Gradient 3D (three-dimensional) printing Ti-PDA-BMP-2 bone defect repairing stent and preparation method thereof

A BMP-2, ti-pda-bmp-2 technology, applied in the field of bone tissue repair and reconstruction, can solve the problems of unguaranteed biological safety, high price, allergic reactions, etc., and achieve good bone ingrowth characteristics and Effects of biosafety, improved hydrophilicity and biocompatibility, and improved carrying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

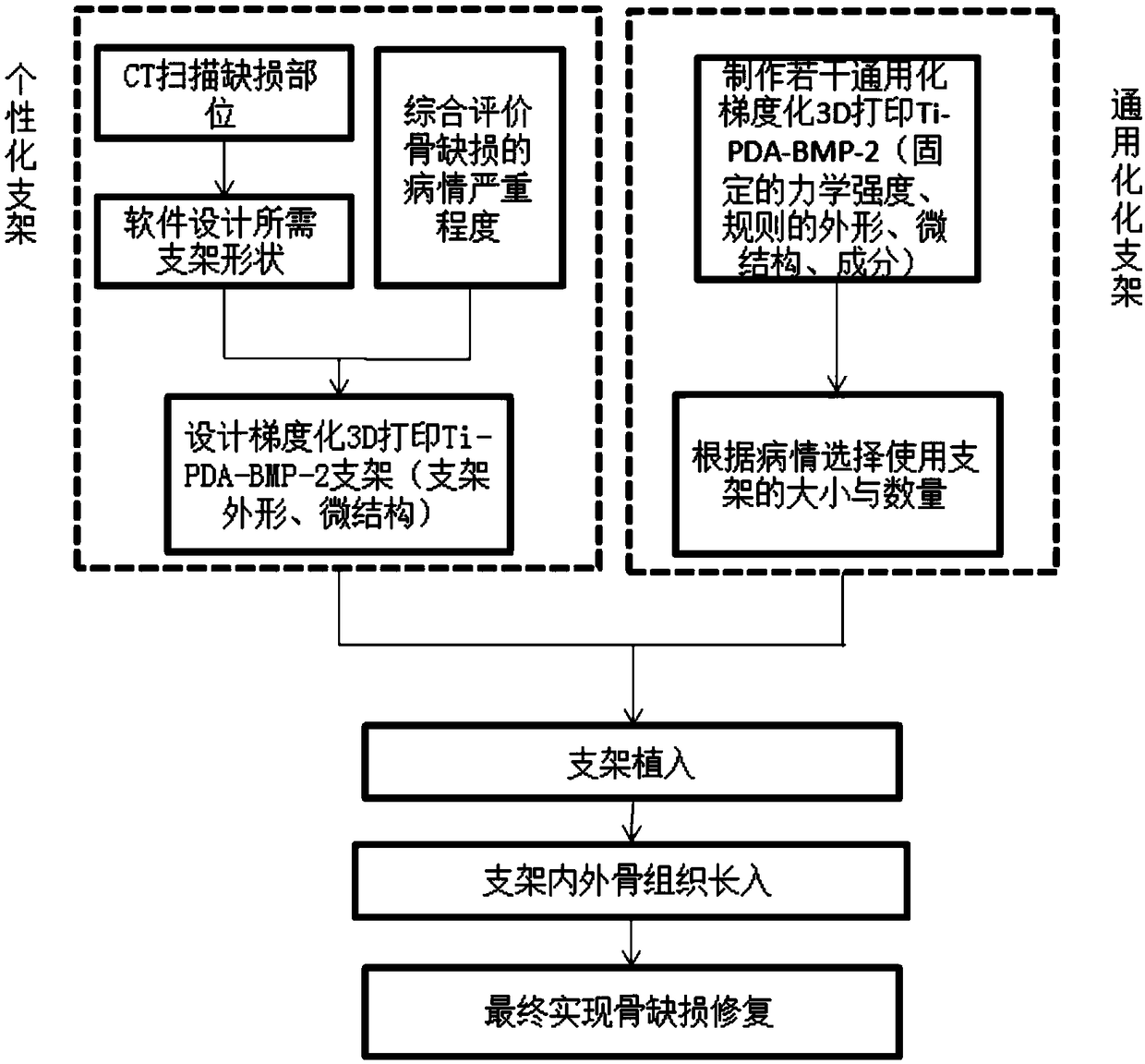

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of gradient 3D printed Ti scaffolds

