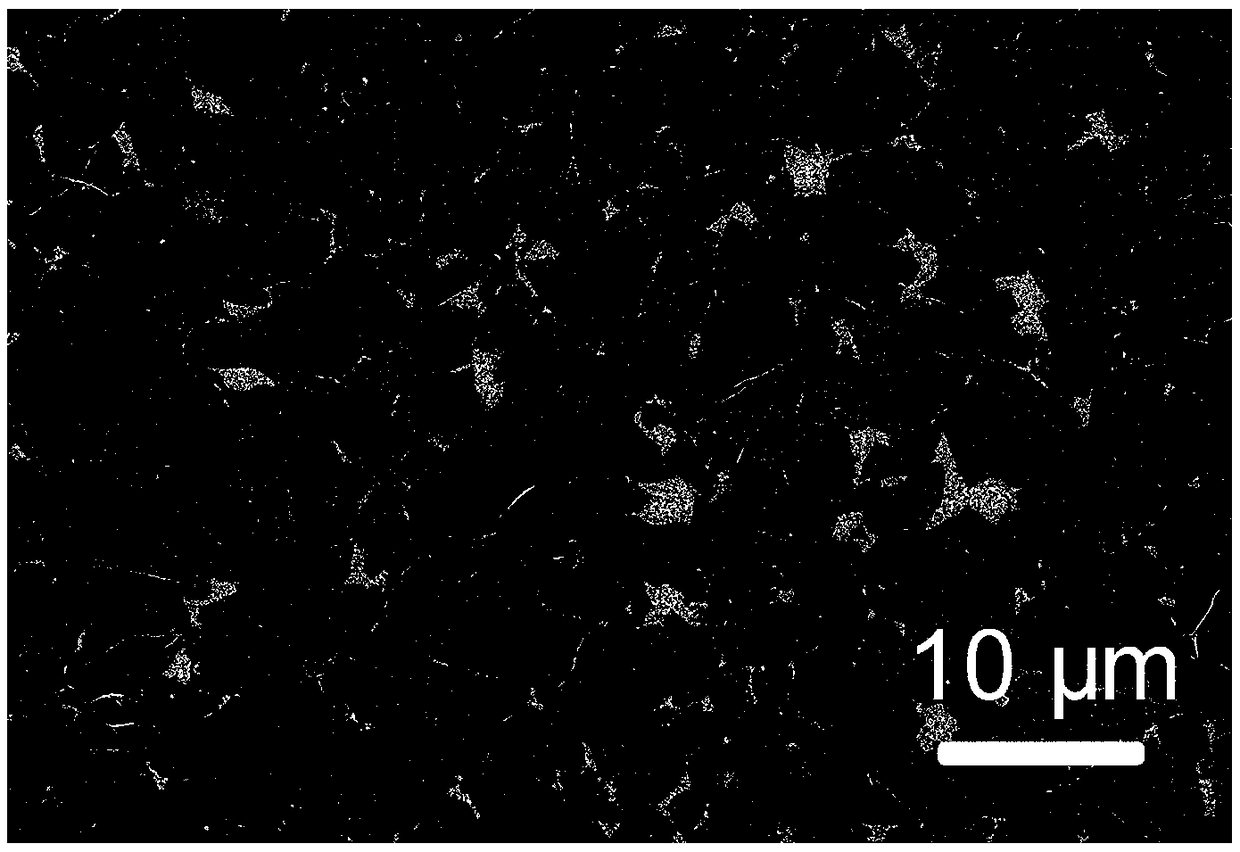

[0037] (1) modifying the surface of the flexible substrate, and then stretching the obtained modified flexible substrate to form a penetrating long crack on the surface of the modified flexible substrate;

[0038] (2) coating the functionalized graphene dispersion on the surface of the stretched flexible substrate in step (1) to form a functionalized graphene film; the dispersion solvent of the graphene dispersion is N-methylpyrrolidone;

[0039] (3) reducing the functionalized graphene film to form a graphene sensitive layer;

[0040] (4) brushing conductive silver glue on both sides of the graphene sensitive layer and bonding wires to obtain a flexible strain sensor with ultra-fast response;

[0041] The response time of the flexible strain sensor with ultra-fast response is 50 μs˜500 μs.

[0042] The invention modifies the surface of the fle...

Embodiment 1

[0070] The substrate used in Example 1 is a self-prepared PDMS substrate. The preparation method is as follows: add polydimethylsiloxane elastomer and curing agent in a beaker at a mass ratio of 10:1, and stir evenly with a stirrer for 2 to 10 minutes , use a vacuum machine to repeatedly extract the air in the beaker until the bubbles in the PDMS mixture completely disappear, add an appropriate amount of PDMS mixture to the petri dish, and heat at a constant temperature of 60°C for 2 hours in a vacuum drying oven to generate polydimethylsiloxane with a thickness of 100 μm alkane film, cut the resulting polydimethylsiloxane into a substrate with a size of about 2cm×1cm, and set aside.

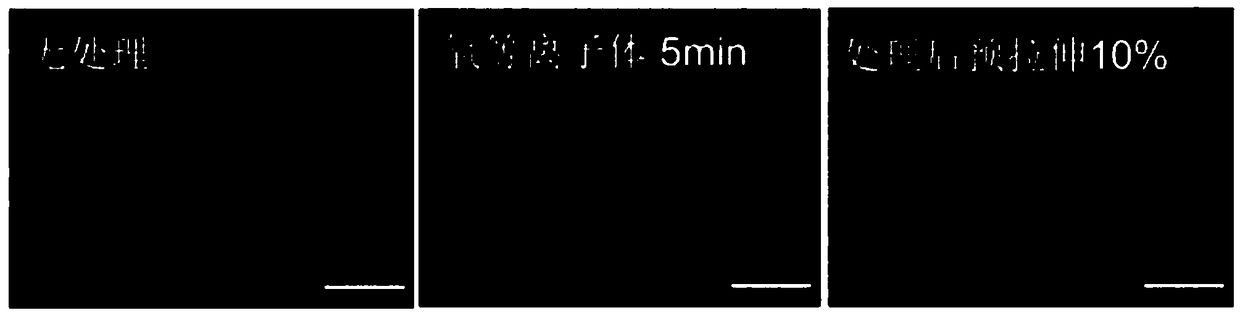

[0071] (1) Modification of the base layer:

[0072] Oxygen plasma treatment was performed on the surface of the substrate with a power of 300w, a gas flow rate of 40mL / min, and a time of 5min.

[0073] (2) Stretching of the substrate

[0074] After the aforementioned substrate modification tre...

Embodiment 2

[0087] Other steps are identical with embodiment 1, only change the modification of base layer in step (1) into chemical modification, modification process is as follows:

[0088] Attach the prepared PDMS substrate evenly to the surface of the glass slide, leaving a part of the upper end blank, clamp the blank space of the slide glass with a folder, put it in a petri dish for use, and weigh 0.248g of Tris medicine with a precision balance (trishydroxymethylaminomethane), transferred to a beaker, add 100g deionized water, and stir on a magnetic stirrer (400r / min) to configure the buffer. Add dilute hydrochloric acid dropwise to the sustained-release solution until the pH is 8.5 to provide a weakly alkaline environment for the growth of dopamine. Weigh 0.2476g of dopamine hydrochloride drug with a precision balance, pour it into the corrected buffer solution, then insert the glass slide with the substrate into the dopamine solution, place it on a magnetic stirrer (400r / min) and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Contact area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com