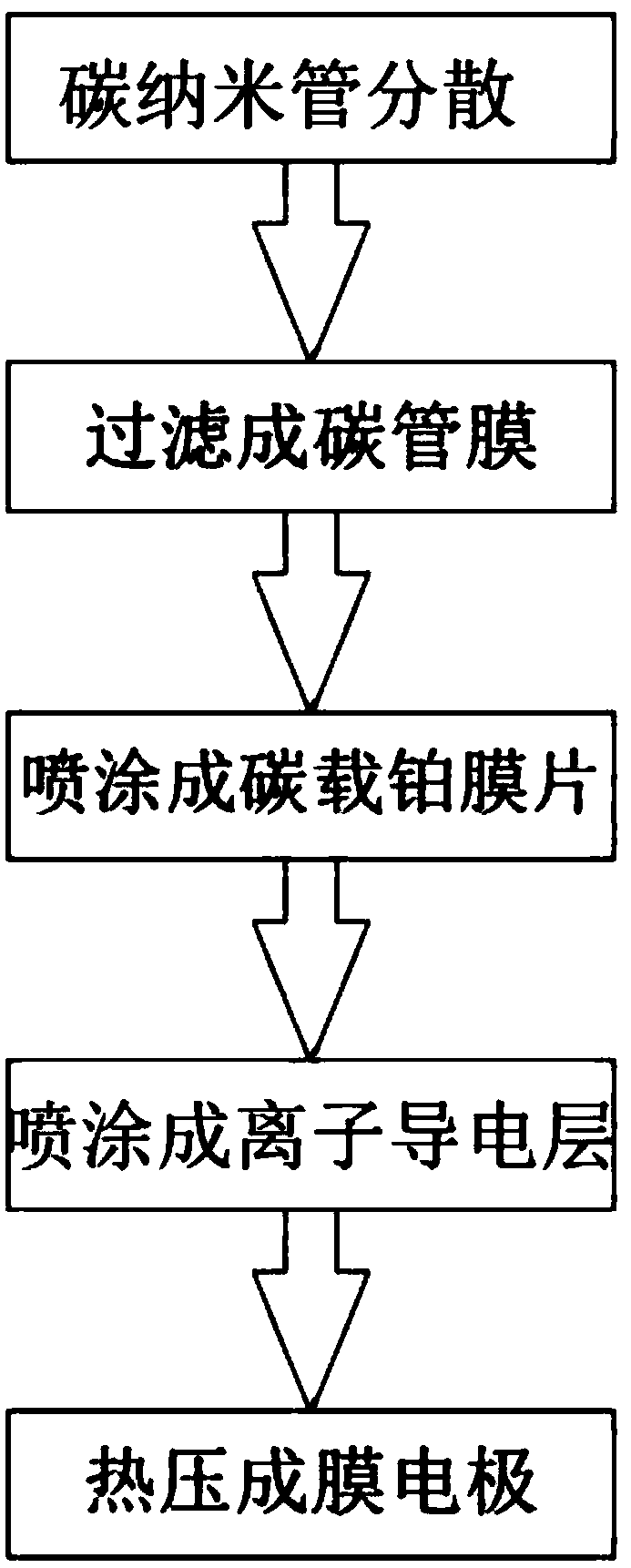

A method for preparing a membrane electrode using a carbon tube membrane as a carrier

A carbon tube membrane and membrane electrode technology, used in circuits, fuel cells, electrical components, etc., can solve the problems of difficult to completely remove residual impurity ions, difficult to uniform deposition of active metals, and changes in components in the membrane, to overcome the platinum utilization rate. Low effect, shortened proton transport path, and short reduction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