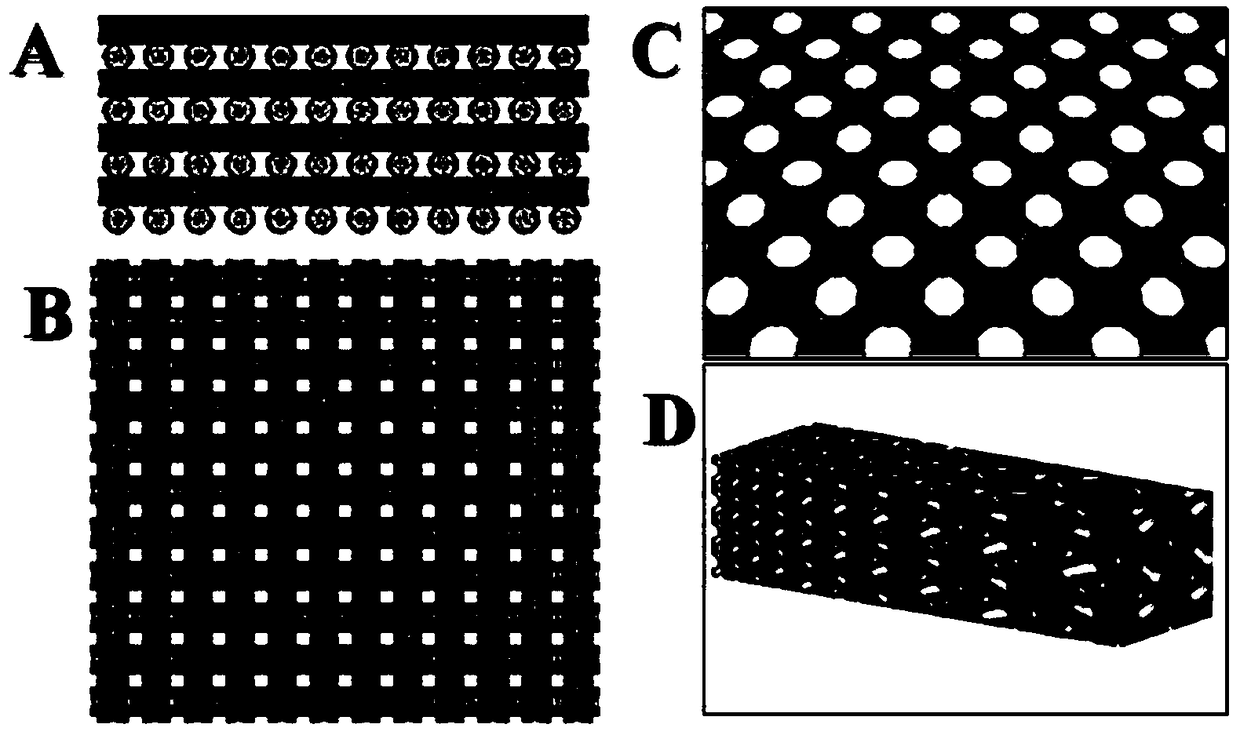

[0033] The Ti6Al4V powder is sintered by laser to form a molded fiber bundle, and the 3D printing product is obtained through the splicing structure of different layers and angles of the fiber bundle. Its shape can be 3D printed and personalized according to the shape of the bone defect in the area to be repaired. It can also be manufactured as a scaffold material with a fixed shape by SLM technology, and filled according to the actual bone defect requirements during the operation. The initial pores are 500 microns, increasing 100 microns layer by layer, such as figure 2 shown.

[0034] 2. Preparation of gradient 3D printed Ti-PDA scaffolds

[0035] After the stent structure is constructed by 3D printing, the surface is modified using PDA. The specific steps include:

[0036] 1) preparation concentration is the hydrochloric acid (HCL) solution of 0.5mol / L;

[0037] 2) Weigh 0.61g Tris and add it into 500ml water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com