Preparation method of optical film of five-channel multicolor optical filter

A multi-color filter and optical film layer technology, which is applied in the field of optical film preparation of five-channel multi-color filter, can solve the problems of low yield, complex involvement, narrow coating area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred examples of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

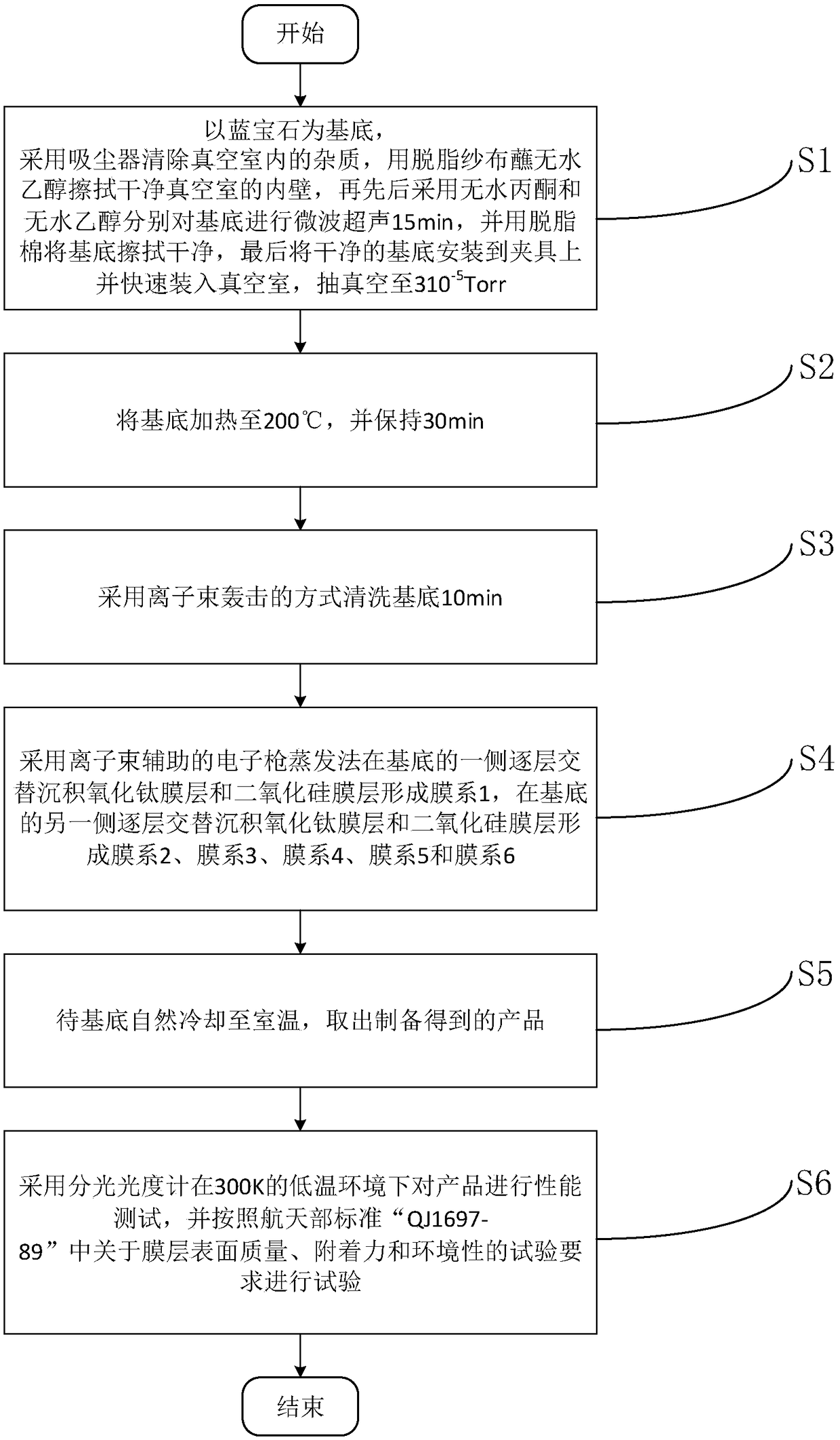

[0028] like figure 1 As shown, the optical film layer preparation method of the five-channel multicolor filter of the present invention is prepared by using a fully automatic optical coating machine system of Intergrity-39, using sapphire as the base to remove impurities in the vacuum chamber with a vacuum cleaner, and degreasing Wipe the inner wall of the vacuum chamber with gauze dipped in absolute ethanol, then microwave the substrate with anhydrous acetone and absolute ethanol for 15 minutes, and wipe the base with absorbent cotton, and finally install the clean substrate on the fixture and quickly put it into the vacuum chamber, evacuated to 3 x 10 -5 Torr, then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com