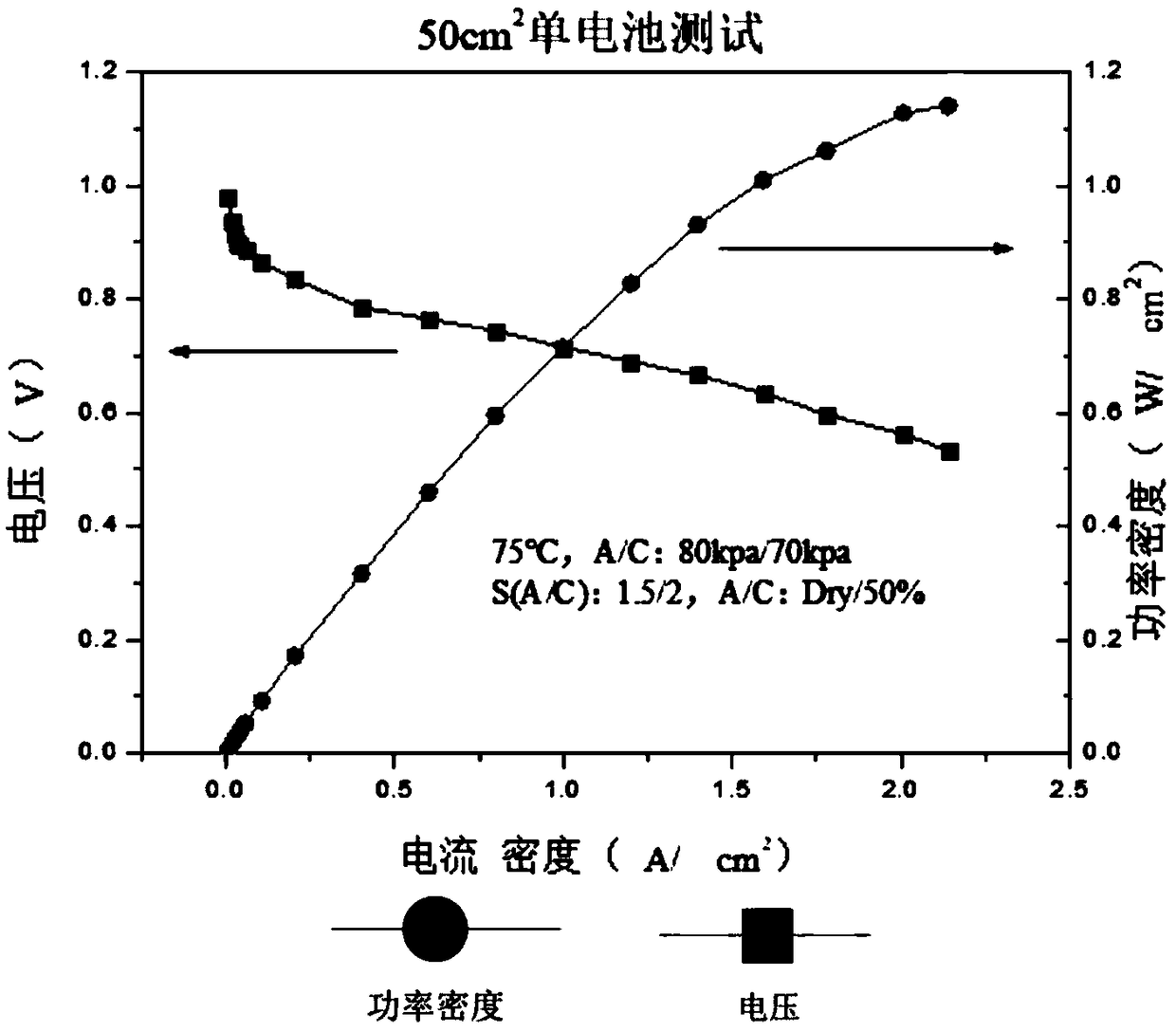

Examples

Embodiment 1

[0034] Preparation of cathode electrode pieces:

[0035] 1) Take 15 mg of carbon nanotube powder, add 5 g of ethanol, uniformly disperse by ultrasonic wave, and obtain a carbon tube film of 75×75 mm on the gas diffusion layer by means of pressure filtration.

[0036] 2) Fix the carbon tube film on the ultrasonic spraying machine, spray the chloroplatinic acid solution on the carbon tube film, place the sprayed carbon tube film in an atmosphere furnace of a hydrogen atmosphere (ambient temperature is 100° C.) and reduce it for 20min to obtain platinum The loading is 0.4mg / cm 2 carbon-supported platinum diaphragm.

[0037] 3) The perfluorosulfonic acid solution and isopropanol are prepared into an ionic conductor solution with a perfluorosulfonic acid content of 3%, mixed evenly, and the ionic conductor solution is sprayed on the carbon-supported platinum diaphragm by an ultrasonic sprayer, and dried to form Ion conductor layer, the spray loading of the ion conductor layer is ...

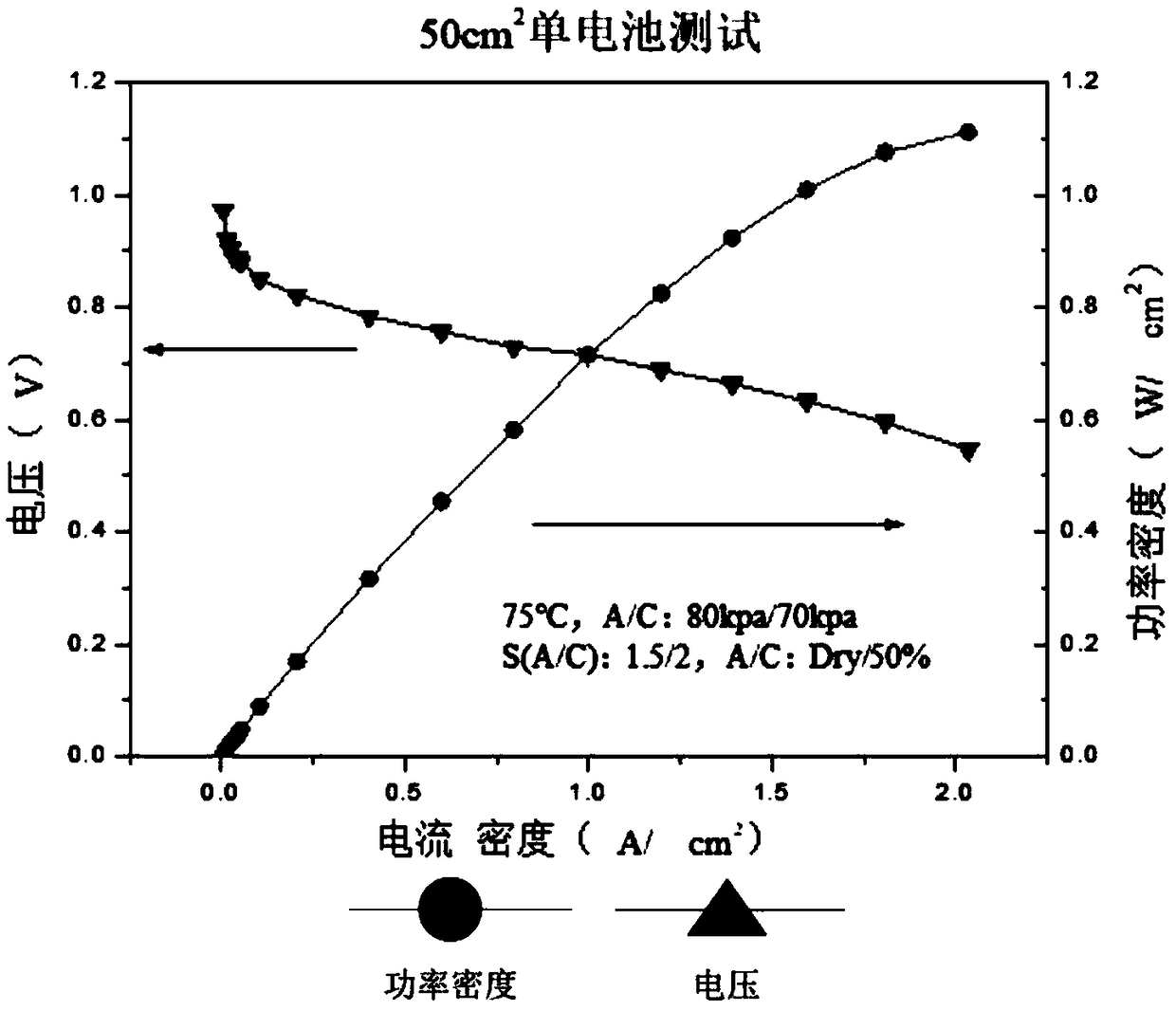

Embodiment 2

[0044] Preparation of cathode electrode pieces:

[0045] 1) Take 15 mg of carbon nanotube powder, add 5 g of propanol, uniformly disperse by means of high-speed shearing, and obtain a carbon tube film of 75×75 mm on the gas diffusion layer by means of pressure filtration.

[0046] 2) Fix the carbon tube film on the ultrasonic sprayer, spray a mixed solution of chloroplatinic acid and ruthenium trichloride (Pt: Ru=3:1) on the carbon tube film, and place the sprayed carbon tube film in a hydrogen atmosphere ( The ambient temperature is 230 ℃) in the atmosphere furnace for 20min reduction, and the platinum loading is 0.3mg / cm 2 carbon-supported platinum diaphragm.

[0047]3) The perfluorosulfonic acid solution and isopropanol are prepared into an ionic conductor solution with a perfluorosulfonic acid content of 3%, mixed evenly, and the ionic conductor solution is sprayed on the carbon-supported platinum diaphragm by an ultrasonic sprayer, and dried to form Ion conductor layer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com